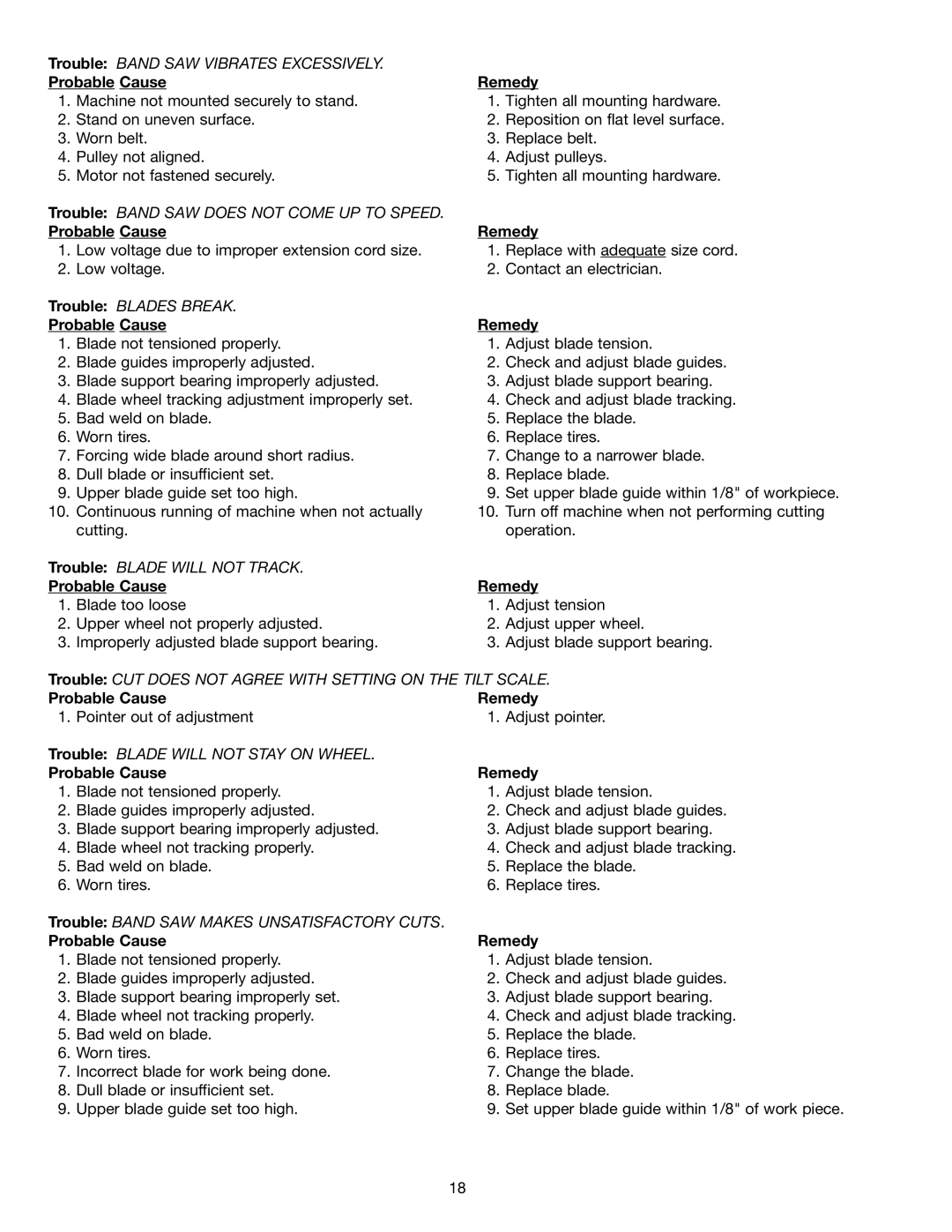

Trouble: BAND SAW VIBRATES EXCESSIVELY.

Probable Cause

1.Machine not mounted securely to stand.

2.Stand on uneven surface.

3.Worn belt.

4.Pulley not aligned.

5.Motor not fastened securely.

Trouble: BAND SAW DOES NOT COME UP TO SPEED.

Probable Cause

1.Low voltage due to improper extension cord size.

2.Low voltage.

Trouble: BLADES BREAK.

Probable Cause

1.Blade not tensioned properly.

2.Blade guides improperly adjusted.

3.Blade support bearing improperly adjusted.

4.Blade wheel tracking adjustment improperly set.

5.Bad weld on blade.

6.Worn tires.

7.Forcing wide blade around short radius.

8.Dull blade or insufficient set.

9.Upper blade guide set too high.

10.Continuous running of machine when not actually cutting.

Trouble: BLADE WILL NOT TRACK.

Probable Cause

1.Blade too loose

2.Upper wheel not properly adjusted.

3.Improperly adjusted blade support bearing.

Remedy

1.Tighten all mounting hardware.

2.Reposition on flat level surface.

3.Replace belt.

4.Adjust pulleys.

5.Tighten all mounting hardware.

Remedy

1.Replace with adequate size cord.

2.Contact an electrician.

Remedy

1.Adjust blade tension.

2.Check and adjust blade guides.

3.Adjust blade support bearing.

4.Check and adjust blade tracking.

5.Replace the blade.

6.Replace tires.

7.Change to a narrower blade.

8.Replace blade.

9.Set upper blade guide within 1/8" of workpiece.

10.Turn off machine when not performing cutting operation.

Remedy

1.Adjust tension

2.Adjust upper wheel.

3.Adjust blade support bearing.

Trouble: CUT DOES NOT AGREE WITH SETTING ON THE TILT SCALE.

Probable Cause | Remedy |

1. Pointer out of adjustment | 1. Adjust pointer. |

Trouble: BLADE WILL NOT STAY ON WHEEL.

Probable Cause

1.Blade not tensioned properly.

2.Blade guides improperly adjusted.

3.Blade support bearing improperly adjusted.

4.Blade wheel not tracking properly.

5.Bad weld on blade.

6.Worn tires.

Trouble: BAND SAW MAKES UNSATISFACTORY CUTS.

Probable Cause

1.Blade not tensioned properly.

2.Blade guides improperly adjusted.

3.Blade support bearing improperly set.

4.Blade wheel not tracking properly.

5.Bad weld on blade.

6.Worn tires.

7.Incorrect blade for work being done.

8.Dull blade or insufficient set.

9.Upper blade guide set too high.

Remedy

1.Adjust blade tension.

2.Check and adjust blade guides.

3.Adjust blade support bearing.

4.Check and adjust blade tracking.

5.Replace the blade.

6.Replace tires.

Remedy

1.Adjust blade tension.

2.Check and adjust blade guides.

3.Adjust blade support bearing.

4.Check and adjust blade tracking.

5.Replace the blade.

6.Replace tires.

7.Change the blade.

8.Replace blade.

9.Set upper blade guide within 1/8" of work piece.

18