ERW20-1C specifications

The Elkay ERW20-1C is a high-performance drinking water fountain that exemplifies innovation and modern design in public water solutions. This unit is particularly appreciated in schools, parks, and office buildings for its functionality and user-friendly features. The ERW20-1C combines both a traditional water fountain and a bottle filling station, catering to the increasing demand for environmentally sustainable water sources.One of the main features of the Elkay ERW20-1C is its efficient dual-functionality. Users can enjoy fresh drinking water directly from the fountain or opt to fill reusable bottles, promoting sustainability and reducing single-use plastic waste. The fountain's advanced design incorporates a convenient push-button activation that allows for hands-free operation, making it an excellent choice for high-traffic areas.

The drinking water fountain utilizes a built-in filtration system that ensures the water is clean and free of contaminants. This feature is particularly important in public places where safety and quality are paramount. The filter is easily accessible for maintenance, making it simple to replace when necessary and ensuring that users receive the best quality drinking water.

Another noteworthy characteristic of the Elkay ERW20-1C is its robust construction. Made from durable stainless steel, the fountain is resistant to corrosion and is designed to withstand the wear and tear of daily use in busy environments. The sleek finish also provides an attractive aesthetic that blends well with various architectural styles.

The Elkay ERW20-1C is designed with sustainability in mind. It is equipped with environmental sensors that monitor usage and conserve energy, making it a wise choice for those looking to reduce their environmental footprint. Additionally, the fountain boasts a maintenance-free design, thanks to its advanced technology, which helps to minimize downtime and operational costs.

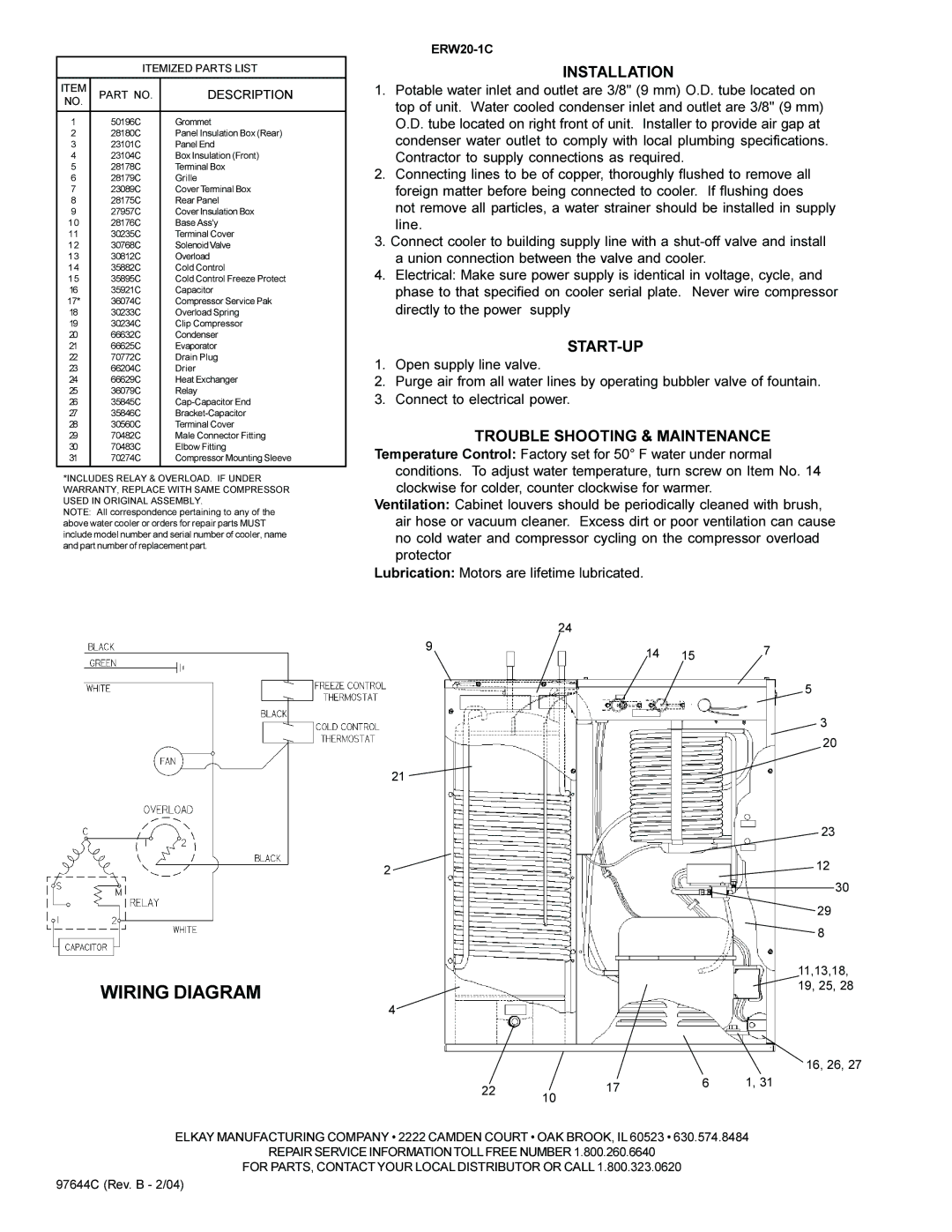

In terms of installation, the Elkay ERW20-1C is user-friendly and adaptable to various settings. Its compact design allows for easy integration into existing infrastructure, making it suitable for retrofitting older spaces or new construction projects.

Overall, the Elkay ERW20-1C stands out as a modern solution for hydration. With its dual functionality, advanced filtration, durable construction, and eco-friendly features, it effectively meets the needs of communities while promoting health and wellness. This innovative drinking water fountain is an ideal choice for anyone looking to provide accessible and clean drinking water in a stylish, sustainable manner.