INSTALLATION

Connecting to Gas Supply (Cont.) Checking Gas Connections

9

INSTALLATION

Continued

![]() WARNING: Use pipe joint sealant that is resistant to liquid petroleum (LP) gas.

WARNING: Use pipe joint sealant that is resistant to liquid petroleum (LP) gas.

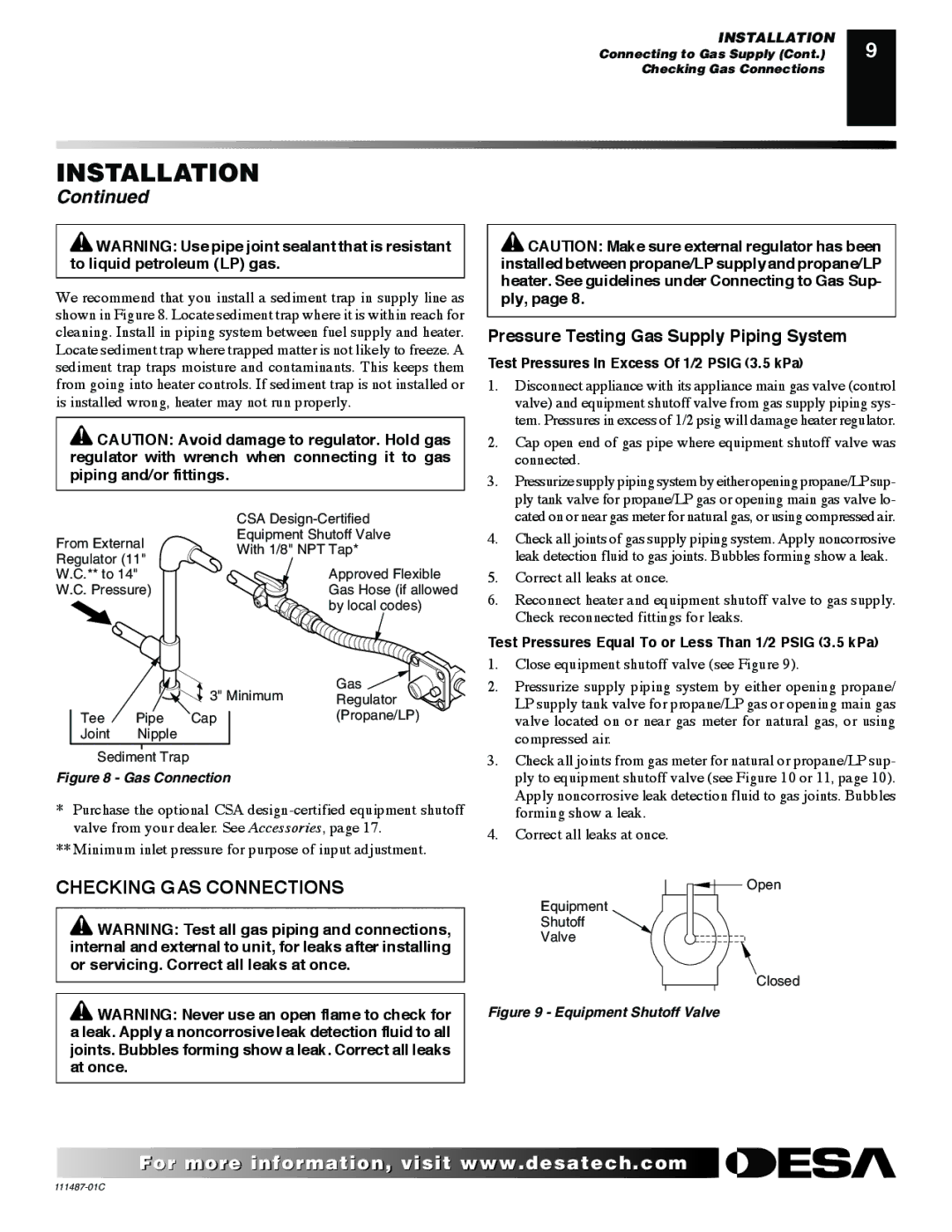

We recommend that you install a sediment trap in supply line as shown in Figure 8. Locate sediment trap where it is within reach for cleaning. Install in piping system between fuel supply and heater. Locate sediment trap where trapped matter is not likely to freeze. A sediment trap traps moisture and contaminants. This keeps them from going into heater controls. If sediment trap is not installed or is installed wrong, heater may not run properly.

![]() CAUTION: Avoid damage to regulator. Hold gas regulator with wrench when connecting it to gas piping and/or fittings.

CAUTION: Avoid damage to regulator. Hold gas regulator with wrench when connecting it to gas piping and/or fittings.

| CSA | |

From External | Equipment Shutoff Valve | |

With 1/8" NPT Tap* | ||

Regulator (11" | ||

Approved Flexible | ||

W.C.** to 14" | ||

W.C. Pressure) | Gas Hose (if allowed | |

| by local codes) |

|

| 3" Minimum | Gas |

|

| Regulator | |

Tee | Pipe | Cap | (Propane/LP) |

Joint | Nipple |

|

|

Sediment Trap

Figure 8 - Gas Connection

*Purchase the optional CSA

**Minimum inlet pressure for purpose of input adjustment.

CHECKING GAS CONNECTIONS

![]() WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

![]() WARNING: Never use an open flame to check for a leak. Apply a noncorrosive leak detection fluid to all joints. Bubbles forming show a leak. Correct all leaks at once.

WARNING: Never use an open flame to check for a leak. Apply a noncorrosive leak detection fluid to all joints. Bubbles forming show a leak. Correct all leaks at once.

![]() CAUTION: Make sure external regulator has been installed between propane/LP supply and propane/LP heater. See guidelines under Connecting to Gas Sup- ply, page 8.

CAUTION: Make sure external regulator has been installed between propane/LP supply and propane/LP heater. See guidelines under Connecting to Gas Sup- ply, page 8.

Pressure Testing Gas Supply Piping System

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1.Disconnect appliance with its appliance main gas valve (control valve) and equipment shutoff valve from gas supply piping sys- tem. Pressures in excess of 1/2 psig will damage heater regulator.

2.Cap open end of gas pipe where equipment shutoff valve was connected.

3.Pressurize supply piping system by either opening propane/LP sup- ply tank valve for propane/LP gas or opening main gas valve lo- cated on or near gas meter for natural gas, or using compressed air.

4.Check all joints of gas supply piping system. Apply noncorrosive leak detection fluid to gas joints. Bubbles forming show a leak.

5.Correct all leaks at once.

6.Reconnect heater and equipment shutoff valve to gas supply. Check reconnected fittings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1.Close equipment shutoff valve (see Figure 9).

2.Pressurize supply piping system by either opening propane/ LP supply tank valve for propane/LP gas or opening main gas valve located on or near gas meter for natural gas, or using compressed air.

3.Check all joints from gas meter for natural or propane/LP sup- ply to equipment shutoff valve (see Figure 10 or 11, page 10). Apply noncorrosive leak detection fluid to gas joints. Bubbles forming show a leak.

4.Correct all leaks at once.

Open

Equipment

Shutoff

Valve

CO losed

POS

Figure 9 - Equipment Shutoff Valve

For more![]()

![]()

![]()

![]() visit www.

visit www.![]()

![]()

![]() .com

.com![]()

![]()

![]()

![]()

![]()