Instruction Sheet

PN

Model 410VP

Four-electrode Conductivity Sensor

For additional information, please refer to the Instruction Manuals CD shipped with this product, or visit our website at www/rosemountanalytical.

![]() CAUTION

CAUTION

SENSOR/PROCESS APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible with process composition and operating conditions. Application compatibility is entirely the responsibility of the user.

CAUTION

WARNING

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and the process temperature is lowered to a safe level!

SENSOR SPECIFICATIONS

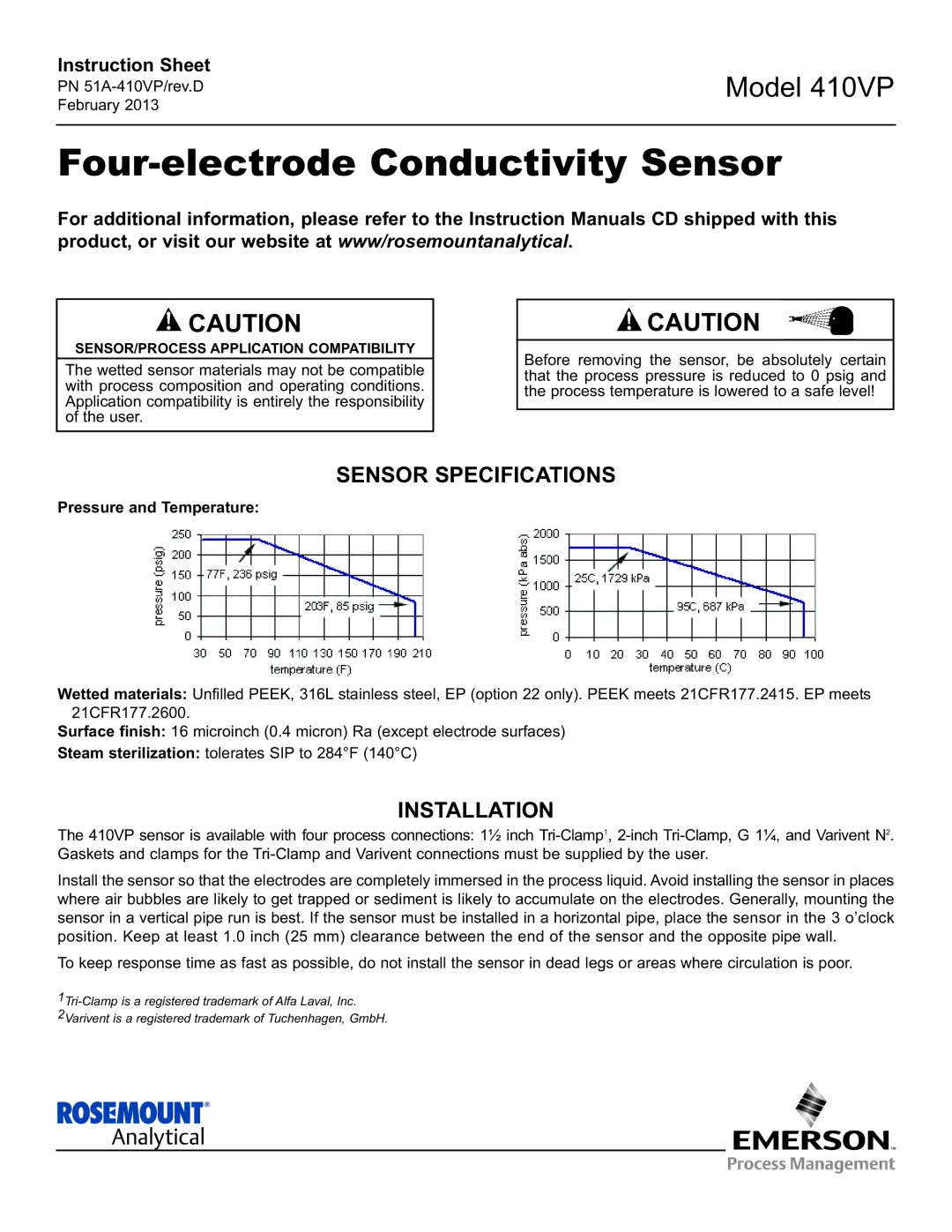

Pressure and Temperature:

Wetted materials: Unfilled PEEK, 316L stainless steel, EP (option 22 only). PEEK meets 21CFR177.2415. EP meets 21CFR177.2600.

Surface finish: 16 microinch (0.4 micron) Ra (except electrode surfaces)

Steam sterilization: tolerates SIP to 284°F (140°C)

INSTALLATION

The 410VP sensor is available with four process connections: 1½ inch

Install the sensor so that the electrodes are completely immersed in the process liquid. Avoid installing the sensor in places where air bubbles are likely to get trapped or sediment is likely to accumulate on the electrodes. Generally, mounting the sensor in a vertical pipe run is best. If the sensor must be installed in a horizontal pipe, place the sensor in the 3 o’clock position. Keep at least 1.0 inch (25 mm) clearance between the end of the sensor and the opposite pipe wall.

To keep response time as fast as possible, do not install the sensor in dead legs or areas where circulation is poor.

2Varivent is a registered trademark of Tuchenhagen, GmbH.