18

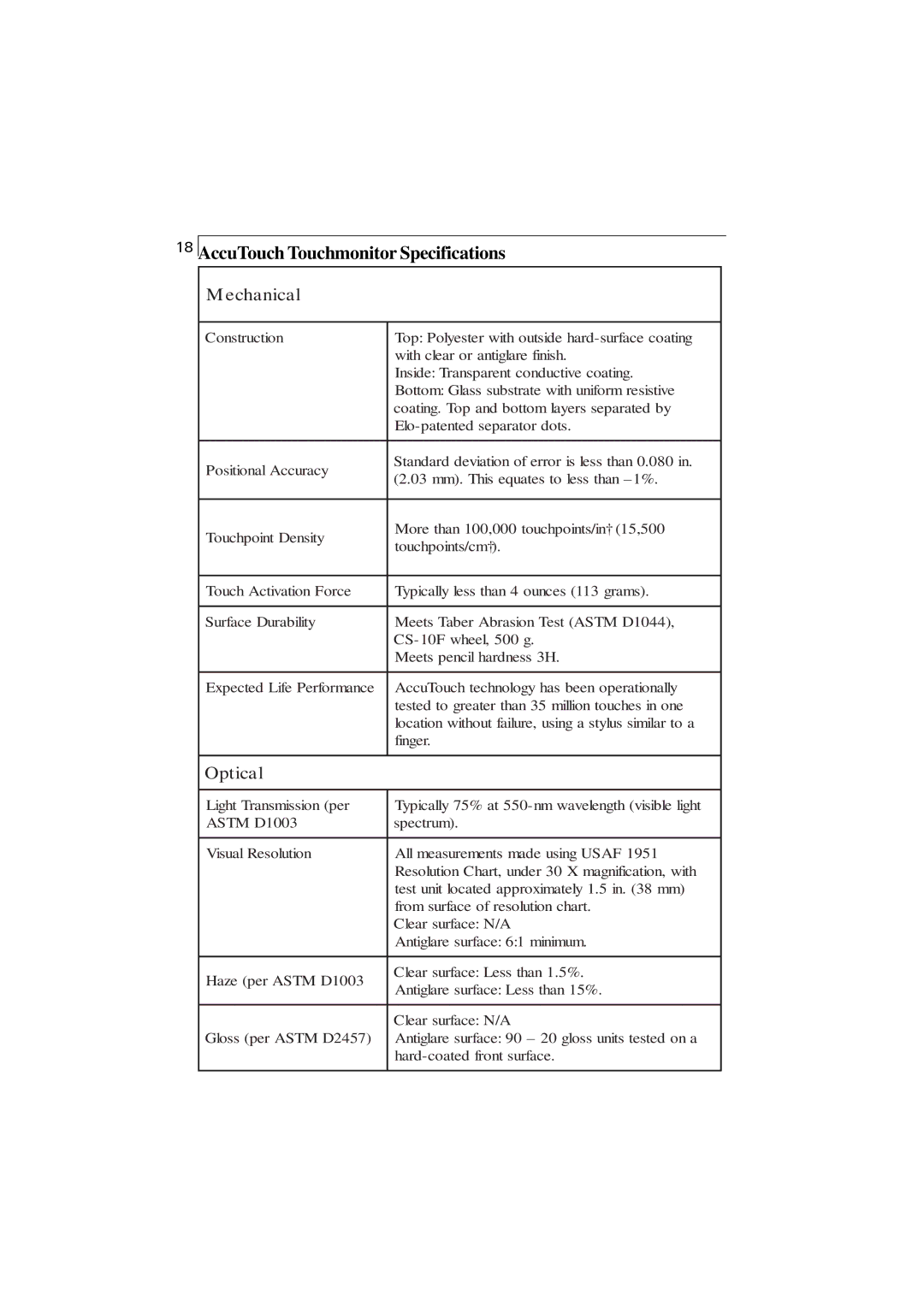

AccuTouch Touchmonitor Specifications

M echanical

Construction | Top: Polyester with outside | |

| with clear or antiglare finish. | |

| Inside: Transparent conductive coating. | |

| Bottom: Glass substrate with uniform resistive | |

| coating. Top and bottom layers separated by | |

| ||

|

| |

Positional Accuracy | Standard deviation of error is less than 0.080 in. | |

(2.03 mm). This equates to less than | ||

| ||

|

| |

Touchpoint Density | More than 100,000 touchpoints/in† (15,500 | |

touchpoints/cm†). | ||

| ||

|

| |

Touch Activation Force | Typically less than 4 ounces (113 grams). | |

|

| |

Surface Durability | Meets Taber Abrasion Test (ASTM D1044), | |

| ||

| Meets pencil hardness 3H. | |

|

| |

Expected Life Performance | AccuTouch technology has been operationally | |

| tested to greater than 35 million touches in one | |

| location without failure, using a stylus similar to a | |

| finger. | |

|

| |

Optical |

| |

|

| |

Light Transmission (per | Typically 75% at | |

ASTM D1003 | spectrum). | |

|

| |

Visual Resolution | All measurements made using USAF 1951 | |

| Resolution Chart, under 30 X magnification, with | |

| test unit located approximately 1.5 in. (38 mm) | |

| from surface of resolution chart. | |

| Clear surface: N/A | |

| Antiglare surface: 6:1 minimum. | |

|

| |

Haze (per ASTM D1003 | Clear surface: Less than 1.5%. | |

Antiglare surface: Less than 15%. | ||

| ||

|

| |

| Clear surface: N/A | |

Gloss (per ASTM D2457) | Antiglare surface: 90 – 20 gloss units tested on a | |

| ||

|

|