2.3 Switch Settings in MCU200 Series

(i)Gain switch(and potentiometer): See section 3.

(ii)Frequency selection

This slide switch is labelled “FREQ” and is located between the sensor terminal block E2, and the Aux input terminals. This selects the operating frequency of the MCU200 oscillator, which is either 3.7MHz (switch in the 'up' position) or 1 MHz, (switch to the down position). The

| 1MHz sensors | 3.7 MHz sensors |

|

|

|

| 30*S, 31*S, 32*S, 33*S | 36*S, 40*S, 42*S, 43*S, |

| 35*S, 37*S, 38*S, 39*S, | 44*S |

| HL*S, HD*S. | 601S, 621S. |

|

|

|

Fig. 6 Sensor frequencies |

| |

Where any sensor is built to operate at non standard frequency, it will have the suffix M1 or M3 at the end of the type number.

Mobrey sludge sensors type 433 and 448 with the suffix M1, built after S/No 9001, can operate at both 1MHz and 3.7 MHz. The MCU201 selection switch determines the operating frequency.

(iii) Cable check option selection

This slide switch is located directly above the sensor terminal block E2. It is labelled “Cable Check” and the ex factory setting is “OUT” with the slide switch to the right.

By sliding this switch to the left, the cable check circuitry is brought into action. This circuitry monitors the continuity of the screens of the two coaxial cables attached to the sensors: normally these are linked at the sensor to the metal body of the fitting (or to each other in the case of non metallic sensors). If this continuity is broken, the “FAULT” LED will illuminate giving an indication that the sensor cable is damaged, and the MCU200 will give the “ALARM” output relay state.

Note: OSC means sensor oscillating, E means relay energised, NE means

Colour code: |

|

|

|

Brown | 1 | Yellow | 4 |

Red | 2 | Green | 5 |

Orange3 |

| Blue | 6 |

NOTE: The construction of Hisens sensors type HL* and HD* and gap sensors types 601S, 621S prevents the use of this cable check system. The separated nature of the sensor pairs type 442S or 448S usually makes this cable check unreliable.

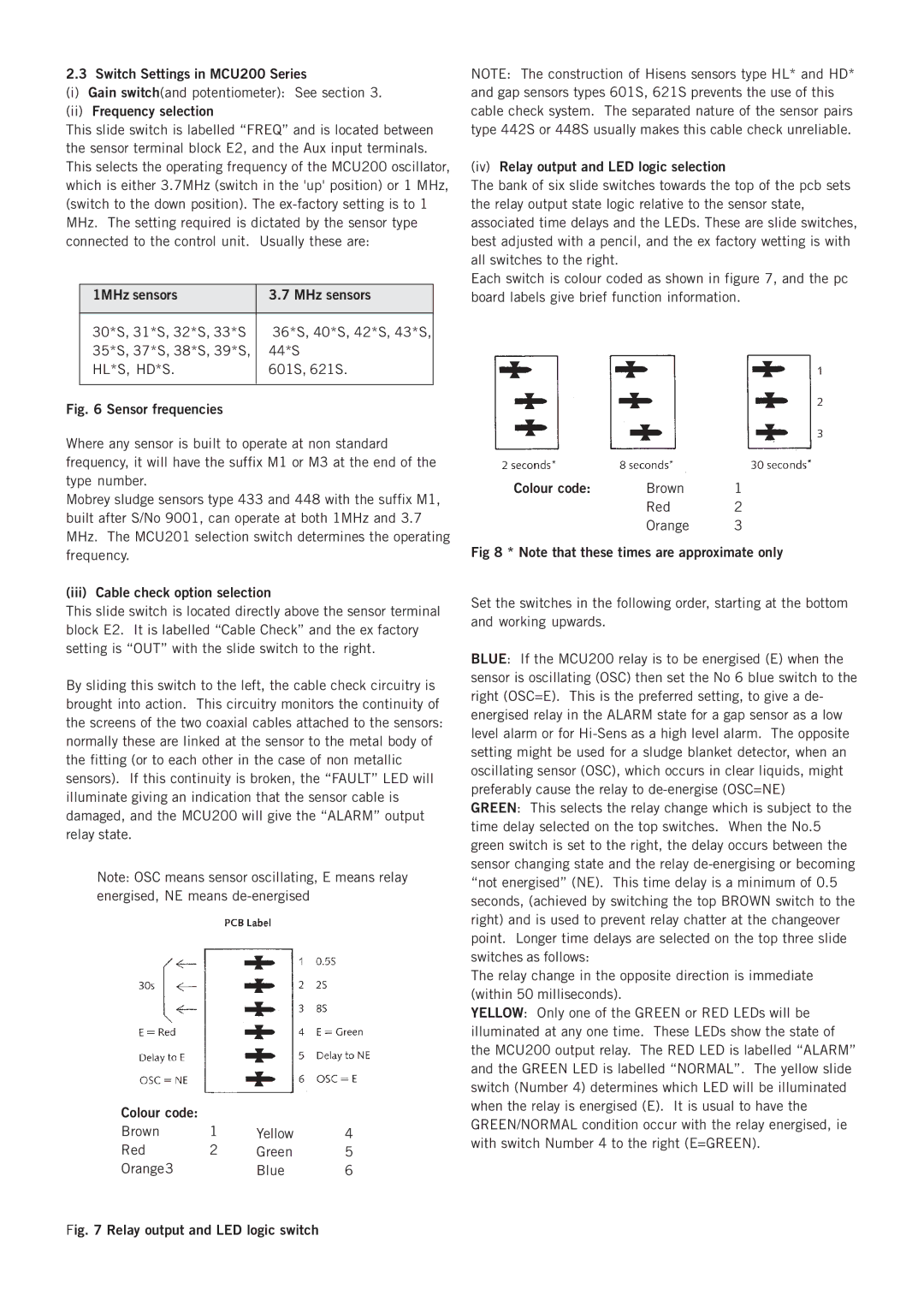

(iv)Relay output and LED logic selection

The bank of six slide switches towards the top of the pcb sets the relay output state logic relative to the sensor state, associated time delays and the LEDs. These are slide switches, best adjusted with a pencil, and the ex factory wetting is with all switches to the right.

Each switch is colour coded as shown in figure 7, and the pc board labels give brief function information.

Colour code: | Brown | 1 |

| Red | 2 |

| Orange | 3 |

Fig 8 * Note that these times are approximate only

Set the switches in the following order, starting at the bottom and working upwards.

BLUE: If the MCU200 relay is to be energised (E) when the sensor is oscillating (OSC) then set the No 6 blue switch to the right (OSC=E). This is the preferred setting, to give a de- energised relay in the ALARM state for a gap sensor as a low level alarm or for

GREEN: This selects the relay change which is subject to the time delay selected on the top switches. When the No.5 green switch is set to the right, the delay occurs between the sensor changing state and the relay

The relay change in the opposite direction is immediate (within 50 milliseconds).

YELLOW: Only one of the GREEN or RED LEDs will be illuminated at any one time. These LEDs show the state of the MCU200 output relay. The RED LED is labelled “ALARM” and the GREEN LED is labelled “NORMAL”. The yellow slide switch (Number 4) determines which LED will be illuminated when the relay is energised (E). It is usual to have the GREEN/NORMAL condition occur with the relay energised, ie with switch Number 4 to the right (E=GREEN).