BOOK 0958-B

9.If the controller contains any options that require external wiring, follow the wiring instructions in the instruction sheet supplied with the option.

10.If remote operator control wiring and/or signal wiring is required, connect the controller as shown in the appropriate connection diagram (Figures 3 through 18). Figures 3 through 11 show operator control connections, and Figures 12 through 18 show signal connections.

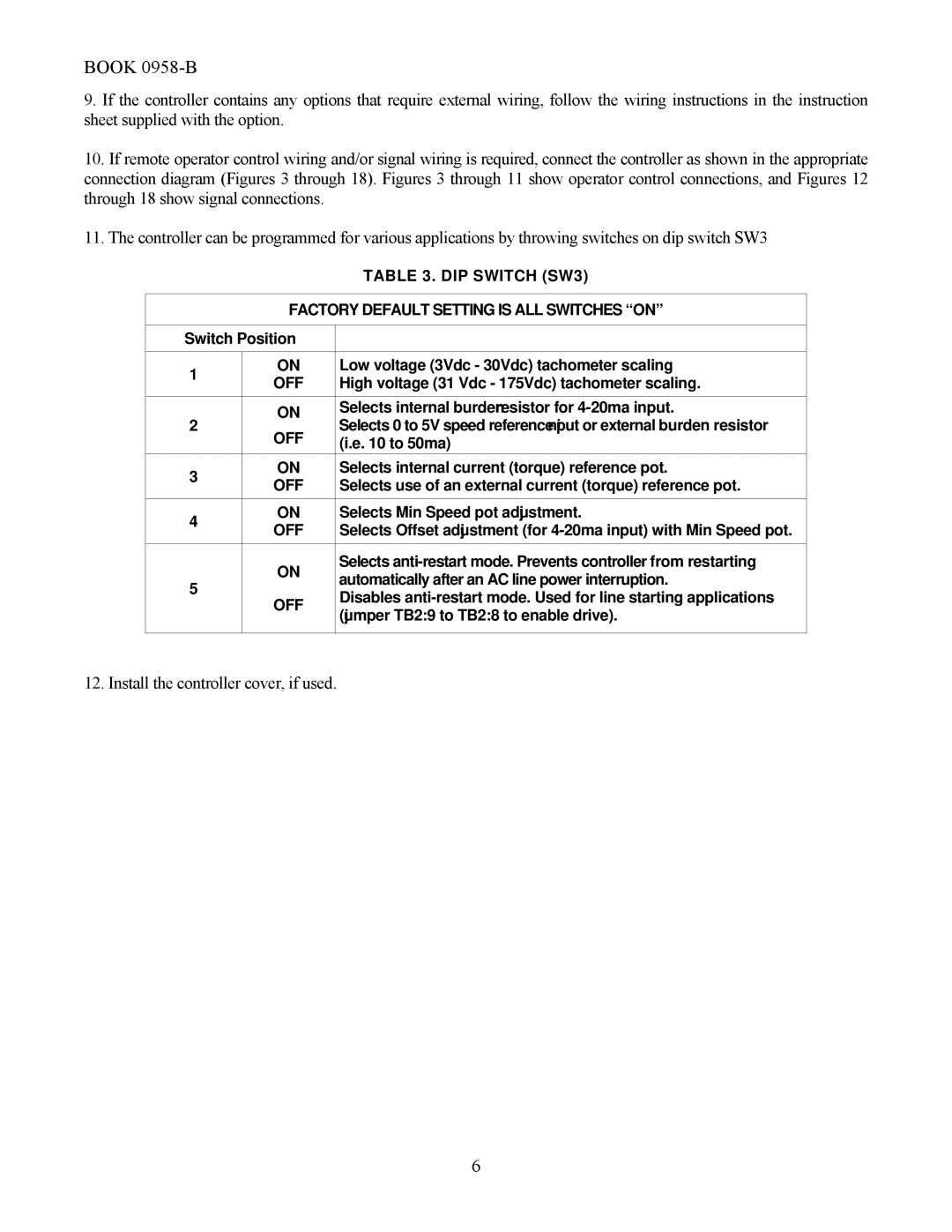

11.The controller can be programmed for various applications by throwing switches on dip switch SW3

TABLE 3. DIP SWITCH (SW3)

FACTORY DEFAULT SETTING IS ALL SWITCHES “ON”

Switch Position |

| ||

1 | ON | Low voltage (3Vdc - 30Vdc) tachometer scaling | |

OFF | High voltage (31 Vdc - 175Vdc) tachometer scaling. | ||

| |||

2 | ON | Selects internal burden resistor for | |

OFF | Selects 0 to 5V speed reference input or external burden resistor | ||

| (i.e. 10 to 50ma) | ||

3 | ON | Selects internal current (torque) reference pot. | |

OFF | Selects use of an external current (torque) reference pot. | ||

| |||

4 | ON | Selects Min Speed pot adjustment. | |

OFF | Selects Offset adjustment (for | ||

| |||

| ON | Selects | |

5 | automatically after an AC line power interruption. | ||

| |||

OFF | Disables | ||

| |||

| (jumper TB2:9 to TB2:8 to enable drive). | ||

|

| ||

|

|

| |

12. Install the controller cover, if used.

6