BP7408 44" & 52" Curva 1/12/10 8:52 AM Page 6

![]()

![]() 6. Remove and retain the wire connectors

6. Remove and retain the wire connectors ![]() from the white and blue wires.

from the white and blue wires.

![]()

![]() 7. Connect the wire wire from the ceiling fan to the white wire of the light kit plate (Figure 3). Connect the blue wire from the ceiling fan to the black wire of the

7. Connect the wire wire from the ceiling fan to the white wire of the light kit plate (Figure 3). Connect the blue wire from the ceiling fan to the black wire of the ![]()

![]() light kit plate. Use wire connectors (previously removed) to make connections.

light kit plate. Use wire connectors (previously removed) to make connections.

![]()

![]() 8. Remove one of the three screws in the lower housing and loosen the remaining two screws (Figure 3).

8. Remove one of the three screws in the lower housing and loosen the remaining two screws (Figure 3).

11.Carefully turn the partially assembled ceiling fan right side up and place the fan securely into the packing styrofoam in preparation for final assembly.

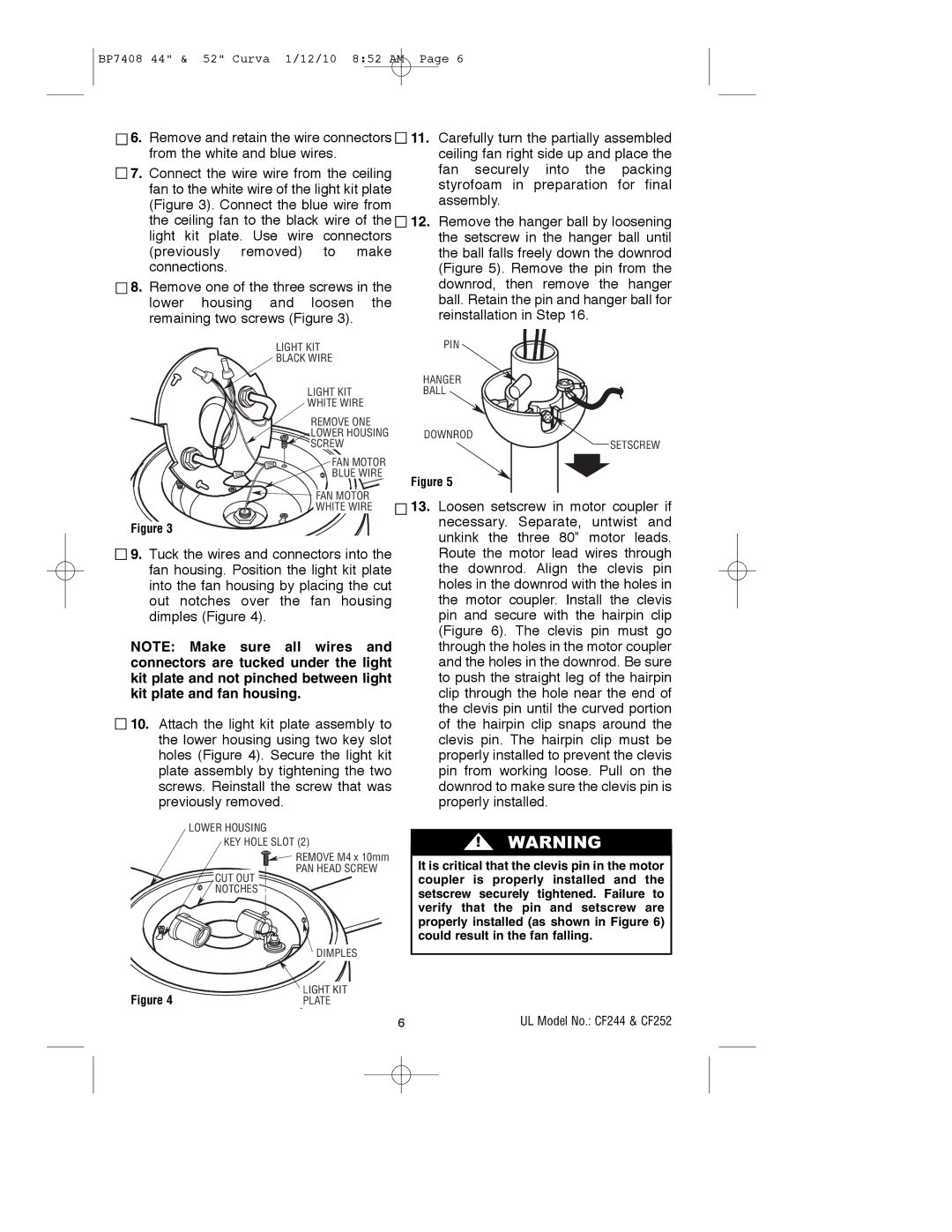

12.Remove the hanger ball by loosening the setscrew in the hanger ball until the ball falls freely down the downrod (Figure 5). Remove the pin from the downrod, then remove the hanger ball. Retain the pin and hanger ball for reinstallation in Step 16.

LIGHT KIT | PIN |

BLACK WIRE |

|

| HANGER |

LIGHT KIT | BALL |

WHITE WIRE |

|

REMOVE ONE

LOWER HOUSING

SCREW

FAN MOTOR

BLUE WIRE

![]() FAN MOTOR

FAN MOTOR

WHITE WIRE

Figure 3

![]()

![]() 9. Tuck the wires and connectors into the fan housing. Position the light kit plate into the fan housing by placing the cut out notches over the fan housing dimples (Figure 4).

9. Tuck the wires and connectors into the fan housing. Position the light kit plate into the fan housing by placing the cut out notches over the fan housing dimples (Figure 4).

NOTE: Make sure all wires and connectors are tucked under the light kit plate and not pinched between light kit plate and fan housing.

![]()

![]() 10. Attach the light kit plate assembly to the lower housing using two key slot holes (Figure 4). Secure the light kit plate assembly by tightening the two screws. Reinstall the screw that was previously removed.

10. Attach the light kit plate assembly to the lower housing using two key slot holes (Figure 4). Secure the light kit plate assembly by tightening the two screws. Reinstall the screw that was previously removed.

DOWNROD

SETSCREW

Figure 5

![]()

![]() 13. Loosen setscrew in motor coupler if necessary. Separate, untwist and unkink the three 80” motor leads. Route the motor lead wires through the downrod. Align the clevis pin holes in the downrod with the holes in the motor coupler. Install the clevis pin and secure with the hairpin clip (Figure 6). The clevis pin must go through the holes in the motor coupler and the holes in the downrod. Be sure to push the straight leg of the hairpin clip through the hole near the end of the clevis pin until the curved portion of the hairpin clip snaps around the clevis pin. The hairpin clip must be properly installed to prevent the clevis pin from working loose. Pull on the downrod to make sure the clevis pin is properly installed.

13. Loosen setscrew in motor coupler if necessary. Separate, untwist and unkink the three 80” motor leads. Route the motor lead wires through the downrod. Align the clevis pin holes in the downrod with the holes in the motor coupler. Install the clevis pin and secure with the hairpin clip (Figure 6). The clevis pin must go through the holes in the motor coupler and the holes in the downrod. Be sure to push the straight leg of the hairpin clip through the hole near the end of the clevis pin until the curved portion of the hairpin clip snaps around the clevis pin. The hairpin clip must be properly installed to prevent the clevis pin from working loose. Pull on the downrod to make sure the clevis pin is properly installed.

LOWER HOUSING

KEY HOLE SLOT (2)

| REMOVE M4 x 10mm |

| PAN HEAD SCREW |

| CUT OUT |

| NOTCHES |

| DIMPLES |

Figure 4 | LIGHT KIT |

PLATE |

6

!![]() WARNING

WARNING

It is critical that the clevis pin in the motor coupler is properly installed and the setscrew securely tightened. Failure to verify that the pin and setscrew are properly installed (as shown in Figure 6) could result in the fan falling.