ADJUSTING

SPARK DEFLECTOR

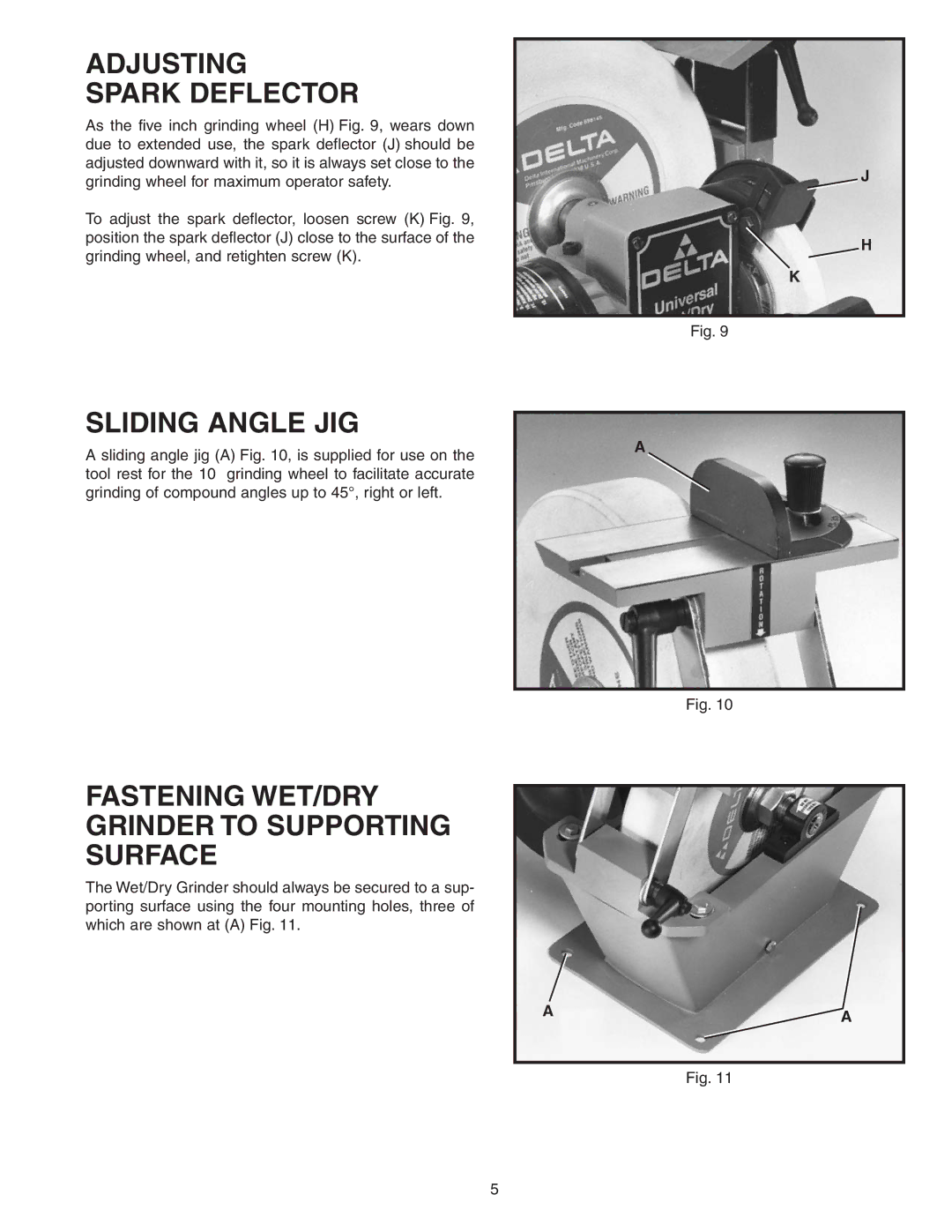

As the five inch grinding wheel (H) Fig. 9, wears down due to extended use, the spark deflector (J) should be adjusted downward with it, so it is always set close to the grinding wheel for maximum operator safety.

To adjust the spark deflector, loosen screw (K) Fig. 9, position the spark deflector (J) close to the surface of the grinding wheel, and retighten screw (K).

J

H

K

Fig. 9

SLIDING ANGLE JIG

A sliding angle jig (A) Fig. 10, is supplied for use on the tool rest for the 10 grinding wheel to facilitate accurate grinding of compound angles up to 45°, right or left.

A

Fig. 10

FASTENING WET/DRY

GRINDER TO SUPPORTING

SURFACE

The Wet/Dry Grinder should always be secured to a sup- porting surface using the four mounting holes, three of which are shown at (A) Fig. 11.

AA

Fig. 11

5