ASSEMBLING

AND ADJUSTING

THE TOOL RESTS

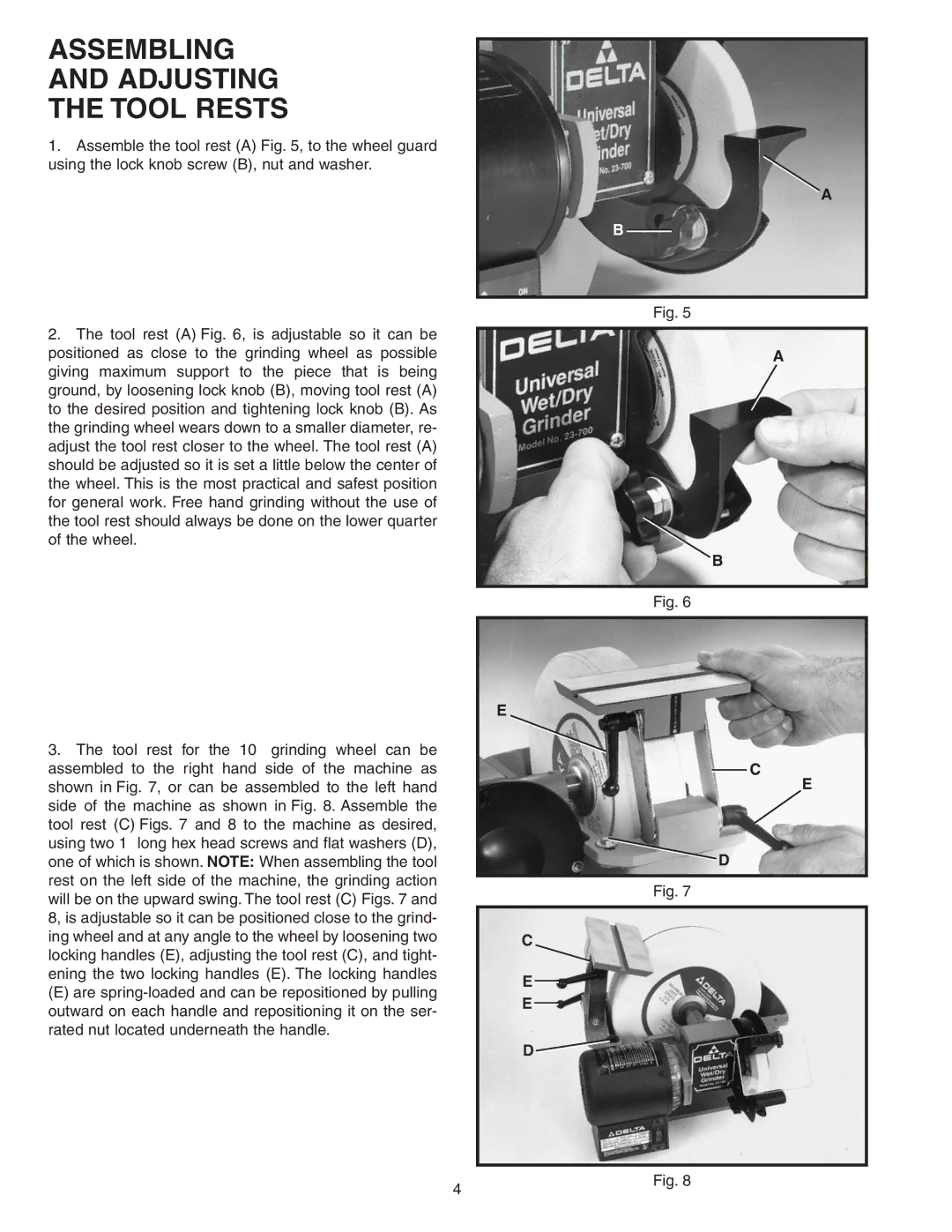

1.Assemble the tool rest (A) Fig. 5, to the wheel guard using the lock knob screw (B), nut and washer.

2.The tool rest (A) Fig. 6, is adjustable so it can be positioned as close to the grinding wheel as possible giving maximum support to the piece that is being ground, by loosening lock knob (B), moving tool rest (A) to the desired position and tightening lock knob (B). As the grinding wheel wears down to a smaller diameter, re- adjust the tool rest closer to the wheel. The tool rest (A) should be adjusted so it is set a little below the center of the wheel. This is the most practical and safest position for general work. Free hand grinding without the use of the tool rest should always be done on the lower quarter of the wheel.

3.The tool rest for the 10 grinding wheel can be assembled to the right hand side of the machine as shown in Fig. 7, or can be assembled to the left hand side of the machine as shown in Fig. 8. Assemble the tool rest (C) Figs. 7 and 8 to the machine as desired, using two 1 long hex head screws and flat washers (D), one of which is shown. NOTE: When assembling the tool rest on the left side of the machine, the grinding action will be on the upward swing. The tool rest (C) Figs. 7 and 8, is adjustable so it can be positioned close to the grind- ing wheel and at any angle to the wheel by loosening two locking handles (E), adjusting the tool rest (C), and tight- ening the two locking handles (E). The locking handles

(E) are

A

B

Fig. 5

A

B

Fig. 6

E

C

E

D

Fig. 7

C

E

E

D ![]()

4

Fig. 8