SPARK ARRESTOR MUFFLER

•The spark arrestor muffler controls the exhaust noise and prevents hot, glowing particles of carbon from leaving the muffler. Make sure the spark arrestor screen is in good repair and prop- erly seated in the muffler.

•Certain internal combustion engines operated on forest, brush, and/or

Minnesota, New Jersey and Maine, are required to be equipped with a spark arrestor.

This requirement also applies to all U.S. Forest Service lands.

In some of these areas, the spark arrestor system must be certified per USDA Forest Service Regula- tion SAE J335.

Check with your local or state authorities for spe- cific regulations in your area.

Failure to follow these requirements is a violation of the law.

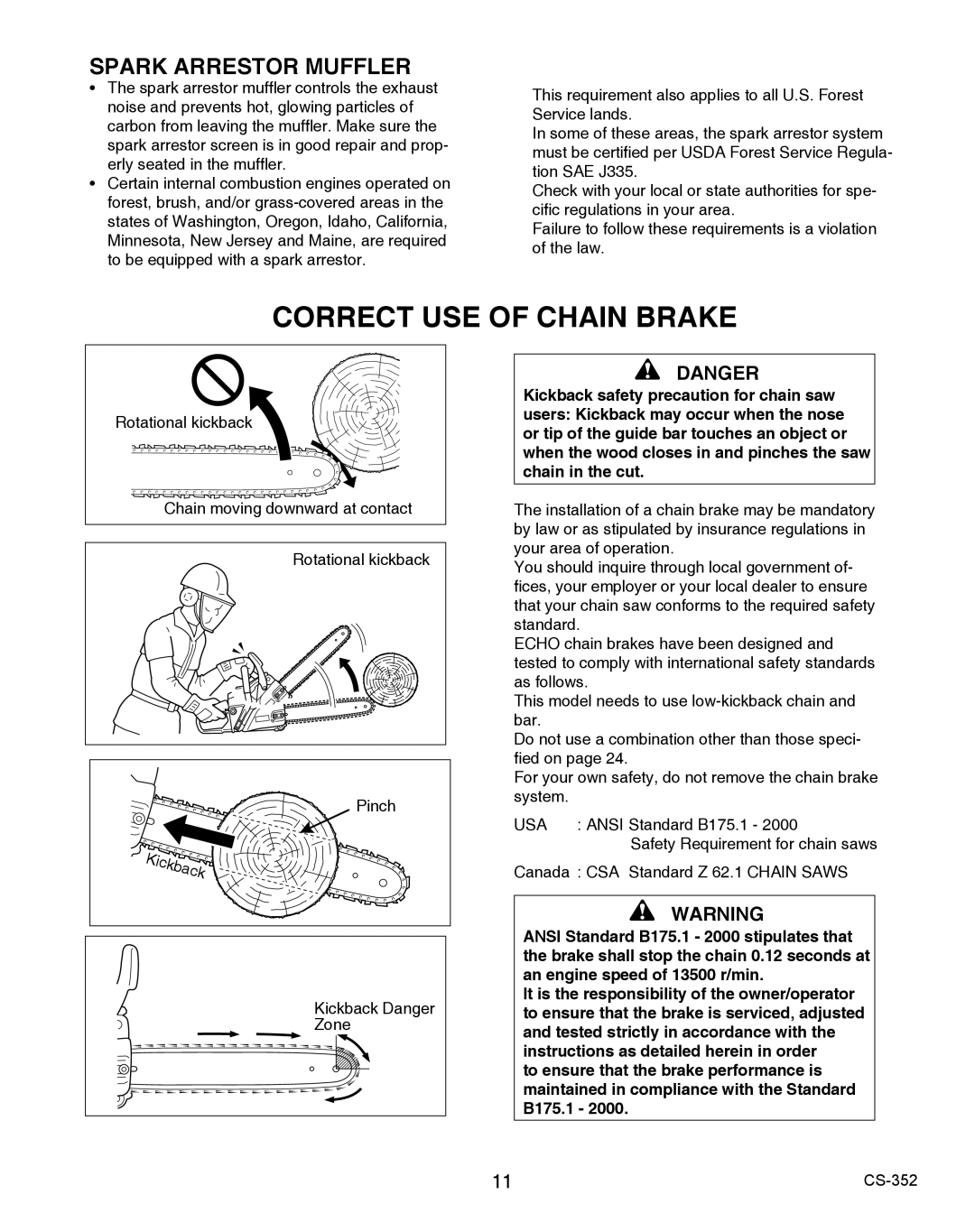

CORRECT USE OF CHAIN BRAKE

Rotational kickback

Chain moving downward at contact

Rotational kickback

Pinch |

Kickback Danger

Zone

DANGER

Kickback safety precaution for chain saw users: Kickback may occur when the nose or tip of the guide bar touches an object or when the wood closes in and pinches the saw chain in the cut.

The installation of a chain brake may be mandatory by law or as stipulated by insurance regulations in your area of operation.

You should inquire through local government of- fices, your employer or your local dealer to ensure that your chain saw conforms to the required safety standard.

ECHO chain brakes have been designed and tested to comply with international safety standards as follows.

This model needs to use

Do not use a combination other than those speci- fied on page 24.

For your own safety, do not remove the chain brake system.

USA | : ANSI Standard B175.1 - 2000 |

| Safety Requirement for chain saws |

Canada : CSA Standard Z 62.1 CHAIN SAWS

WARNING

ANSI Standard B175.1 - 2000 stipulates that the brake shall stop the chain 0.12 seconds at an engine speed of 13500 r/min.

It is the responsibility of the owner/operator to ensure that the brake is serviced, adjusted and tested strictly in accordance with the instructions as detailed herein in order

to ensure that the brake performance is maintained in compliance with the Standard B175.1 - 2000.

11 |