OWNER’S MANUAL

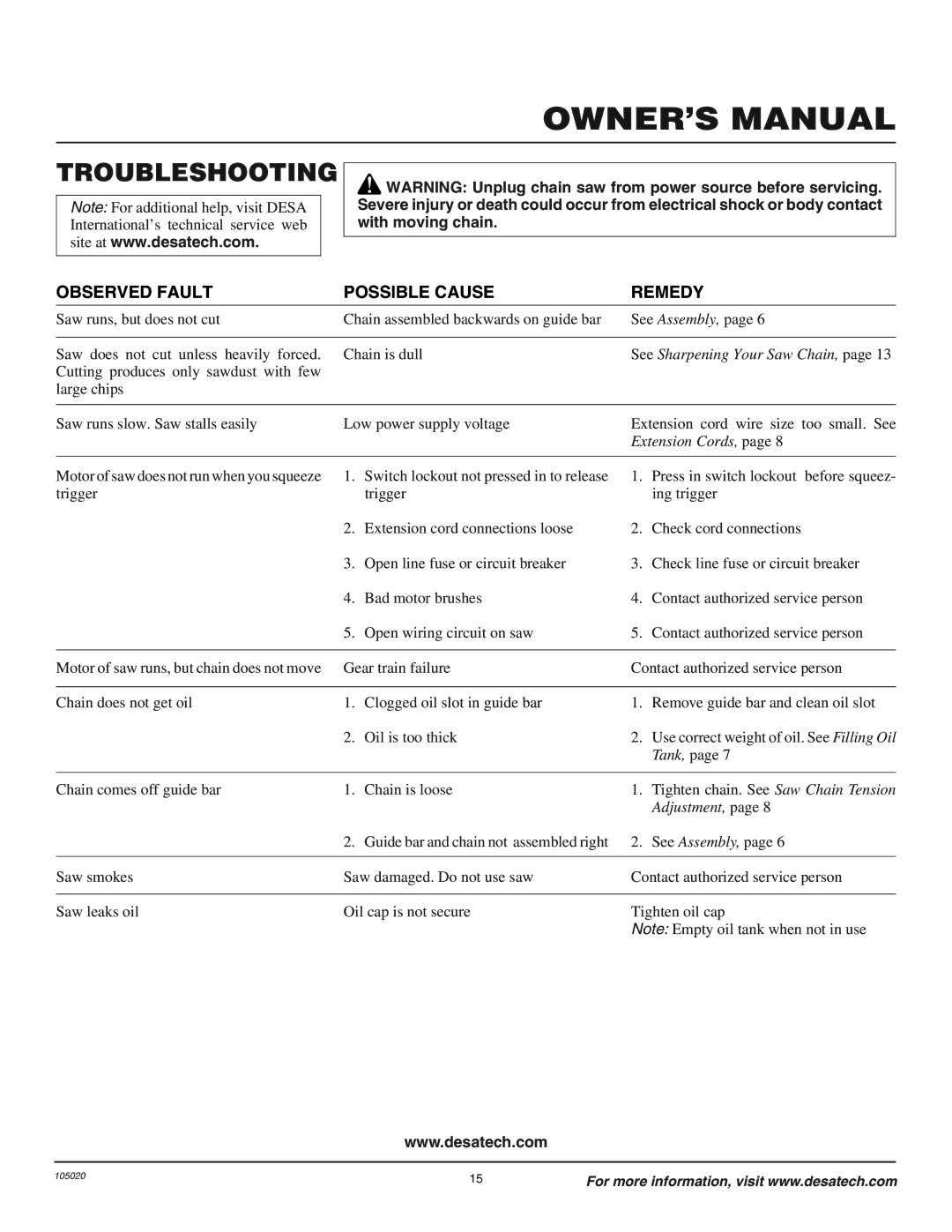

TROUBLESHOOTING

Note: For additional help, visit DESA International’s technical service web site at www.desatech.com.

![]() WARNING: Unplug chain saw from power source before servicing. Severe injury or death could occur from electrical shock or body contact with moving chain.

WARNING: Unplug chain saw from power source before servicing. Severe injury or death could occur from electrical shock or body contact with moving chain.

OBSERVED FAULT | POSSIBLE CAUSE | REMEDY |

Saw runs, but does not cut | Chain assembled backwards on guide bar | See Assembly, page 6 |

|

|

|

Saw does not cut unless heavily forced. | Chain is dull | See Sharpening Your Saw Chain, page 13 |

Cutting produces only sawdust with few |

|

|

large chips |

|

|

|

|

|

Saw runs slow. Saw stalls easily | Low power supply voltage | Extension cord wire size too small. See |

|

| Extension Cords, page 8 |

|

|

|

Motor of saw does not run when you squeeze trigger

1.Switch lockout not pressed in to release trigger

1.Press in switch lockout before squeez- ing trigger

| 2. | Extension cord connections loose | 2. | Check cord connections |

| 3. | Open line fuse or circuit breaker | 3. | Check line fuse or circuit breaker |

| 4. | Bad motor brushes | 4. | Contact authorized service person |

| 5. | Open wiring circuit on saw | 5. | Contact authorized service person |

|

|

| ||

Motor of saw runs, but chain does not move | Gear train failure | Contact authorized service person | ||

|

|

|

|

|

Chain does not get oil | 1. | Clogged oil slot in guide bar | 1. | Remove guide bar and clean oil slot |

| 2. | Oil is too thick | 2. | Use correct weight of oil. See Filling Oil |

|

|

|

| Tank, page 7 |

|

|

|

|

|

Chain comes off guide bar | 1. | Chain is loose | 1. | Tighten chain. See Saw Chain Tension |

|

|

|

| Adjustment, page 8 |

| 2. | Guide bar and chain not assembled right | 2. | See Assembly, page 6 |

|

|

| ||

Saw smokes | Saw damaged. Do not use saw | Contact authorized service person | ||

|

|

| ||

Saw leaks oil | Oil cap is not secure | Tighten oil cap | ||

|

|

| Note: Empty oil tank when not in use | |

www.desatech.com

105020 | 15 | For more information, visit www.desatech.com |

|