CHANGING SPEEDS

DISCONNECT MACHINE FROM POWER SOURCE.

DISCONNECT MACHINE FROM POWER SOURCE.

1. | Open the bottom access door (See D, Fig. 26). |

|

| E |

|

|

|

| |||

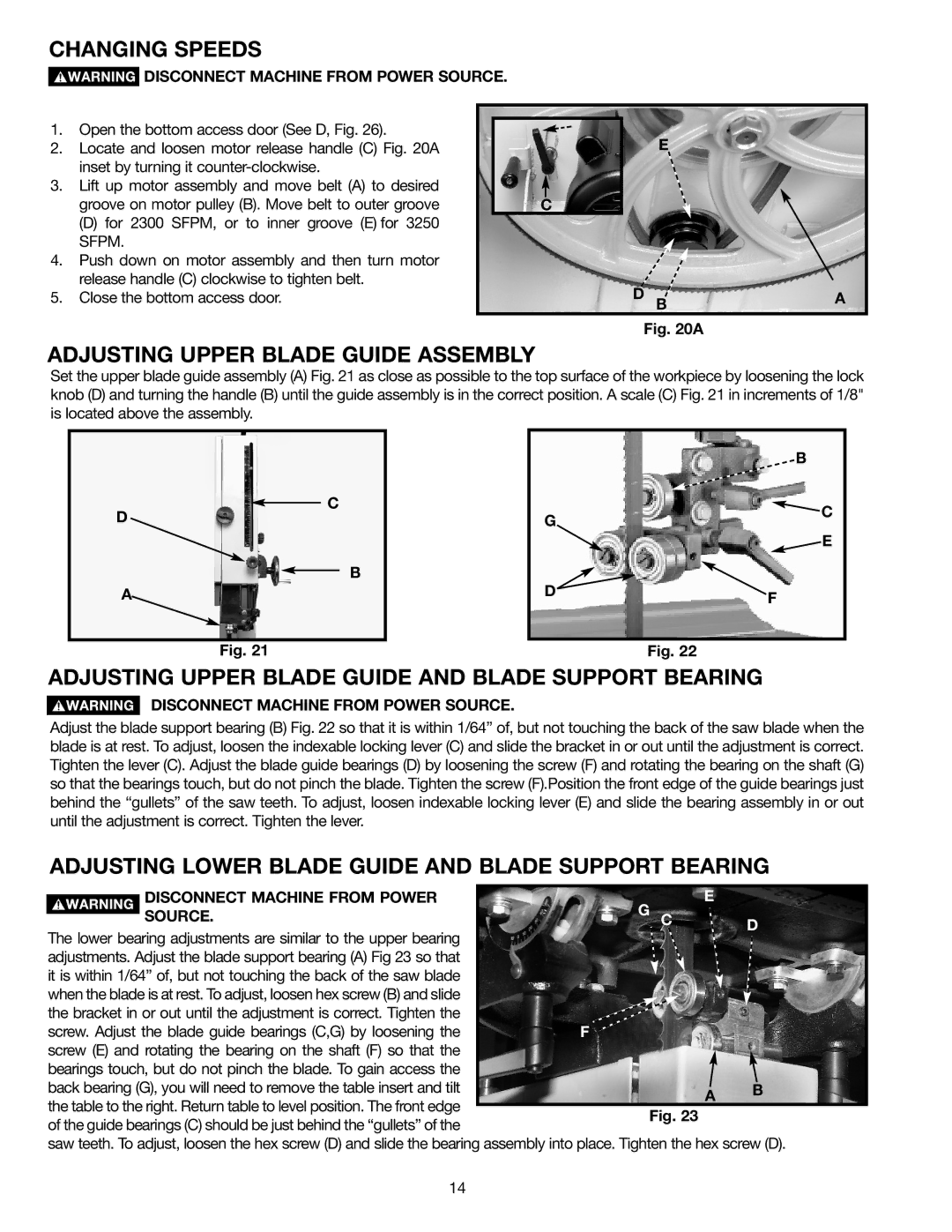

2. | Locate and loosen motor release handle (C) Fig. 20A |

|

|

| |

| inset by turning it |

|

|

|

|

3. | Lift up motor assembly and move belt (A) to desired |

|

|

|

|

| groove on motor pulley (B). Move belt to outer groove |

| C |

|

|

| (D) for 2300 SFPM, or to inner groove (E) for 3250 |

|

|

|

|

| SFPM. |

|

|

|

|

4. | Push down on motor assembly and then turn motor |

|

|

|

|

| release handle (C) clockwise to tighten belt. |

|

| D |

|

5. | Close the bottom access door. |

|

| A | |

|

|

|

| B |

|

|

|

|

| Fig. 20A |

|

ADJUSTING UPPER BLADE GUIDE ASSEMBLY

Set the upper blade guide assembly (A) Fig. 21 as close as possible to the top surface of the workpiece by loosening the lock knob (D) and turning the handle (B) until the guide assembly is in the correct position. A scale (C) Fig. 21 in increments of 1/8" is located above the assembly.

C

D

B

A

Fig. 21

B

G | C |

| |

| E |

D | F |

| |

| Fig. 22 |

ADJUSTING UPPER BLADE GUIDE AND BLADE SUPPORT BEARING

DISCONNECT MACHINE FROM POWER SOURCE.

Adjust the blade support bearing (B) Fig. 22 so that it is within 1/64” of, but not touching the back of the saw blade when the blade is at rest. To adjust, loosen the indexable locking lever (C) and slide the bracket in or out until the adjustment is correct. Tighten the lever (C). Adjust the blade guide bearings (D) by loosening the screw (F) and rotating the bearing on the shaft (G) so that the bearings touch, but do not pinch the blade. Tighten the screw (F).Position the front edge of the guide bearings just behind the “gullets” of the saw teeth. To adjust, loosen indexable locking lever (E) and slide the bearing assembly in or out until the adjustment is correct. Tighten the lever.

ADJUSTING LOWER BLADE GUIDE AND BLADE SUPPORT BEARING

|

|

| DISCONNECT MACHINE FROM POWER | G C | E |

|

|

|

|

| |||

|

|

|

| |||

|

|

| SOURCE. |

| D | |

|

|

|

| |||

|

|

|

| |||

The lower bearing adjustments are similar to the upper bearing |

|

| ||||

|

|

| ||||

adjustments. Adjust the blade support bearing (A) Fig 23 so that |

|

|

| |||

it is within 1/64” of, but not touching the back of the saw blade |

|

|

| |||

when the blade is at rest. To adjust, loosen hex screw (B) and slide |

|

|

| |||

the bracket in or out until the adjustment is correct. Tighten the |

|

|

| |||

screw. Adjust the blade guide bearings (C,G) by loosening the | F |

|

| |||

screw (E) and rotating the bearing on the shaft (F) so that the |

|

|

| |||

bearings touch, but do not pinch the blade. To gain access the |

|

|

| |||

back bearing (G), you will need to remove the table insert and tilt |

| A | B | |||

the table to the right. Return table to level position. The front edge |

|

| ||||

Fig. 23 |

|

| ||||

of the guide bearings (C) should be just behind the “gullets” of the |

|

| ||||

|

|

| ||||

saw teeth. To adjust, loosen the hex screw (D) and slide the bearing assembly into place. Tighten the hex screw (D).

14