20

TROUBLESHOOTING

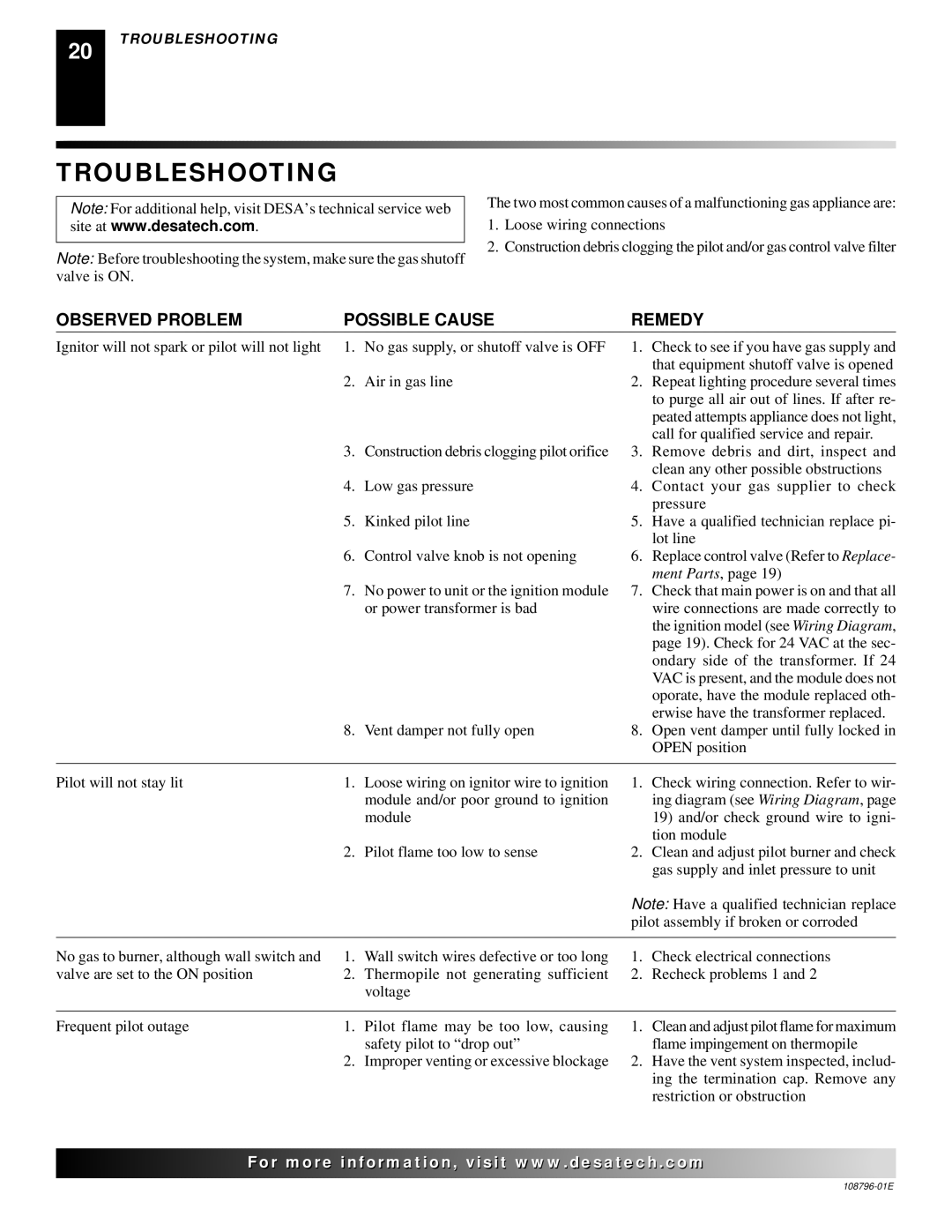

TROUBLESHOOTING

Note: For additional help, visit DESA’s technical service web site at www.desatech.com.

Note: Before troubleshooting the system, make sure the gas shutoff valve is ON.

The two most common causes of a malfunctioning gas appliance are:

1.Loose wiring connections

2.Construction debris clogging the pilot and/or gas control valve filter

OBSERVED PROBLEM | POSSIBLE CAUSE | REMEDY | ||

Ignitor will not spark or pilot will not light | 1. | No gas supply, or shutoff valve is OFF | 1. | Check to see if you have gas supply and |

|

|

|

| that equipment shutoff valve is opened |

| 2. | Air in gas line | 2. | Repeat lighting procedure several times |

|

|

|

| to purge all air out of lines. If after re- |

|

|

|

| peated attempts appliance does not light, |

|

|

|

| call for qualified service and repair. |

| 3. | Construction debris clogging pilot orifice | 3. | Remove debris and dirt, inspect and |

|

|

|

| clean any other possible obstructions |

| 4. | Low gas pressure | 4. | Contact your gas supplier to check |

|

|

|

| pressure |

| 5. | Kinked pilot line | 5. | Have a qualified technician replace pi- |

|

|

|

| lot line |

| 6. | Control valve knob is not opening | 6. | Replace control valve (Refer to Replace- |

|

|

|

| ment Parts, page 19) |

| 7. | No power to unit or the ignition module | 7. | Check that main power is on and that all |

|

| or power transformer is bad |

| wire connections are made correctly to |

|

|

|

| the ignition model (see Wiring Diagram, |

|

|

|

| page 19). Check for 24 VAC at the sec- |

|

|

|

| ondary side of the transformer. If 24 |

|

|

|

| VAC is present, and the module does not |

|

|

|

| oporate, have the module replaced oth- |

|

|

|

| erwise have the transformer replaced. |

| 8. | Vent damper not fully open | 8. | Open vent damper until fully locked in |

|

|

|

| OPEN position |

|

|

|

|

|

Pilot will not stay lit | 1. | Loose wiring on ignitor wire to ignition | 1. | Check wiring connection. Refer to wir- |

|

| module and/or poor ground to ignition |

| ing diagram (see Wiring Diagram, page |

|

| module |

| 19) and/or check ground wire to igni- |

|

|

|

| tion module |

| 2. | Pilot flame too low to sense | 2. | Clean and adjust pilot burner and check |

|

|

|

| gas supply and inlet pressure to unit |

|

|

| Note: Have a qualified technician replace | |

|

|

| pilot assembly if broken or corroded | |

|

|

|

|

|

No gas to burner, although wall switch and | 1. | Wall switch wires defective or too long | 1. | Check electrical connections |

valve are set to the ON position | 2. | Thermopile not generating sufficient | 2. | Recheck problems 1 and 2 |

|

| voltage |

|

|

|

|

|

|

|

Frequent pilot outage | 1. | Pilot flame may be too low, causing | 1. | Clean and adjust pilot flame for maximum |

|

| safety pilot to “drop out” |

| flame impingement on thermopile |

| 2. | Improper venting or excessive blockage | 2. | Have the vent system inspected, includ- |

|

|

|

| ing the termination cap. Remove any |

|

|

|

| restriction or obstruction |

For more |

| visit www. |

| .com |