Patent Notification

Manufactured under one or more of the following U.S. patents:

6,431,040 5,582,089

6,427,570 5,375,495

D454,577 5,285,708

5,819,619 5,199,343 Other patents pending.

Troubleshooting Guide

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE! | WHAT’S WRONG? | WHAT TO DO | ||

Saw will not start | 1. Saw not plugged in | 1. | Plug in saw. | |

| 2. | Fuse blown or circuit breaker tripped | 2. | Replace fuse or reset circuit breaker. |

| 3. | Cord damaged | 3. | Have cord replaced by authorized service center. |

| 4. | Brushes worn out | 4. | Have brushes replaced by authorized service center or replace them yourself. Refer to Brushes. |

Saw makes | 1. Dull blade | 1. | Replace blade. Refer to Changing or Installing a New Saw Blade. | |

unsatisfactory cuts | 2. | Blade mounted backwards | 2. | Turn blade around. Refer to Changing or Installing a New Saw Blade. |

| ||||

| 3. | Gum or pitch on blade | 3. | Remove blade and clean with turpentine and coarse steel wool or household oven cleaner. |

| 4. | Incorrect blade for work being done | 4. | Change the blade type. Refer to Saw Blades. |

Blade does not come up | 1. Extension cord too light or too long | 1. | Replace with adequate size cord. Refer to Use Proper Extension Cord under Important Safety | |

to speed |

|

|

| Instructions. |

| 2. | Low house current | 2. | Contact your electric company. |

Machine vibrates excessively | 1. Saw not mounted securely to stand or | 1. | Tighten all mounting hardware. Refer to Bench Mounting. | |

|

| work bench |

|

|

| 2. | Stand or bench on uneven floor | 2. | Reposition on flat level surface. Refer to Familiarization. |

| 3. | Damaged saw blade | 3. | Replace blade. Refer to Changing or Installing a New Saw Blade. |

Does not make accurate | 1. Miter scale not adjusted correctly | 1. | Check and adjust. Refer to Miter Scale Adjustment under Adjustments. | |

miter cuts | 2. | Miter pointer not adjusted correctly | 2. | Check and adjust. Refer to Miter Pointer Adjustment under Adjustments. |

| ||||

| 3. | Workpiece is not perpendicular to table | 3. | Check and adjust fence. Refer to Fence Adjustment under Adjustments. |

| 4. | Workpiece moving | 4. | Clamp workpiece securely to fence or glue 120 grit sandpaper to fence with rubber cement. |

Material pinches blade | 1. Cutting bowed material | 1. | Refer to Bowed Material under Special Cuts. | |

|

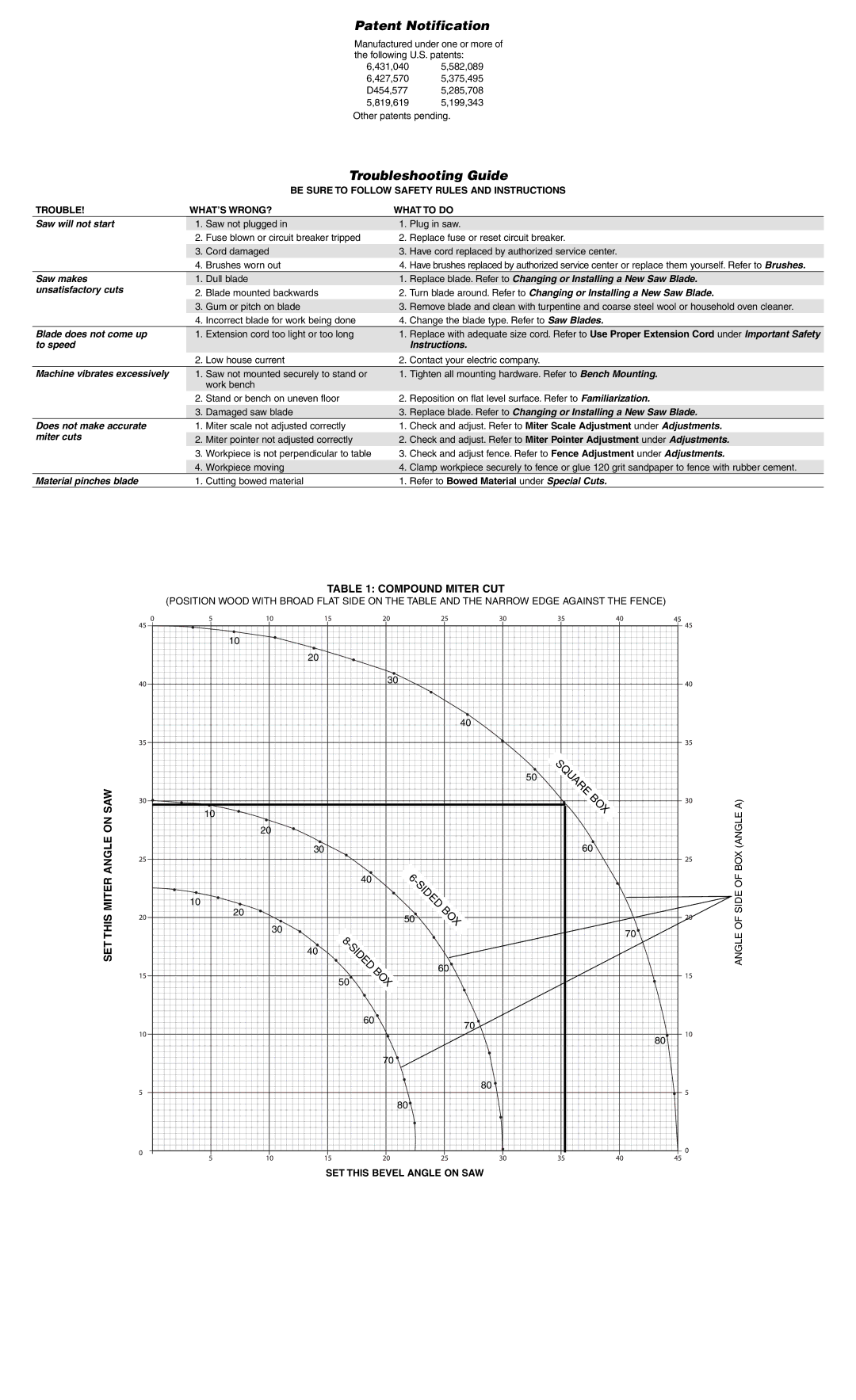

| TABLE 1: COMPOUND MITER CUT |

|

| |||

| (POSITION WOOD WITH BROAD FLAT SIDE ON THE TABLE AND THE NARROW EDGE AGAINST THE FENCE) |

| |||||

| 10 |

|

|

|

|

|

|

| 20 |

|

|

|

|

|

|

|

|

|

| 30 |

|

|

|

|

|

|

|

| 40 |

|

|

|

|

|

|

| 50 | SQUARE |

|

|

|

|

|

|

|

| |

ANGLEMITERON SAW | 10 |

|

|

|

| BOX | (ANGLEBOXOFSIDE A) |

|

|

|

|

| |||

20 |

|

|

|

|

| ||

|

|

|

|

|

|

| |

| 30 |

|

|

|

| 60 |

|

|

|

| 40 | 6 |

|

|

|

|

|

| - |

|

|

| |

| 10 |

|

| SIDED |

|

| |

THISSET | 20 |

|

| 50 | BOX |

| ANGLEOF |

|

|

|

|

| |||

30 |

|

|

|

| 70 | ||

|

|

|

|

|

| ||

|

| 8 |

|

|

|

| |

|

|

|

|

|

|

| |

|

| - |

|

|

|

|

|

| 40 | SIDED |

|

|

|

| |

|

|

|

|

|

|

| |

|

|

| BOX | 60 |

|

| |

|

| 50 |

|

|

| ||

|

|

|

|

|

|

| |

|

|

| 60 |

| 70 |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| 80 |

|

|

|

|

| 70 |

|

|

|

|

|

|

|

| 80 |

|

|

|

|

|

| 80 |

|

|

|