3.4 Interface Detection

3.4.1.Suspended Solids blanket sludge discharge detection

The Mobrey MCU200 control unit can be used in conjunction with a 433S sensor to provide sludge blanket level detection in a settling tank, facilitating the control of automatic desludging. Similarly, in conjunction with a Mobrey sludge pipe using a pair of 488S sensors, the MCU200 can control the end of desludge cycle when thin solids are discharged. Figure 13 shows the operation of the sensor. In a clear liquid the ultrasonic signal is carried across the gap and the sensor “oscillates”. In a dirty liquid - one containing high levels of suspended solids - the signal cannot cross the gap and the oscillation ceases. (Note that this is the same condition that occurs when the sensor is in air.) The Mobrey 433 sensor is normally suspended in the settling tank itself.

Fig. 13 Type 433 sensor for suspended solids blanket alarm

An alternative sensor type is Mobrey sludge pipe, installed on the sludge discharge line from the tank. In this application it is essential to install the pipe section close to the tank discharge, below the bottom of the tank. This maintains the hydraulic pressure on the sludge to prevent release of dissolved gases. Any such air entrained will give a false “thick sludge” indication.

Fig. 14 Sludge discharge control

The application of fig 14 shows a control valve opening on a timed basis to discharge the sludge. Once sludge is flowing along the line, the control valve can be closed by the MCU200 when sludge of low density is detected. The gain pot gives adjustment of the % solids level at which the output relay trips, increasing sludge density for clockwise rotation.

Settled sludge discharge control

(i)Reduce time delays (see fig 8) to make adjustment easier. Set frequence of operation to 1 MHz (see fig 5) if the sensor will operate at this frequency.

(ii)With sensor or pipe in relatively clean water (supernatant) set gain switch to “LO” and reduce gain pot (see fig 5) until the LED changes. Note this point on the pot as the “zero suspended solids” switch point.

(iii)For a 1 MHz sensor on a 150mm or 200mm ID pipeline or sensor gap, working on primary sewage sludges, each division on the potentiometer increase above this zero switch point represents approximately 1% suspended solids.

Increase the pot to the desired level, remembering a 2 division overlap between “LO” and HI” gain ranges.

Check the setting in practice by taking a sludge sample at the switch point, and adjust as necessary. Increasing the gain pot makes the switch point occur at a higher suspended solids level.

(iv)For different diameter pipelines or sensor gaps, of dimensions Dmm, each division represents (180¸D) % solids approximately.

(v)In a 3.7 MHz system, on a 150mm gap sensor each division represents 0.25% solids: for sensor gaps Dmm the divisions are (38¸D) % solids typically.

Overflow alarm or fine solids detection

(i)Set frequency to 3.7 MHz if sensor is suitable. This improves sensitivity.

(ii)Reduce time delays and locate “zero” position as above.

(iii)Assume gain pot adjustment is (90¸D) % solids per division increase to set initial switch point.

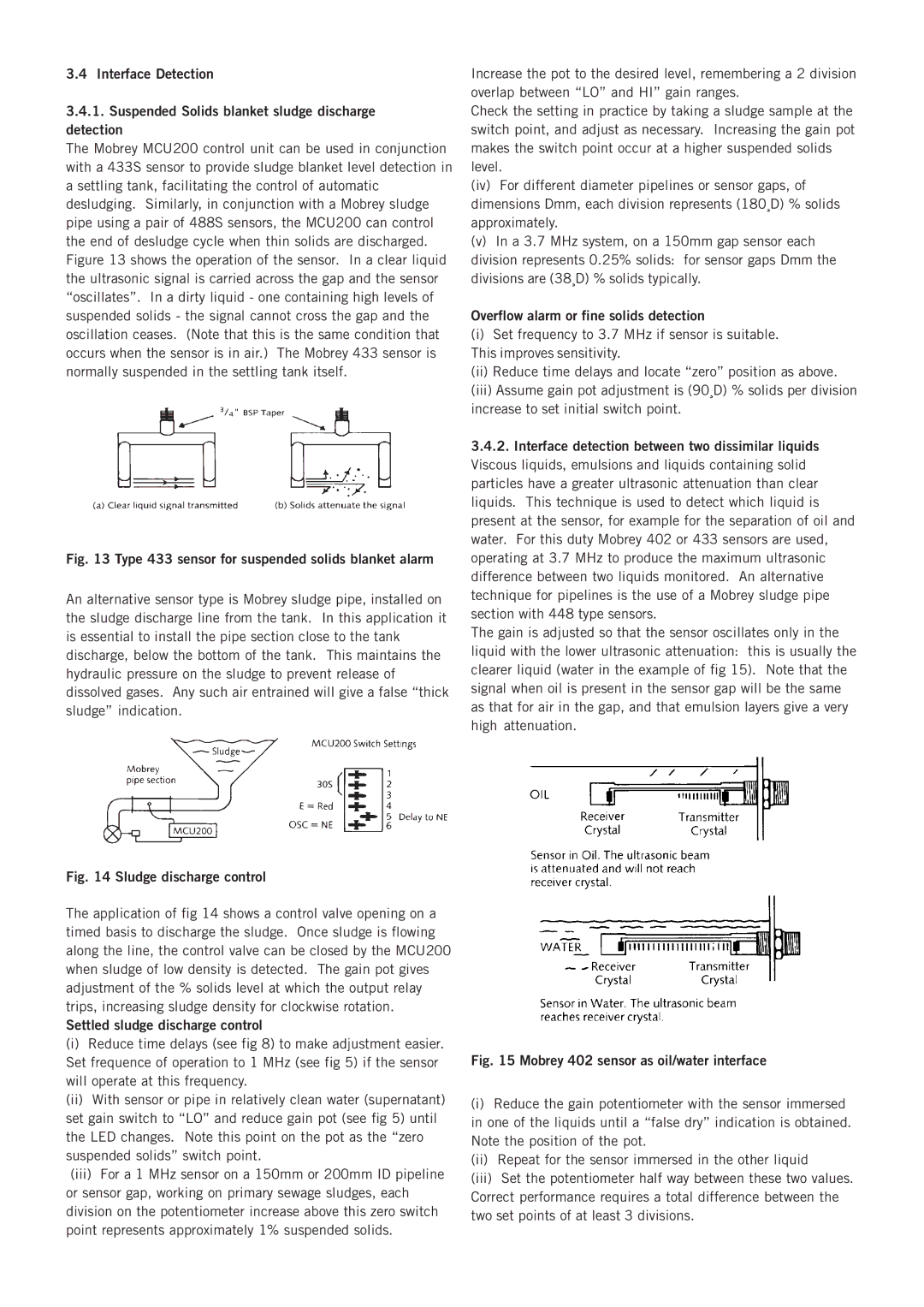

3.4.2.Interface detection between two dissimilar liquids Viscous liquids, emulsions and liquids containing solid particles have a greater ultrasonic attenuation than clear liquids. This technique is used to detect which liquid is present at the sensor, for example for the separation of oil and water. For this duty Mobrey 402 or 433 sensors are used, operating at 3.7 MHz to produce the maximum ultrasonic difference between two liquids monitored. An alternative technique for pipelines is the use of a Mobrey sludge pipe section with 448 type sensors.

The gain is adjusted so that the sensor oscillates only in the liquid with the lower ultrasonic attenuation: this is usually the clearer liquid (water in the example of fig 15). Note that the signal when oil is present in the sensor gap will be the same as that for air in the gap, and that emulsion layers give a very high attenuation.

Fig. 15 Mobrey 402 sensor as oil/water interface

(i)Reduce the gain potentiometer with the sensor immersed in one of the liquids until a “false dry” indication is obtained. Note the position of the pot.

(ii)Repeat for the sensor immersed in the other liquid

(iii)Set the potentiometer half way between these two values. Correct performance requires a total difference between the two set points of at least 3 divisions.