®

UNVENTED NATURAL GAS FIREPLACE

INSTALLATIONS

Continued

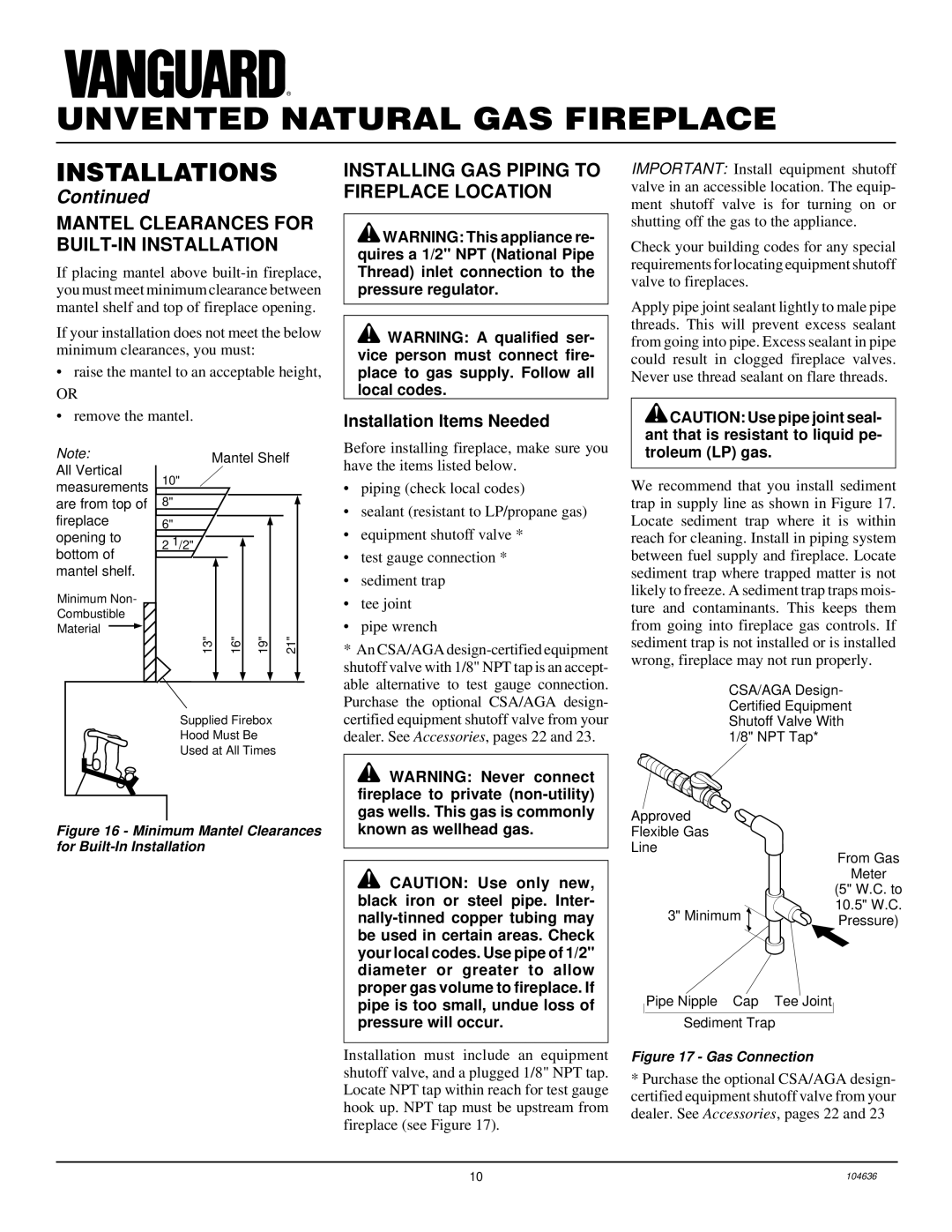

MANTEL CLEARANCES FOR BUILT-IN INSTALLATION

If placing mantel above

If your installation does not meet the below minimum clearances, you must:

•raise the mantel to an acceptable height,

OR

•remove the mantel.

Note: | Mantel Shelf | ||||

All Vertical | |||||

10" |

|

|

| ||

measurements |

|

|

| ||

are from top of | 8" |

|

|

| |

|

|

| |||

fireplace | 6" |

|

|

| |

|

|

| |||

opening to | 2 1/2" |

|

|

| |

|

|

| |||

bottom of |

|

|

| ||

|

|

|

| ||

mantel shelf. |

|

|

|

| |

Minimum Non- |

|

|

|

| |

Combustible |

|

|

|

| |

Material | 13" | 16" | 19" | 21" | |

| |||||

|

|

|

|

| |

Supplied Firebox

Hood Must Be

Used at All Times

Figure 16 - Minimum Mantel Clearances for Built-In Installation

INSTALLING GAS PIPING TO FIREPLACE LOCATION

![]() WARNING: This appliance re- quires a 1/2" NPT (National Pipe Thread) inlet connection to the pressure regulator.

WARNING: This appliance re- quires a 1/2" NPT (National Pipe Thread) inlet connection to the pressure regulator.

![]() WARNING: A qualified ser- vice person must connect fire- place to gas supply. Follow all local codes.

WARNING: A qualified ser- vice person must connect fire- place to gas supply. Follow all local codes.

Installation Items Needed

Before installing fireplace, make sure you have the items listed below.

•piping (check local codes)

•sealant (resistant to LP/propane gas)

•equipment shutoff valve *

•test gauge connection *

•sediment trap

•tee joint

•pipe wrench

*An CSA/AGA

![]() WARNING: Never connect fireplace to private

WARNING: Never connect fireplace to private

![]() CAUTION: Use only new, black iron or steel pipe. Inter-

CAUTION: Use only new, black iron or steel pipe. Inter-

Installation must include an equipment shutoff valve, and a plugged 1/8" NPT tap. Locate NPT tap within reach for test gauge hook up. NPT tap must be upstream from fireplace (see Figure 17).

IMPORTANT: Install equipment shutoff valve in an accessible location. The equip- ment shutoff valve is for turning on or shutting off the gas to the appliance.

Check your building codes for any special requirements for locating equipment shutoff valve to fireplaces.

Apply pipe joint sealant lightly to male pipe threads. This will prevent excess sealant from going into pipe. Excess sealant in pipe could result in clogged fireplace valves. Never use thread sealant on flare threads.

![]() CAUTION: Use pipe joint seal- ant that is resistant to liquid pe- troleum (LP) gas.

CAUTION: Use pipe joint seal- ant that is resistant to liquid pe- troleum (LP) gas.

We recommend that you install sediment trap in supply line as shown in Figure 17. Locate sediment trap where it is within reach for cleaning. Install in piping system between fuel supply and fireplace. Locate sediment trap where trapped matter is not likely to freeze. A sediment trap traps mois- ture and contaminants. This keeps them from going into fireplace gas controls. If sediment trap is not installed or is installed wrong, fireplace may not run properly.

CSA/AGA Design-

Certified Equipment

Shutoff Valve With

1/8" NPT Tap*

Approved |

| |

Flexible Gas |

| |

Line | From Gas | |

| ||

| Meter | |

| (5" W.C. to | |

3" Minimum | 10.5" W.C. | |

Pressure) | ||

|

Pipe Nipple Cap Tee Joint

Sediment Trap

Figure 17 - Gas Connection

*Purchase the optional CSA/AGA design- certified equipment shutoff valve from your dealer. See Accessories, pages 22 and 23

10 | 104636 |