800 specifications

The Dremel 800 is a versatile rotary tool that stands out in the world of crafting, woodworking, and DIY projects. With its robust design and powerful performance, it is an essential tool for both hobbyists and professionals looking to undertake intricate tasks with precision.One of the main features of the Dremel 800 is its variable speed control, allowing users to select the exact RPM needed for their specific task. Ranging from 5,000 to 35,000 RPM, this flexibility enables users to work on materials ranging from soft plastic to hard metals without compromising on efficiency or quality. The ergonomic design of the tool ensures comfort during prolonged use, minimizing user fatigue.

Dremel has integrated advanced technologies into the 800 model to enhance its functionality. The EZ Twist nose cap allows for easy accessory changes without the need for additional tools, which significantly speeds up workflow. The tool's compatibility with a wide variety of Dremel accessories—from cutting wheels and sanding bands to engraving bits—makes it a truly multifunctional device for various applications.

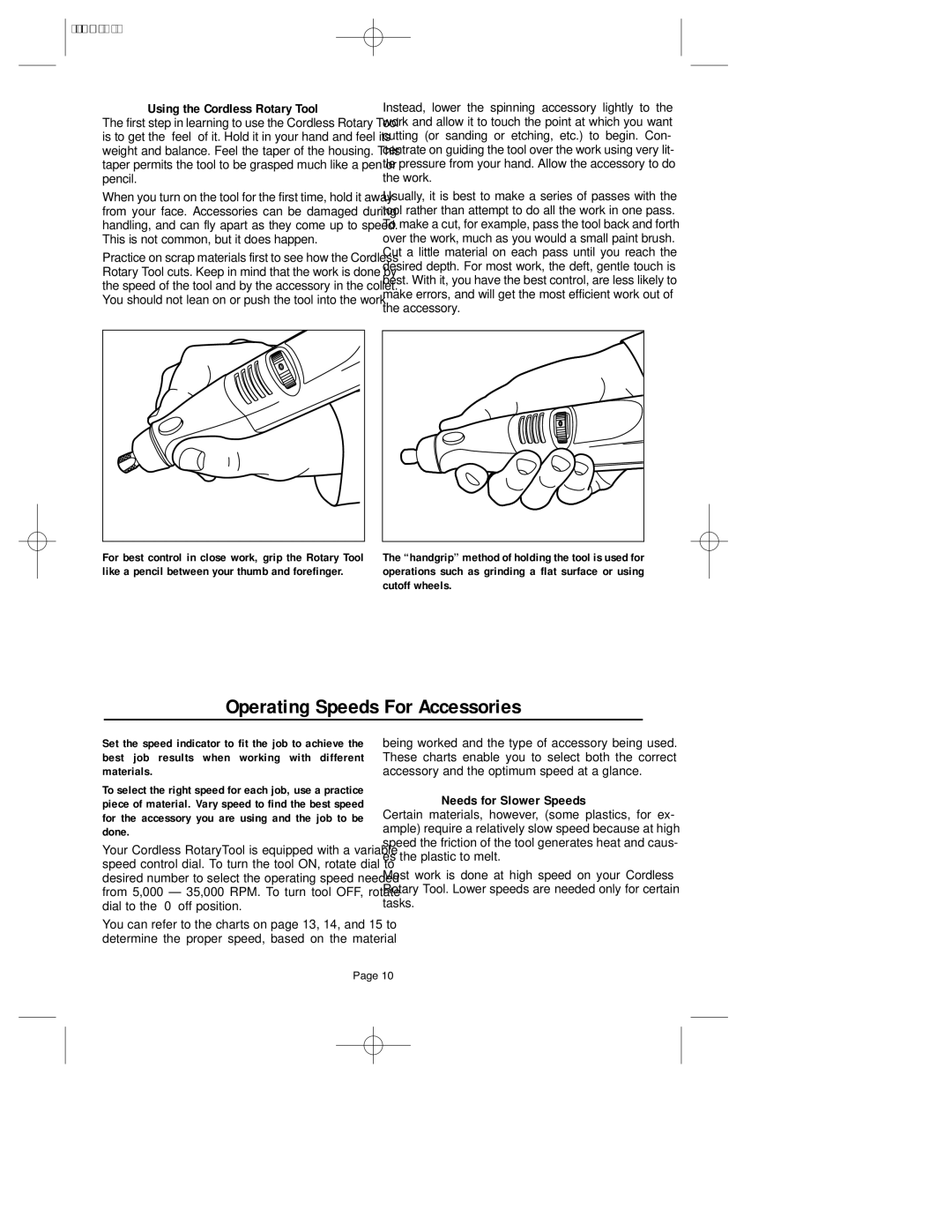

Another noteworthy characteristic is its lightweight and compact design, which makes it easy to handle and maneuver during intricate tasks. This is particularly beneficial for detailed work, such as engraving fine patterns or sanding in tight spaces where larger tools would be cumbersome.

The Dremel 800 also boasts a cooling system that helps prevent overheating during extended use. This feature promotes durability and ensures that the tool maintains optimal performance even when tackling demanding projects. Additionally, its relatively quiet operation enhances the user experience, allowing for work in more noise-sensitive environments.

Moreover, safety features such as the protective shield and a secure grip contribute to a secure and controlled experience, reducing the risk of accidents during operation. The Dremel 800 serves as an ideal tool for various applications, including home repairs, crafting, jewelry making, and DIY projects.

In summary, the Dremel 800 is characterized by its powerful variable speed, easy accessory changes, lightweight design, and durability. These features, combined with advanced technologies, make it an invaluable asset for anyone looking to elevate their crafting and DIY capabilities. Whether you are a novice or a seasoned artisan, the Dremel 800 provides the precision and convenience needed to bring your creative visions to life.