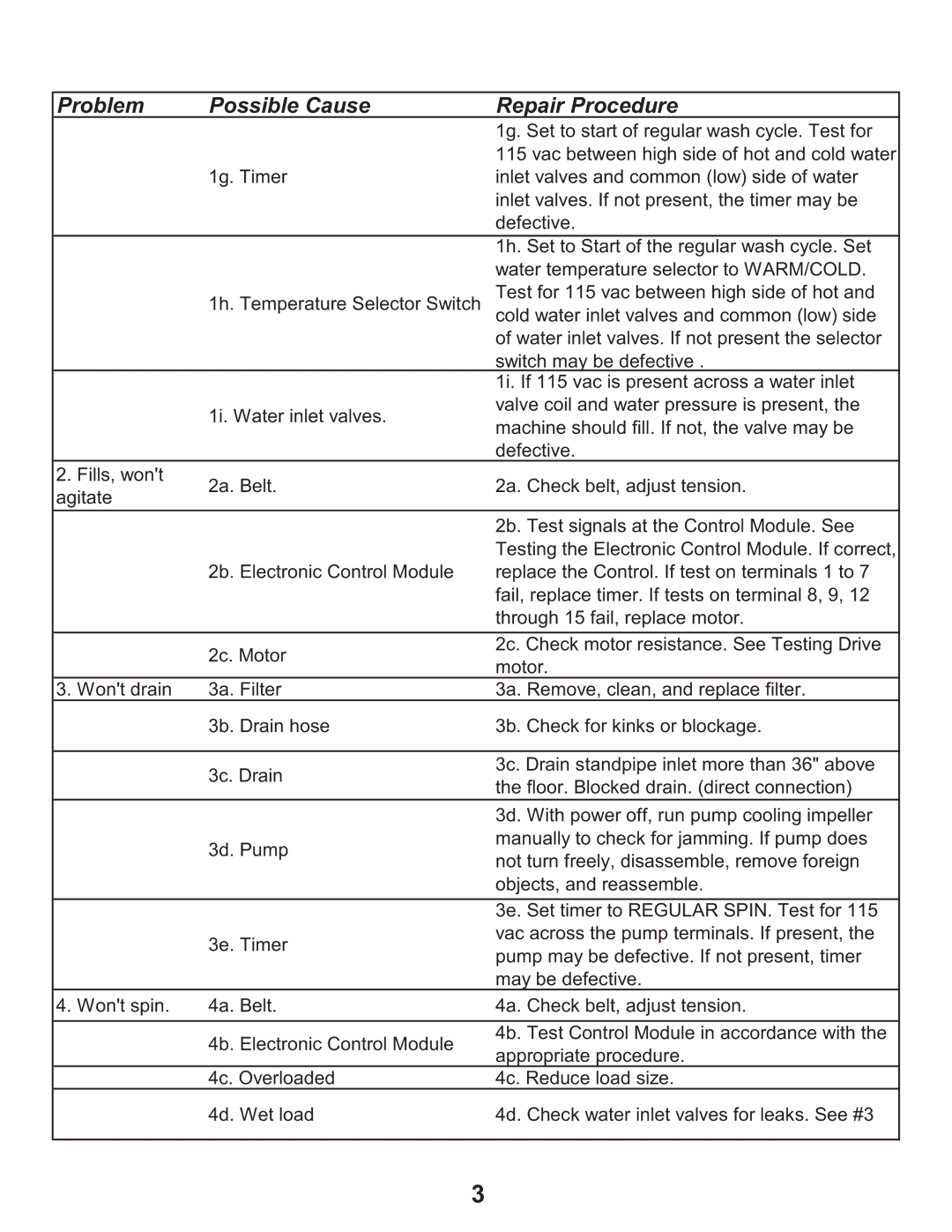

Problem | Possible Cause | Repair Procedure | |

|

| 1g. Set to start of regular wash cycle. Test for | |

|

| 115 vac between high side of hot and cold water | |

| 1g. Timer | inlet valves and common (low) side of water | |

|

| inlet valves. If not present, the timer may be | |

|

| defective. | |

|

| 1h. Set to Start of the regular wash cycle. Set | |

|

| water temperature selector to WARM/COLD. | |

| 1h. Temperature Selector Switch | Test for 115 vac between high side of hot and | |

|

| cold water inlet valves and common (low) side | |

|

| of water inlet valves. If not present the selector | |

|

| switch may be defective . | |

|

| 1i. If 115 vac is present across a water inlet | |

| 1i. Water inlet valves. | valve coil and water pressure is present, the | |

| machine should fill. If not, the valve may be | ||

|

| ||

|

| defective. | |

2. Fills, won't | 2a. Belt. | 2a. Check belt, adjust tension. | |

agitate | |||

|

| ||

|

|

| |

|

| 2b. Test signals at the Control Module. See | |

|

| Testing the Electronic Control Module. If correct, | |

| 2b. Electronic Control Module | replace the Control. If test on terminals 1 to 7 | |

|

| fail, replace timer. If tests on terminal 8, 9, 12 | |

|

| through 15 fail, replace motor. | |

|

|

| |

| 2c. Motor | 2c. Check motor resistance. See Testing Drive | |

| motor. | ||

|

| ||

3. Won't drain | 3a. Filter | 3a. Remove, clean, and replace filter. | |

| 3b. Drain hose | 3b. Check for kinks or blockage. | |

|

|

| |

| 3c. Drain | 3c. Drain standpipe inlet more than 36" above | |

| the floor. Blocked drain. (direct connection) | ||

|

| ||

|

| 3d. With power off, run pump cooling impeller | |

| 3d. Pump | manually to check for jamming. If pump does | |

| not turn freely, disassemble, remove foreign | ||

|

| ||

|

| objects, and reassemble. | |

|

|

| |

|

| 3e. Set timer to REGULAR SPIN. Test for 115 | |

| 3e. Timer | vac across the pump terminals. If present, the | |

| pump may be defective. If not present, timer | ||

|

| ||

|

| may be defective. | |

4. Won't spin. | 4a. Belt. | 4a. Check belt, adjust tension. | |

|

|

| |

| 4b. Electronic Control Module | 4b. Test Control Module in accordance with the | |

| appropriate procedure. | ||

|

| ||

| 4c. Overloaded | 4c. Reduce load size. | |

| 4d. Wet load | 4d. Check water inlet valves for leaks. See #3 | |

|

|

|

3