Introduction

Thank you for choosing this kiln! We have designed it to give you many years of reliable service.

Please read this manual. It will help you gain the maximum enjoyment from your kiln. It will show you how to avoid damag- ing the kiln and will answer many questions. Your instruction packet also includes a separate digital controller manual. Please save both manuals.

Inspect the kiln. When you receive your kiln, check the carton for damage (crushed, holes, etc.). Check the kiln for both inte- rior and exterior damage. If the kiln is damaged, you can refuse the shipment and have it returned, or accept the shipment after having the driver note the damage on the Bill of Lading.

Check the Bill of Lading to insure that you received the correct number of packages. Note any shortages on the Bill of Lading, and have the driver sign the copy.

If there were no signs of visible kiln damage and you discover it after the driver has left, notify the shipper immediately.

Save the shipping carton. It was carefully designed to pro- vide maximum protection during shipping. Use the carton to take the kiln to seminars or on vacation, or to return the kiln to the factory for repairs.

Needless worries. Tremendous stresses are generated within the kiln. The ceramic fiber firing chamber actually ex- pands and contracts with each firing. Do not be concerned if small cracks appear in the fiber. This is normal. These are sur- face cracks that close tightly when the heated fiber expands. You may find a small pin hole in the center of the firing chamber. It is from the manufacturing process and will not affect the kiln’s performance.

The paint around the door will eventually discolor from heat. This, again, will not affect the kiln’s performance.

During firing, you will hear an intermittent, distinct clicking. This is the sound of the relay(s) sending power to the heating elements. Do not be concerned with this sound.

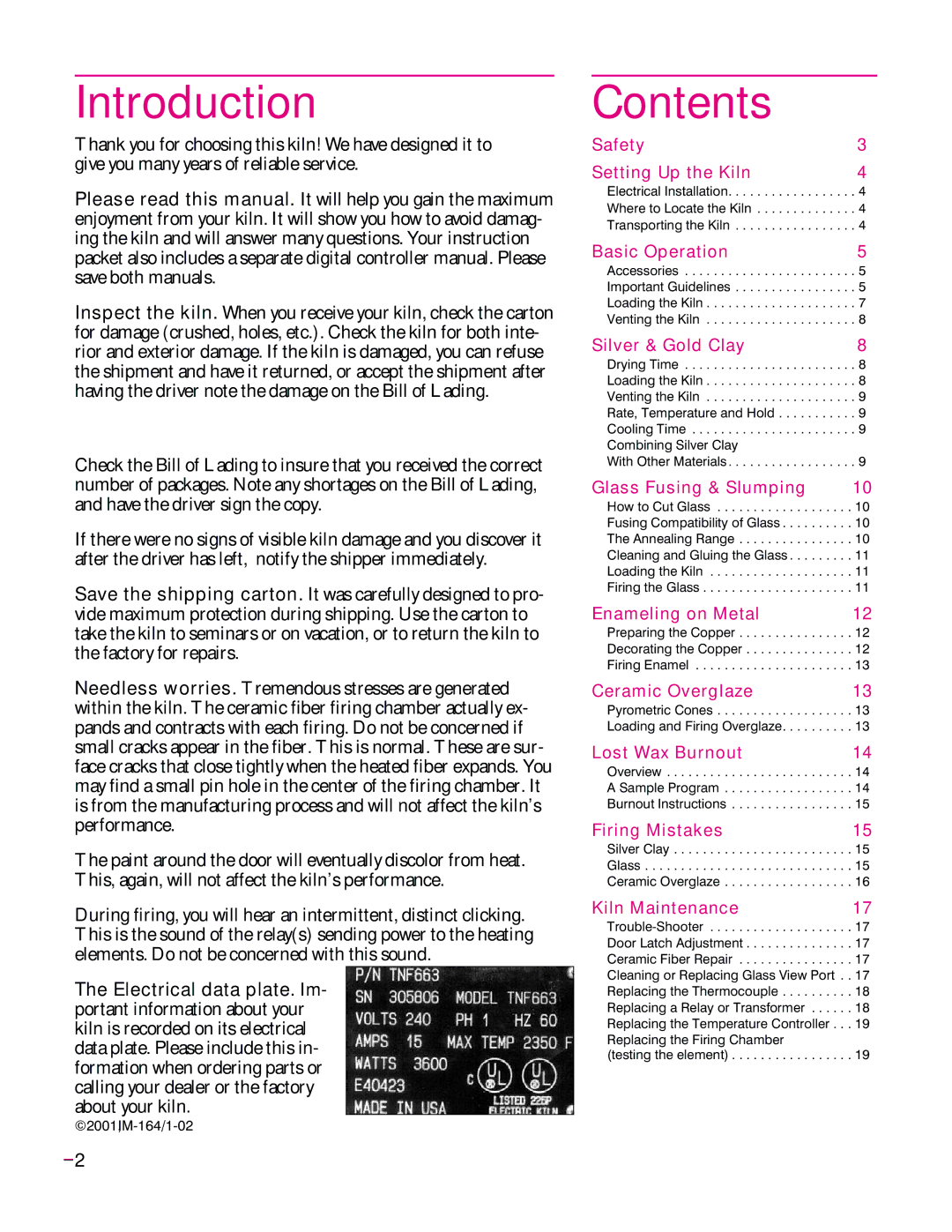

The Electrical data plate. Im-

portant information about your kiln is recorded on its electrical data plate. Please include this in- formation when ordering parts or calling your dealer or the factory about your kiln.

Contents

Safety | 3 |

Setting Up the Kiln | 4 |

Electrical Installation. . . . . . . . . . . . . . . . . . 4 Where to Locate the Kiln . . . . . . . . . . . . . . 4 Transporting the Kiln . . . . . . . . . . . . . . . . . 4

Basic Operation | 5 |

Accessories | 5 |

Important Guidelines | 5 |

Loading the Kiln | 7 |

Venting the Kiln | 8 |

Silver & Gold Clay | 8 |

Drying Time . . . . . . . . . . . . . . . . . . . . . . . . 8

Loading the Kiln . . . . . . . . . . . . . . . . . . . . . 8

Venting the Kiln . . . . . . . . . . . . . . . . . . . . . 9

Rate, Temperature and Hold . . . . . . . . . . . 9

Cooling Time . . . . . . . . . . . . . . . . . . . . . . . 9

Combining Silver Clay

With Other Materials . . . . . . . . . . . . . . . . . . 9

Glass Fusing & Slumping | 10 |

How to Cut Glass . . . . . . . . . . . . . . . . . . . 10 Fusing Compatibility of Glass . . . . . . . . . . 10 The Annealing Range . . . . . . . . . . . . . . . . 10 Cleaning and Gluing the Glass . . . . . . . . . 11 Loading the Kiln . . . . . . . . . . . . . . . . . . . . 11 Firing the Glass . . . . . . . . . . . . . . . . . . . . . 11

Enameling on Metal | 12 |

Preparing the Copper | 12 |

Decorating the Copper | 12 |

Firing Enamel | 13 |

Ceramic Overglaze | 13 |

Pyrometric Cones | 13 |

Loading and Firing Overglaze | 13 |

Lost Wax Burnout | 14 |

Overview | 14 |

A Sample Program | 14 |

Burnout Instructions | 15 |

Firing Mistakes | 15 |

Silver Clay | 15 |

Glass | 15 |

Ceramic Overglaze | 16 |

Kiln Maintenance | 17 |

Replacing the Firing Chamber

(testing the element) . . . . . . . . . . . . . . . . . 19

2