| |

|

|

ICOM FREQUENCY ADJUSTMENT

First, check the frequency to determine if any adjustment is required. The frequency measurement requires equipment with an absolute accuracy which is 5 to 10 times better than the tolerance to be maintained. When performing frequency measurement, the entire radio should be as near as possible to an ambient temperature of 26.5°C (79.8°F).

MASTR II ICOMs should be reset only when the measured frequency error exceeds the following limits.

A.±0.5 PPM, when the radio is at 26.5°C (79.8°F).

B.±2 PPM at any other temperature within the range

C.The specification limit (±2 PPM or ±5 PPM) at any temperature within the ranges

If frequency adjustment is required, lift up the cover on the top of the ICOM (where present) to expose the adjustment trimmer. Depending upon the type of frequency measuring equipment that is available, any of the following procedures may be used:

A.DIRECT MEASUREMENT IN THE INJECTION CHAIN

1.WITH A FREQUENCY COUNTER. "Count" the frequency at the junction of C416 and L403 on the Oscillator/Multiplier Board. The frequency measured at this point is 9 times the ICOM frequency. NOTE: The output from the ICOM itself is not sufficiently sinusoidal for reliable operation with most frequency counters.

2.WITH A COMMUNICATION MONITOR (for example: Cushman Model

B.STANDARD "ON FREQUENCY" SIGNAL AT THE RECEIVER INPUT (Generated from a COMMUNICATION MONI- TOR, for example: Cushman Model

1.WITH A FREQUENCY COUNTER. "Count" the developed IF frequency at the top of

2.WITH AN 11.2 MHz IF FREQUENCY STANDARD (for example: Model 4EX9A10). Loosely couple the IF frequency standard to the IF signal path to create a heterodyne with the developed IF frequency. The resultant "beat frequency" can be monitored by either of the following methods:

a. Audible "beat frequency" from the receiver speaker (this requires careful frequency adjustment of the frequency standard).

NOTE

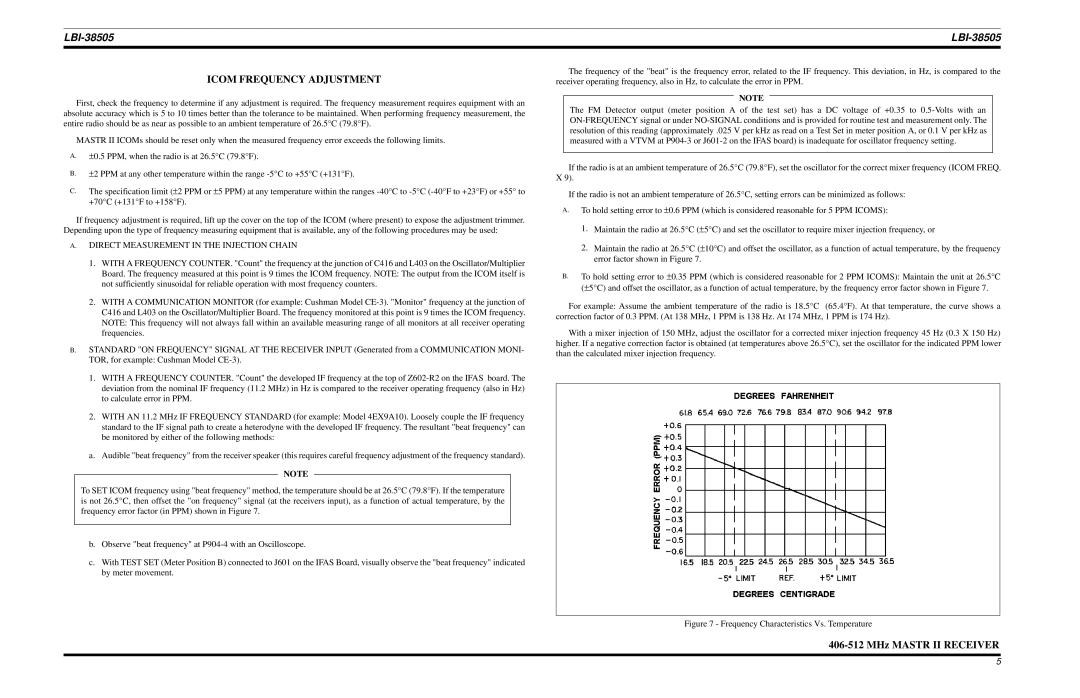

To SET ICOM frequency using "beat frequency" method, the temperature should be at 26.5°C (79.8°F). If the temperature is not 26.5°C, then offset the "on frequency" signal (at the receivers input), as a function of actual temperature, by the frequency error factor (in PPM) shown in Figure 7.

b.Observe "beat frequency" at

c.With TEST SET (Meter Position B) connected to J601 on the IFAS Board, visually observe the "beat frequency" indicated by meter movement.

The frequency of the "beat" is the frequency error, related to the IF frequency. This deviation, in Hz, is compared to the receiver operating frequency, also in Hz, to calculate the error in PPM.

NOTE

The FM Detector output (meter position A of the test set) has a DC voltage of +0.35 to

If the radio is at an ambient temperature of 26.5°C (79.8°F), set the oscillator for the correct mixer frequency (ICOM FREQ. X 9).

If the radio is not an ambient temperature of 26.5°C, setting errors can be minimized as follows:

A.To hold setting error to ±0.6 PPM (which is considered reasonable for 5 PPM ICOMS):

1.Maintain the radio at 26.5°C ( ±5°C) and set the oscillator to require mixer injection frequency, or

2.Maintain the radio at 26.5°C ( ±10°C) and offset the oscillator, as a function of actual temperature, by the frequency error factor shown in Figure 7.

B.To hold setting error to ±0.35 PPM (which is considered reasonable for 2 PPM ICOMS): Maintain the unit at 26.5°C (±5°C) and offset the oscillator, as a function of actual temperature, by the frequency error factor shown in Figure 7.

For example: Assume the ambient temperature of the radio is 18.5°C (65.4°F). At that temperature, the curve shows a correction factor of 0.3 PPM. (At 138 MHz, 1 PPM is 138 Hz. At 174 MHz, 1 PPM is 174 Hz).

With a mixer injection of 150 MHz, adjust the oscillator for a corrected mixer injection frequency 45 Hz (0.3 X 150 Hz) higher. If a negative correction factor is obtained (at temperatures above 26.5°C), set the oscillator for the indicated PPM lower than the calculated mixer injection frequency.

Figure 7 - Frequency Characteristics Vs. Temperature

5