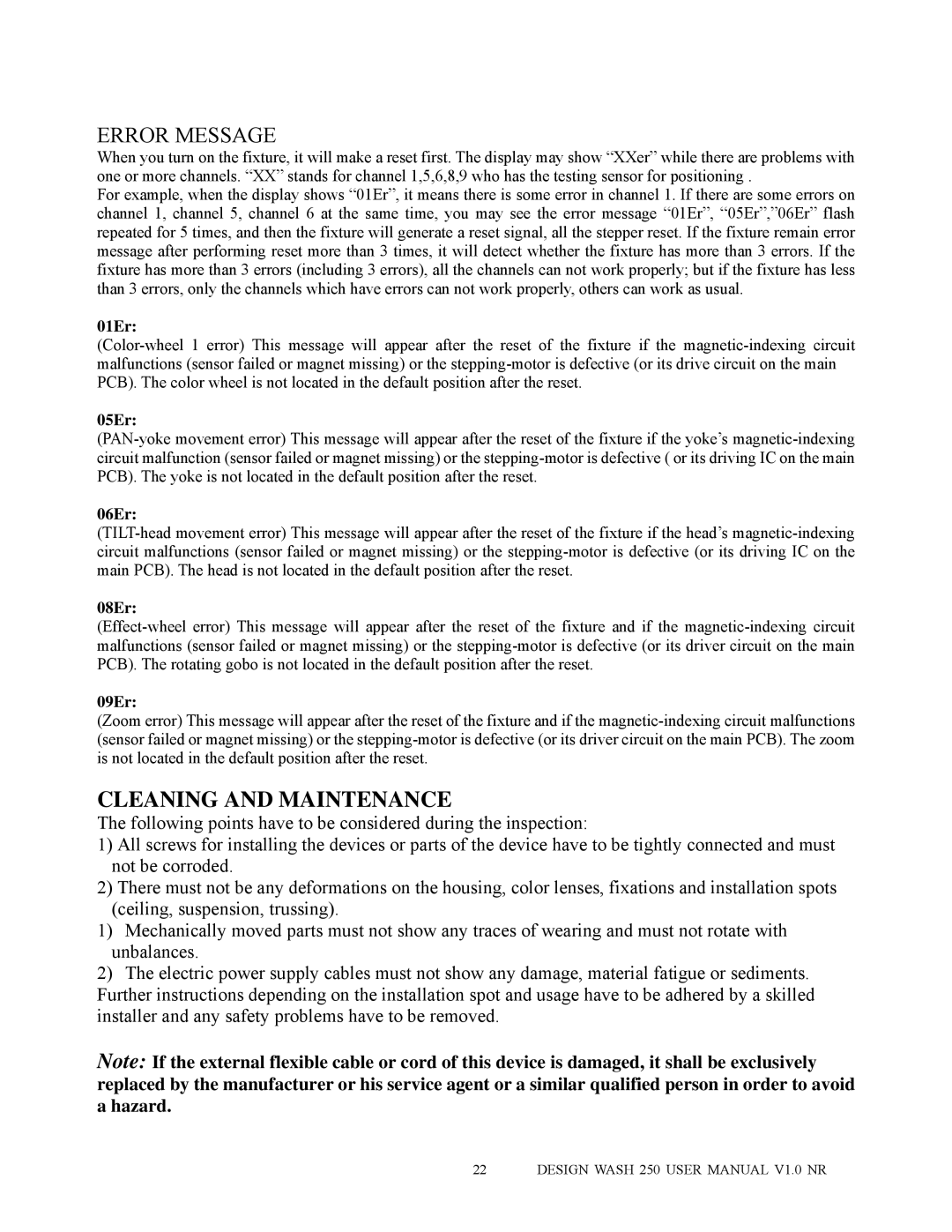

ERROR MESSAGE

When you turn on the fixture, it will make a reset first. The display may show “XXer” while there are problems with one or more channels. “XX” stands for channel 1,5,6,8,9 who has the testing sensor for positioning .

For example, when the display shows “01Er”, it means there is some error in channel 1. If there are some errors on channel 1, channel 5, channel 6 at the same time, you may see the error message “01Er”, “05Er”,”06Er” flash repeated for 5 times, and then the fixture will generate a reset signal, all the stepper reset. If the fixture remain error message after performing reset more than 3 times, it will detect whether the fixture has more than 3 errors. If the fixture has more than 3 errors (including 3 errors), all the channels can not work properly; but if the fixture has less than 3 errors, only the channels which have errors can not work properly, others can work as usual.

01Er:

05Er:

06Er:

08Er:

09Er:

(Zoom error) This message will appear after the reset of the fixture and if the

CLEANING AND MAINTENANCE

The following points have to be considered during the inspection:

1)All screws for installing the devices or parts of the device have to be tightly connected and must not be corroded.

2)There must not be any deformations on the housing, color lenses, fixations and installation spots (ceiling, suspension, trussing).

1)Mechanically moved parts must not show any traces of wearing and must not rotate with unbalances.

2)The electric power supply cables must not show any damage, material fatigue or sediments. Further instructions depending on the installation spot and usage have to be adhered by a skilled installer and any safety problems have to be removed.

Note: If the external flexible cable or cord of this device is damaged, it shall be exclusively replaced by the manufacturer or his service agent or a similar qualified person in order to avoid a hazard.

22 DESIGN WASH 250 USER MANUAL V1.0 NR