agent to keep the grains of enamel in place. Allow the enamel to dry completely before firing.

Firing Enamel

1Heat the kiln to 1450°F/787°C for most enameling. Use a Single Segment. (Please see your digital con- troller instruction manual.)

| Rate | Temp. |

|

Segment | °F/°C | °F/°C | Hold |

Ceramic Overglaze

Pyrometric Cones

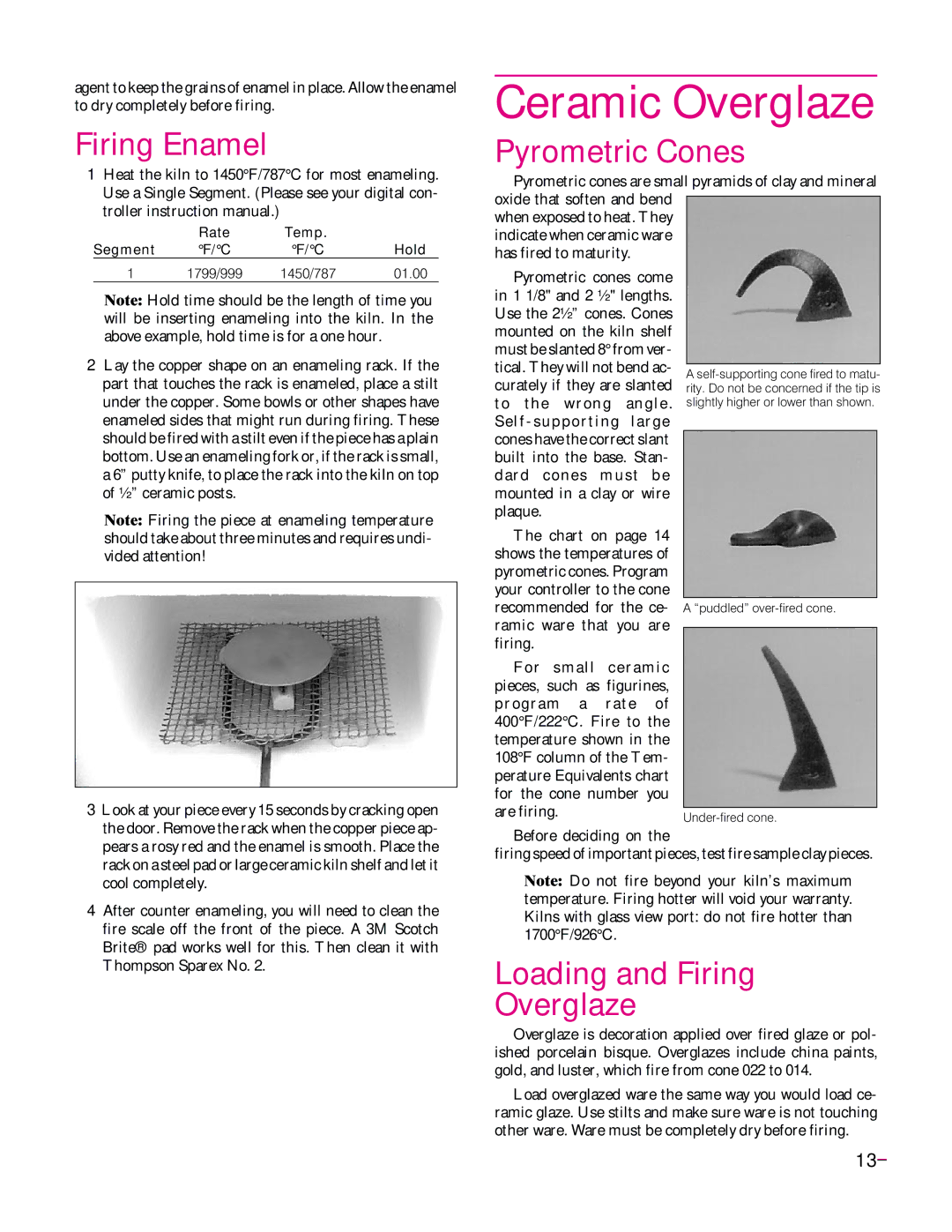

Pyrometric cones are small pyramids of clay and mineral oxide that soften and bend

when exposed to heat. They indicate when ceramic ware has fired to maturity.

1 | 1799/999 | 1450/787 | 01.00 |

Note: Hold time should be the length of time you will be inserting enameling into the kiln. In the above example, hold time is for a one hour.

2Lay the copper shape on an enameling rack. If the part that touches the rack is enameled, place a stilt under the copper. Some bowls or other shapes have enameled sides that might run during firing. These should be fired with a stilt even if the piece has a plain bottom. Use an enameling fork or, if the rack is small, a 6” putty knife, to place the rack into the kiln on top of ½” ceramic posts.

Note: Firing the piece at enameling temperature should take about three minutes and requires undi- vided attention!

3 Look at your piece every 15 seconds by cracking open |

Pyrometric cones come in 1 1/8" and 2 ½" lengths. Use the 2½” cones. Cones mounted on the kiln shelf must be slanted 8° from ver- tical. They will not bend ac- curately if they are slanted to the wrong angle.

The chart on page 14 shows the temperatures of pyrometric cones. Program your controller to the cone recommended for the ce- ramic ware that you are firing.

For small ceramic pieces, such as figurines, program a rate of 400°F/222°C. Fire to the temperature shown in the 108°F column of the Tem- perature Equivalents chart for the cone number you are firing.

A

A “puddled”

the door. Remove the rack when the copper piece ap- |

pears a rosy red and the enamel is smooth. Place the |

rack on a steel pad or large ceramic kiln shelf and let it |

cool completely. |

4 After counter enameling, you will need to clean the |

fire scale off the front of the piece. A 3M Scotch |

Brite® pad works well for this. Then clean it with |

Thompson Sparex No. 2. |

Before deciding on the

firing speed of important pieces, test fire sample clay pieces.

Note: Do not fire beyond your kiln’s maximum temperature. Firing hotter will void your warranty. Kilns with glass view port: do not fire hotter than 1700°F/926°C.

Loading and Firing

Overglaze

Overglaze is decoration applied over fired glaze or pol- ished porcelain bisque. Overglazes include china paints, gold, and luster, which fire from cone 022 to 014.

Load overglazed ware the same way you would load ce- ramic glaze. Use stilts and make sure ware is not touching other ware. Ware must be completely dry before firing.

13