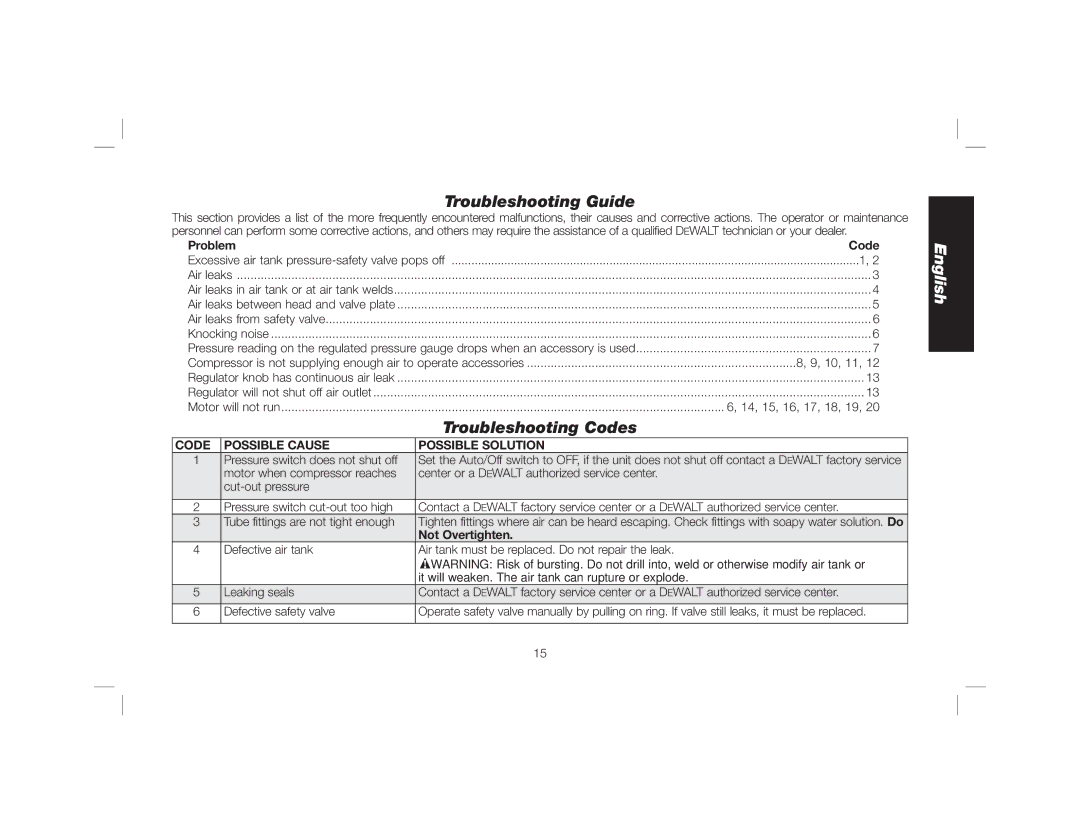

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or maintenance personnel can perform some corrective actions, and others may require the assistance of a qualified DEWALT technician or your dealer.

Problem | Code |

Excessive air tank | 1, 2 |

Air leaks | 3 |

Air leaks in air tank or at air tank welds | 4 |

Air leaks between head and valve plate | 5 |

Air leaks from safety valve | 6 |

Knocking noise | 6 |

Pressure reading on the regulated pressure gauge drops when an accessory is used | 7 |

Compressor is not supplying enough air to operate accessories | 8, 9, 10, 11, 12 |

Regulator knob has continuous air leak | 13 |

Regulator will not shut off air outlet | 13 |

Motor will not run | 6, 14, 15, 16, 17, 18, 19, 20 |

|

| Troubleshooting Codes |

CODE | POSSIBLE CAUSE | POSSIBLE SOLUTION |

1 | Pressure switch does not shut off | Set the Auto/Off switch to OFF, if the unit does not shut off contact a DEWALT factory service |

| motor when compressor reaches | center or a DEWALT authorized service center. |

|

| |

|

|

|

2 | Pressure switch | Contact a DEWALT factory service center or a DEWALT authorized service center. |

3 | Tube fittings are not tight enough | Tighten fittings where air can be heard escaping. Check fittings with soapy water solution. Do |

|

| Not Overtighten. |

4 | Defective air tank | Air tank must be replaced. Do not repair the leak. |

|

| WARNING: Risk of bursting. Do not drill into, weld or otherwise modify air tank or |

|

| it will weaken. The air tank can rupture or explode. |

5 | Leaking seals | Contact a DEWALT factory service center or a DEWALT authorized service center. |

|

|

|

6 | Defective safety valve | Operate safety valve manually by pulling on ring. If valve still leaks, it must be replaced. |

|

|

|

|

| 15 |