MODEL 410VP | CALIBRATION |

SETUP AND CALIBRATION

The sensor is calibrated at the factory and does not require initial

After a period of service, the sensor may require calibration. The sensor can be calibrated against a solution having known conductivity or against a referee meter and sensor. If using a standard solution, choose one having conductivity greater than 500 uS/cm. Do not use standard solutions having conductivity less than 100 uS/cm. They are susceptible to contamination by atmospheric carbon dioxide, which can alter the conductivity by a variable amount as great as 1.2 uS/cm (at 25°C). Calibration changes the cell constant only, not the calibration factor. If you wish to change the calibration factor, consult the factory. For more information about calibrating contacting conductivity sensors see application sheet ADS

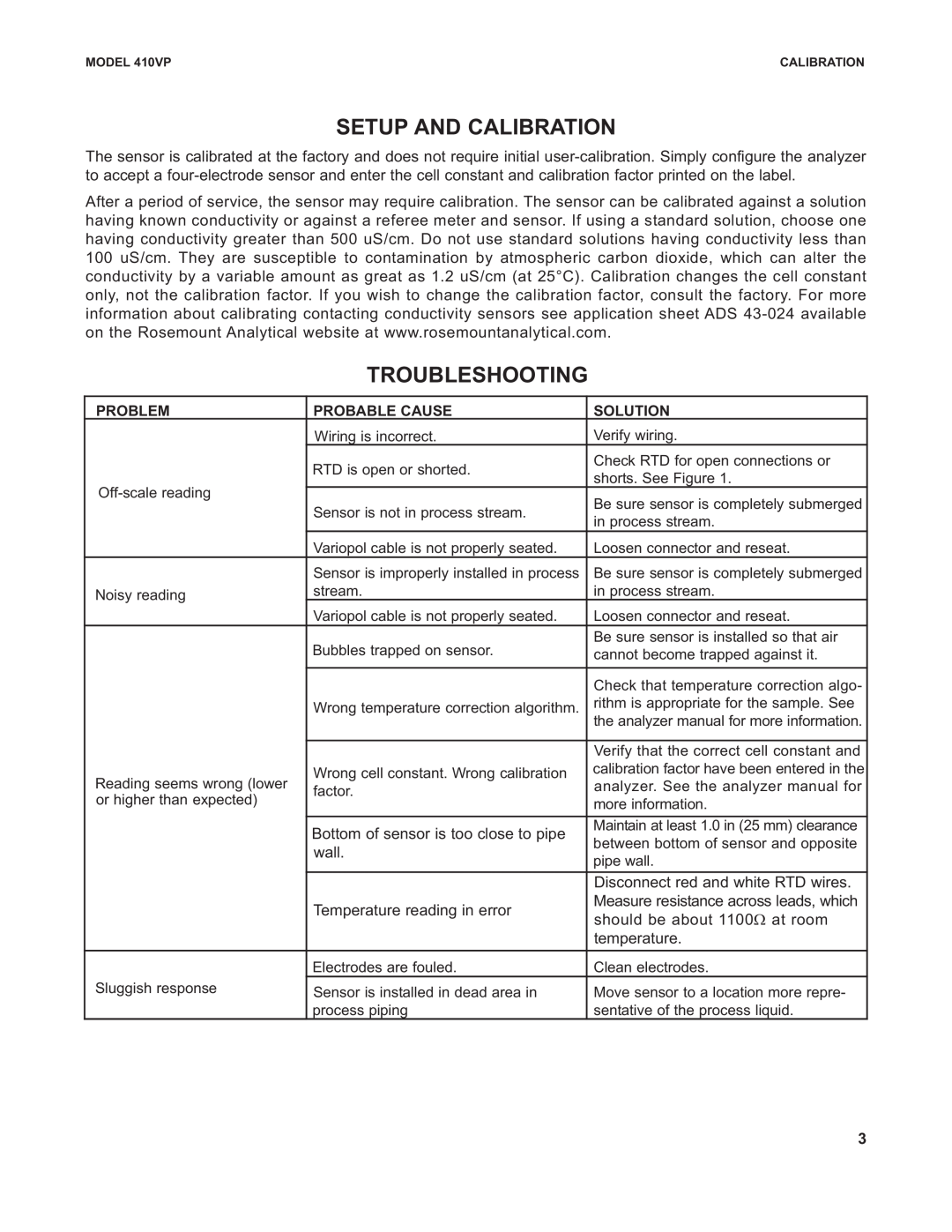

TROUBLESHOOTING

PROBLEM | PROBABLE CAUSE | SOLUTION | |

| Wiring is incorrect. | Verify wiring. | |

| RTD is open or shorted. | Check RTD for open connections or | |

| shorts. See Figure 1. | ||

|

| ||

Sensor is not in process stream. | Be sure sensor is completely submerged | ||

| |||

| in process stream. | ||

|

| ||

| Variopol cable is not properly seated. | Loosen connector and reseat. | |

| Sensor is improperly installed in process | Be sure sensor is completely submerged | |

Noisy reading | stream. | in process stream. | |

| Variopol cable is not properly seated. | Loosen connector and reseat. | |

| Bubbles trapped on sensor. | Be sure sensor is installed so that air | |

| cannot become trapped against it. | ||

|

| ||

|

|

| |

|

| Check that temperature correction algo- | |

| Wrong temperature correction algorithm. | rithm is appropriate for the sample. See | |

|

| the analyzer manual for more information. | |

|

|

| |

|

| Verify that the correct cell constant and | |

| Wrong cell constant. Wrong calibration | calibration factor have been entered in the | |

Reading seems wrong (lower | analyzer. See the analyzer manual for | ||

factor. | |||

or higher than expected) | more information. | ||

| |||

|

| ||

|

|

| |

| Bottom of sensor is too close to pipe | Maintain at least 1.0 in (25 mm) clearance | |

| between bottom of sensor and opposite | ||

| wall. | ||

| pipe wall. | ||

|

| ||

|

|

| |

|

| Disconnect red and white RTD wires. | |

| Temperature reading in error | Measure resistance across leads, which | |

| should be about 1100Ω at room | ||

|

| ||

|

| temperature. | |

|

|

| |

| Electrodes are fouled. | Clean electrodes. | |

Sluggish response | Sensor is installed in dead area in | Move sensor to a location more repre- | |

| |||

| process piping | sentative of the process liquid. |

3