• Check belt tension. | A 3 lb. force | 3 Lb. |

should deflect the belt | 3/4 inches (see | 3/4 Inches |

Fig. 11). Readjust belt if needed. |

| |

• Oil bearings. The blower bearings and cooler motor in this unit should be oiled with a few drops of

does not need oil if it has no oil lines for oiling. Motors that have no oil lines are lifetime oiled at the factory and require no further oiling for the life of the unit.

![]() CAUTION: Do not over oil. Over oiling can cause motor burn out, due to excessive oil getting into motor winding.

CAUTION: Do not over oil. Over oiling can cause motor burn out, due to excessive oil getting into motor winding.

spout and check for any blockage. After cleaning, reinstall the base onto the pump. Press firmly to make sure it is secure. Reattach the pump to the mount in the cooler using the plastic retainer to ensure that the pump will not overturn. Do not forget to replace the spout and water delivery tube onto the pump outlet.

•Check bleed-off valve to be sure it is not clogged.

Winter Shut-Down

• Drain water. Always drain all of the water out of the cooler and water |

supply line when not in use for prolonged periods, and particularly |

at the end of the season. Keep the water line disconnected from both |

the unit and water supply so that it does not freeze. |

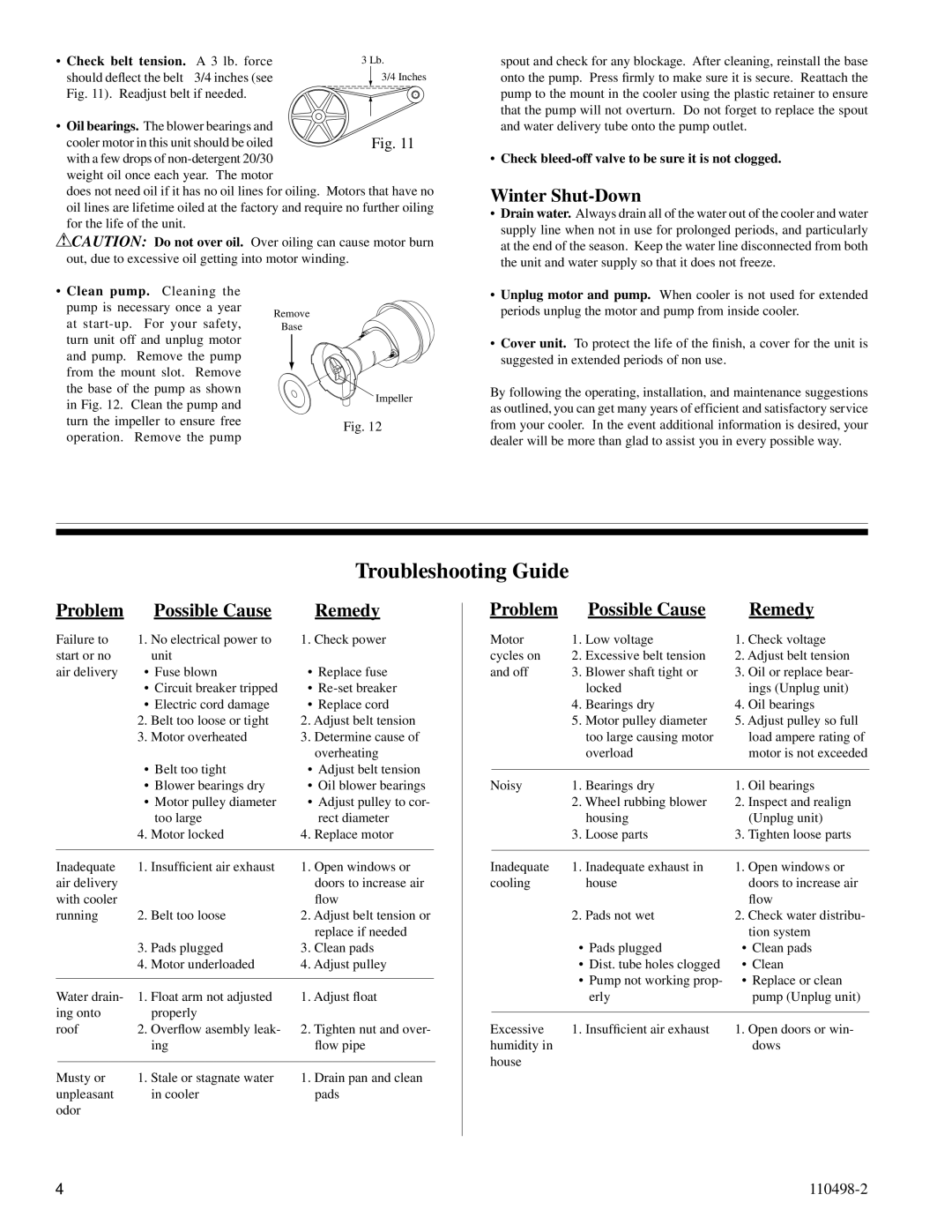

•Clean pump. Cleaning the pump is necessary once a year at

Remove

Base

Impeller

Fig. 12

• Unplug motor and pump. When cooler is not used for extended |

periods unplug the motor and pump from inside cooler. |

• Cover unit. To protect the life of the finish, a cover for the unit is |

suggested in extended periods of non use. |

By following the operating, installation, and maintenance suggestions as outlined, you can get many years of efficient and satisfactory service from your cooler. In the event additional information is desired, your dealer will be more than glad to assist you in every possible way.

Troubleshooting Guide

Problem |

| Possible Cause |

| Remedy |

| |

Failure to | 1. | No electrical power to | 1. | Check power |

| |

start or no |

| unit |

|

|

| |

air delivery | • Fuse blown | • Replace fuse |

| |||

|

| • Circuit breaker tripped | • |

| ||

|

| • Electric cord damage | • Replace cord |

| ||

|

| 2. | Belt too loose or tight | 2. Adjust belt tension |

| |

|

| 3. | Motor overheated | 3. | Determine cause of |

|

|

|

|

|

| overheating |

|

|

| • Belt too tight | • Adjust belt tension |

| ||

|

| • Blower bearings dry | • Oil blower bearings |

| ||

|

| • Motor pulley diameter | • Adjust pulley to cor- |

| ||

|

|

| too large |

| rect diameter |

|

|

| 4. | Motor locked | 4. | Replace motor |

|

|

|

|

|

|

|

|

Inadequate | 1. | Insufficient air exhaust | 1. | Open windows or |

| |

air delivery |

|

|

| doors to increase air |

| |

with cooler |

|

|

| flow |

| |

running | 2. | Belt too loose | 2. Adjust belt tension or |

| ||

|

|

|

|

| replace if needed |

|

|

| 3. | Pads plugged | 3. | Clean pads |

|

|

| 4. | Motor underloaded | 4. Adjust pulley |

| |

|

|

|

| |||

Water drain- 1. Float arm not adjusted | 1. Adjust float |

| ||||

ing onto |

| properly |

|

|

| |

roof | 2. | Overflow asembly leak- | 2. Tighten nut and over- |

| ||

|

|

| ing |

| flow pipe |

|

|

|

|

|

|

|

|

Musty or | 1. | Stale or stagnate water | 1. | Drain pan and clean |

| |

unpleasant |

| in cooler |

| pads |

| |

odor |

|

|

|

|

| |

Problem |

| Possible Cause |

| Remedy | |

Motor | 1. | Low voltage | 1. | Check voltage | |

cycles on | 2. | Excessive belt tension | 2. Adjust belt tension | ||

and off | 3. | Blower shaft tight or | 3. | Oil or replace bear- | |

|

|

| locked |

| ings (Unplug unit) |

|

| 4. | Bearings dry | 4. | Oil bearings |

|

| 5. | Motor pulley diameter | 5. Adjust pulley so full | |

|

|

| too large causing motor |

| load ampere rating of |

|

|

| overload |

| motor is not exceeded |

|

|

|

|

|

|

Noisy | 1. | Bearings dry | 1. | Oil bearings | |

|

| 2. Wheel rubbing blower | 2. | Inspect and realign | |

|

|

| housing |

| (Unplug unit) |

|

| 3. | Loose parts | 3. Tighten loose parts | |

|

|

|

|

|

|

Inadequate | 1. | Inadequate exhaust in | 1. | Open windows or | |

cooling |

| house |

| doors to increase air | |

|

|

|

|

| flow |

|

| 2. | Pads not wet | 2. | Check water distribu- |

|

|

|

|

| tion system |

|

| • Pads plugged | • Clean pads | ||

|

| • Dist. tube holes clogged | • Clean | ||

|

| • Pump not working prop- | • Replace or clean | ||

|

|

| erly |

| pump (Unplug unit) |

|

|

|

|

|

|

Excessive | 1. | Insufficient air exhaust | 1. | Open doors or win- | |

humidity in |

|

|

| dows | |

house |

|

|

|

| |

4 |

|