3.Applications

3.1 Gain adjustment

Correct adjustment of the gain (HI/LO switch and potentiometer) is essential for proper operation of any ultrasonic sensor system. This adjusts the gain of the feedback amplifier in the control unit, which produces oscillation of the sensor when the coupling between the ultrasonic crystals is sufficient. Therefore the higher the gain setting, the lower the coupling needed to produce an oscillating sensor.

The universal control unit of the MCU200 operates with many sensors, so the correct setting for the particular sensor and application should be found on site by experiment, if possible. This will take account of particular site conditions like RF coupling between extension cables, which can affect the maximum allowed gain.

Other liquid characteristics, such as presence of suspended solids, or air bubbles, can mean that for reliable operation the MCU200 gain must be set as high as possible, to overcome future solids build up, but at least one potentiometer division below the maximum allowed level, to ensure temperature and component ageing stability. With Hisens sensors, condensation on the sensor may be overcome by increasing the gain as high as possible. With sludge blanket sensors, the gain adjustment changes the density of sludge at which the system will switch, increased gain giving increased solids levels.

The particular procedures outlined below for gain adjustments give the mid point gain settings, which may need to be adjusted to meet specific site/sensor future requirements as indicated above.

3.2 Level Alarm

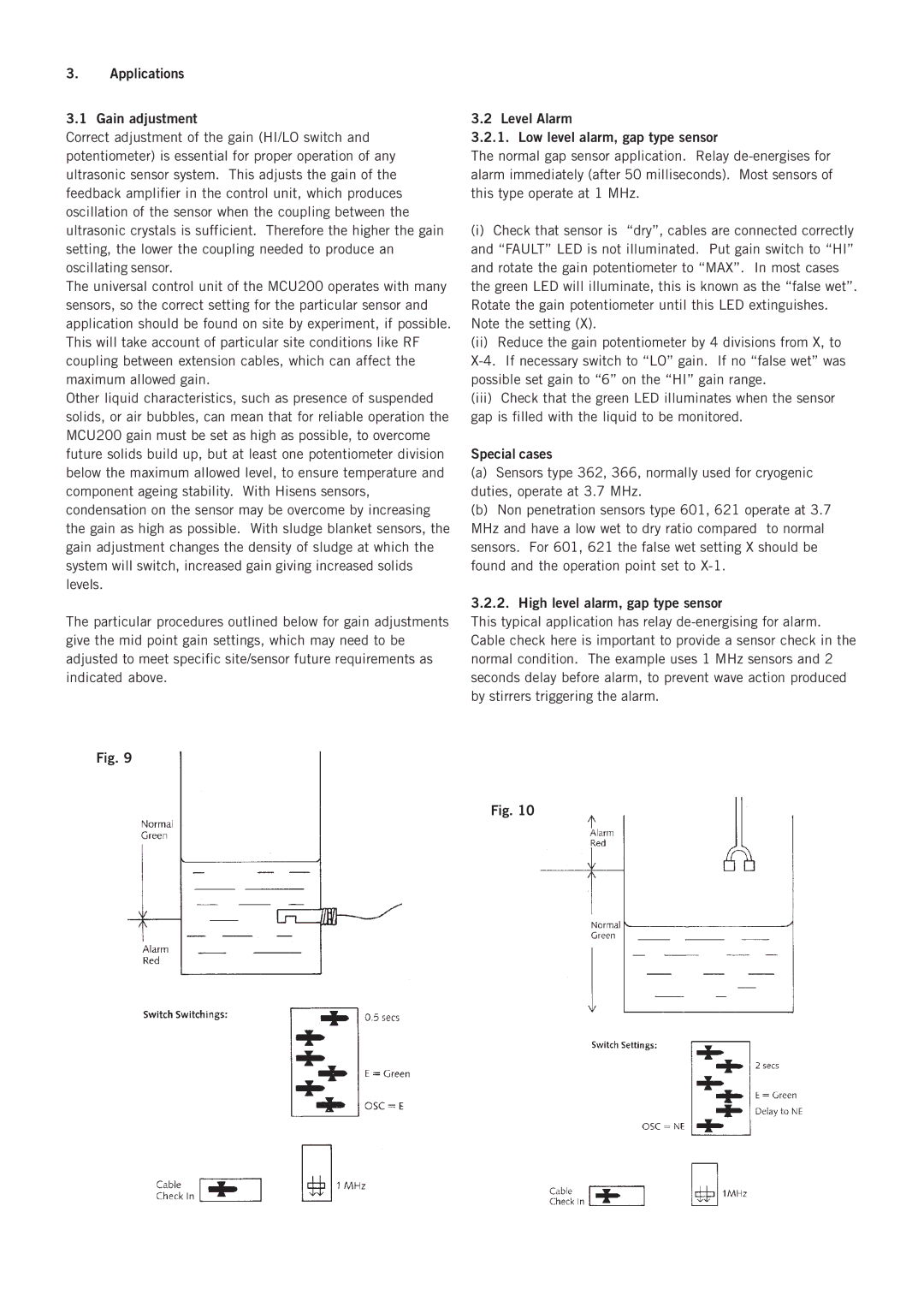

3.2.1. Low level alarm, gap type sensor

The normal gap sensor application. Relay

(i)Check that sensor is “dry”, cables are connected correctly and “FAULT” LED is not illuminated. Put gain switch to “HI” and rotate the gain potentiometer to “MAX”. In most cases the green LED will illuminate, this is known as the “false wet”. Rotate the gain potentiometer until this LED extinguishes. Note the setting (X).

(ii)Reduce the gain potentiometer by 4 divisions from X, to

(iii)Check that the green LED illuminates when the sensor gap is filled with the liquid to be monitored.

Special cases

(a)Sensors type 362, 366, normally used for cryogenic duties, operate at 3.7 MHz.

(b)Non penetration sensors type 601, 621 operate at 3.7 MHz and have a low wet to dry ratio compared to normal sensors. For 601, 621 the false wet setting X should be found and the operation point set to

3.2.2. High level alarm, gap type sensor

This typical application has relay

Fig. 9

Fig. 10