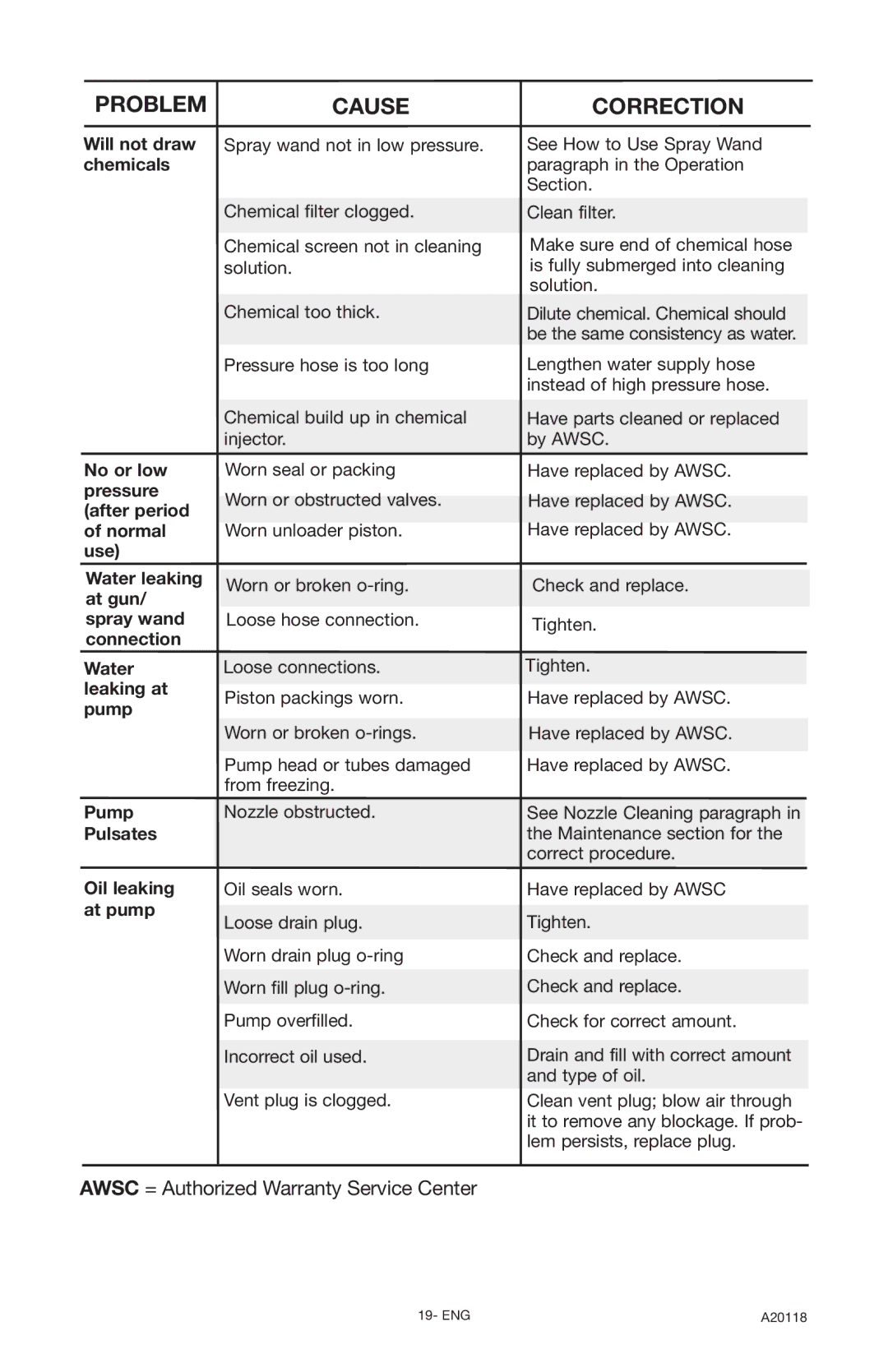

PROBLEM

Will not draw chemicals

No or low pressure (after period of normal use)

Water leaking at gun/ spray wand connection

Water leaking at pump

Pump

Pulsates

Oil leaking at pump

CAUSE

Spray wand not in low pressure.

Chemical filter clogged.

Chemical screen not in cleaning solution.

Chemical too thick.

Pressure hose is too long

Chemical build up in chemical injector.

Worn seal or packing Worn or obstructed valves. Worn unloader piston.

Worn or broken

Loose hose connection.

Loose connections.

Piston packings worn.

Worn or broken

Pump head or tubes damaged from freezing.

Nozzle obstructed.

Oil seals worn.

Loose drain plug.

Worn drain plug

Worn fill plug

Pump overfilled.

Incorrect oil used.

Vent plug is clogged.

CORRECTION

See How to Use Spray Wand paragraph in the Operation Section.

Clean filter.

Make sure end of chemical hose is fully submerged into cleaning solution.

Dilute chemical. Chemical should be the same consistency as water.

Lengthen water supply hose instead of high pressure hose.

Have parts cleaned or replaced by AWSC.

Have replaced by AWSC.

Have replaced by AWSC.

Have replaced by AWSC.

Check and replace.

Tighten.

Tighten.

Have replaced by AWSC.

Have replaced by AWSC.

Have replaced by AWSC.

See Nozzle Cleaning paragraph in the Maintenance section for the correct procedure.

Have replaced by AWSC

Tighten.

Check and replace.

Check and replace.

Check for correct amount.

Drain and fill with correct amount and type of oil.

Clean vent plug; blow air through it to remove any blockage. If prob- lem persists, replace plug.

AWSC = Authorized Warranty Service Center

19- ENG | A20118 |