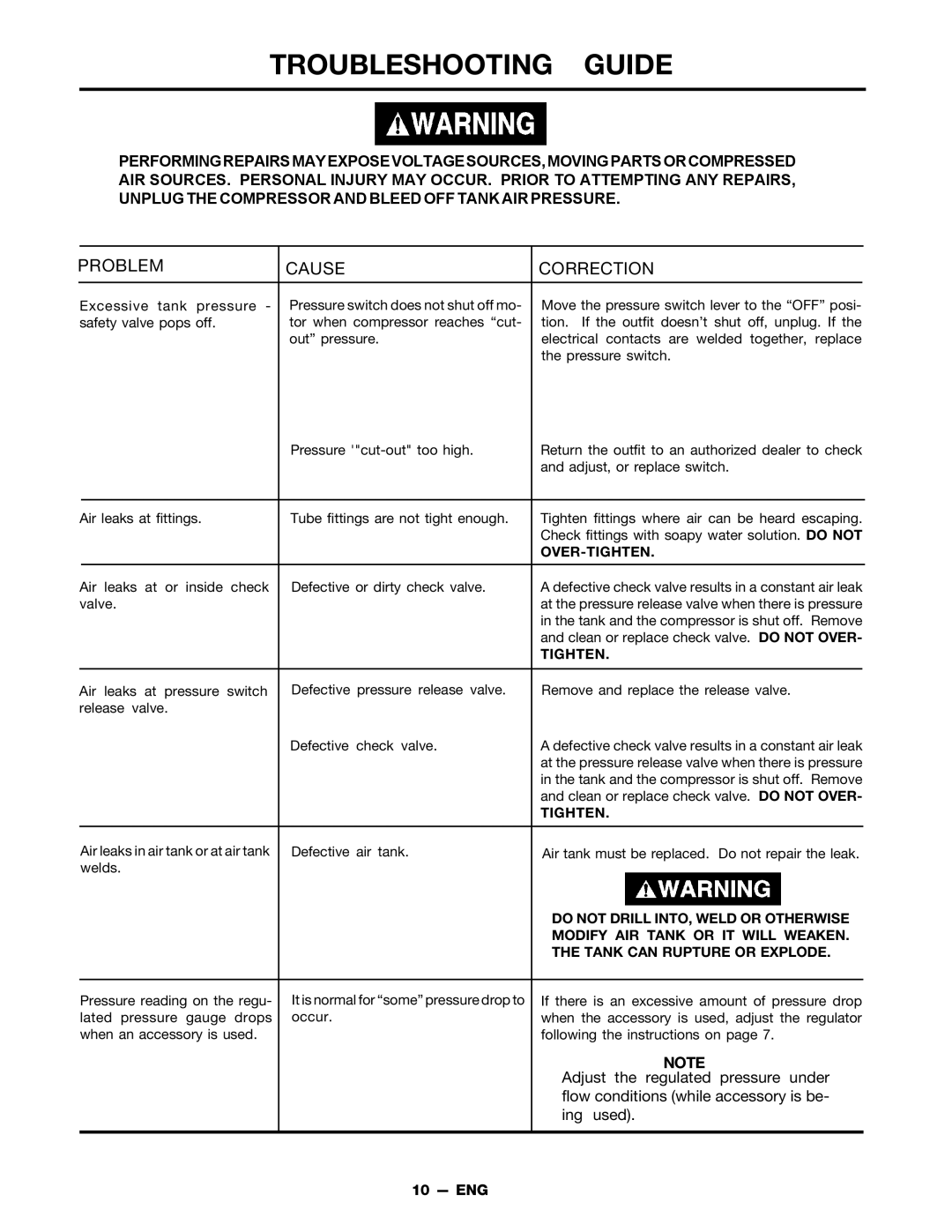

TROUBLESHOOTING GUIDE

PERFORMINGREPAIRSMAYEXPOSEVOLTAGESOURCES,MOVINGPARTSORCOMPRESSED AIR SOURCES. PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY REPAIRS, UNPLUG THE COMPRESSOR AND BLEED OFF TANK AIR PRESSURE.

PROBLEM | CAUSE | CORRECTION |

|

|

|

Excessive tank pressure - | Pressure switch does not shut off mo- | Move the pressure switch lever to the “OFF” posi- |

safety valve pops off. | tor when compressor reaches “cut- | tion. If the outfit doesn’t shut off, unplug. If the |

| out” pressure. | electrical contacts are welded together, replace |

|

| the pressure switch. |

|

| Pressure | Return the outfit to an authorized dealer to check | |

|

|

| and adjust, or replace switch. | |

|

|

|

|

|

Air leaks at fittings. | Tube fittings are not tight enough. | Tighten fittings where air can be heard escaping. | ||

|

|

| Check fittings with soapy water solution. DO NOT | |

|

|

|

| |

|

|

|

|

|

Air leaks at or inside check | Defective or dirty check valve. | A defective check valve results in a constant air leak | ||

valve. |

| at the pressure release valve when there is pressure | ||

|

|

| in the tank and the compressor is shut off. Remove | |

|

|

| and clean or replace check valve. DO NOT OVER- | |

|

|

| TIGHTEN. | |

|

|

|

| |

Air leaks at pressure switch | Defective pressure release valve. | Remove and replace the release valve. | ||

release valve. |

|

|

| |

|

| Defective check valve. | A defective check valve results in a constant air leak | |

|

|

| at the pressure release valve when there is pressure | |

|

|

| in the tank and the compressor is shut off. Remove | |

|

|

| and clean or replace check valve. DO NOT OVER- | |

|

|

| TIGHTEN. | |

|

|

|

| |

Air leaks in air tank or at air tank | Defective air tank. | Air tank must be replaced. Do not repair the leak. | ||

welds. |

|

|

| |

|

|

| DO NOT DRILL INTO, WELD OR OTHERWISE | |

|

|

| MODIFY AIR TANK OR IT WILL WEAKEN. | |

|

|

| THE TANK CAN RUPTURE OR EXPLODE. | |

|

|

|

| |

Pressure reading on the regu- | It is normal for “some” pressure drop to | If there is an excessive amount of pressure drop | ||

lated pressure gauge drops | occur. | when the accessory is used, adjust the regulator | ||

when an accessory is used. |

| following the instructions on page 7. | ||

|

|

| NOTE | |

|

|

| Adjust the regulated pressure under | |

|

|

| flow conditions (while accessory is be- | |

|

|

| ing used). | |

10 — ENG