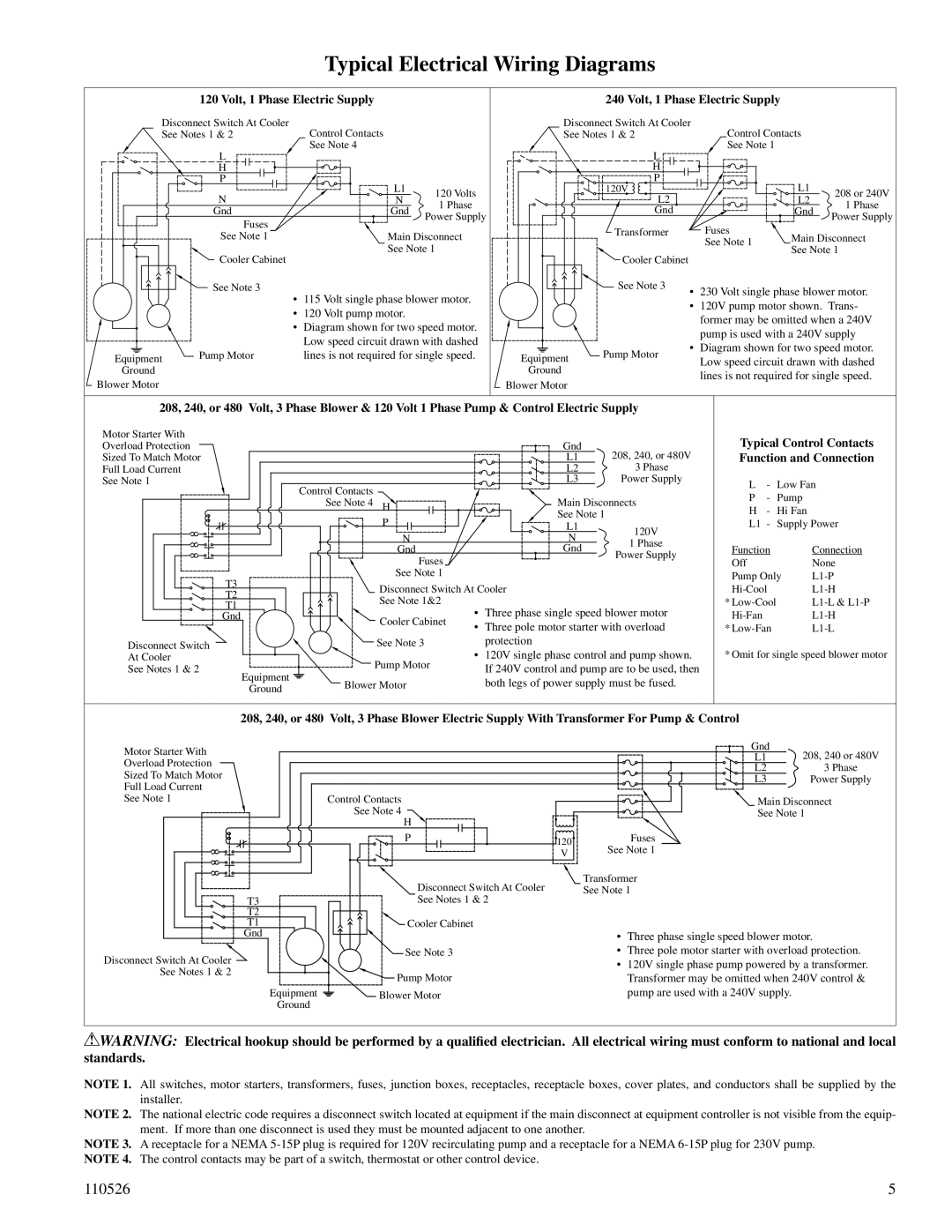

Typical Electrical Wiring Diagrams

120 Volt, 1 Phase Electric Supply

240 Volt, 1 Phase Electric Supply

Disconnect Switch At Cooler

See Notes 1 & 2

L

H

P

N

Gnd

Fuses

See Note 1

Cooler Cabinet

See Note 3

Equipment ![]() Pump Motor

Pump Motor

Ground

Blower Motor

Control Contacts

![]() See Note 4

See Note 4

L1 | 120 Volts | |

N | ||

1 Phase | ||

Gnd | ||

Power Supply | ||

|

Main Disconnect

See Note 1

•115 Volt single phase blower motor.

•120 Volt pump motor.

•Diagram shown for two speed motor. Low speed circuit drawn with dashed lines is not required for single speed.

Disconnect Switch At Cooler | Control Contacts |

| |||

See Notes 1 & 2 |

|

| |||

| L |

| See Note 1 |

|

|

|

|

|

|

| |

| H |

|

|

|

|

| P |

|

| L1 |

|

| 120V |

|

| 208 or 240V | |

| L2 |

|

| L2 | |

|

|

| 1 Phase | ||

| Gnd |

|

| Gnd | |

|

|

| Power Supply | ||

|

|

| Fuses |

| |

| Transformer |

| Main Disconnect | ||

|

|

| See Note 1 | ||

|

|

| See Note 1 | ||

| Cooler Cabinet |

|

| ||

|

|

|

|

| |

| See Note 3 | • | 230 Volt single phase blower motor. | ||

|

| ||||

|

| • | 120V pump motor shown. Trans- | ||

|

|

| former may be omitted when a 240V | ||

|

|

| pump is used with a 240V supply | ||

Equipment | Pump Motor | • | Diagram shown for two speed motor. | ||

| Low speed circuit drawn with dashed | ||||

|

| ||||

Ground |

|

| lines is not required for single speed. | ||

Blower Motor |

|

| |||

|

|

|

|

| |

208, 240, or 480 Volt, 3 Phase Blower & 120 Volt 1 Phase Pump & Control Electric Supply

Motor Starter With

Overload Protection

Sized To Match Motor

Full Load Current

See Note 1

T3

T2

T1

Gnd

Disconnect Switch

At Cooler

See Notes 1 & 2

Equipment

Ground

|

| Gnd | 208, 240, or 480V | |

|

| L1 | ||

|

| L2 | 3 Phase | |

Control Contacts |

| L3 | Power Supply | |

| Main Disconnects | |||

See Note 4 H |

| |||

P |

| See Note 1 |

| |

| L1 | 120V | ||

N |

| N | ||

| 1 Phase | |||

Gnd |

| Gnd | ||

| Power Supply | |||

Fuses |

|

| ||

|

|

| ||

See Note 1 |

|

|

| |

Disconnect Switch At Cooler |

| |||

See Note 1&2 | • | Three phase single speed blower motor | ||

Cooler Cabinet | ||||

• | Three pole motor starter with overload | |||

| ||||

See Note 3 |

| protection |

| |

Pump Motor | • | 120V single phase control and pump shown. | ||

| If 240V control and pump are to be used, then | |||

|

| |||

Blower Motor |

| both legs of power supply must be fused. | ||

Typical Control Contacts Function and Connection

L- Low Fan P - Pump H - Hi Fan

L1 - Supply Power

Function | Connection |

Off | None |

Pump Only | |

* | |

* |

* Omit for single speed blower motor

208, 240, or 480 Volt, 3 Phase Blower Electric Supply With Transformer For Pump & Control

Motor Starter With |

|

|

Overload Protection |

|

|

Sized To Match Motor |

|

|

Full Load Current |

|

|

See Note 1 | Control Contacts |

|

| See Note 4 |

|

| H |

|

| P | 120 |

|

| V |

| Disconnect Switch At Cooler |

|

T3 | See Notes 1 & 2 |

|

T2 |

|

|

T1 | Cooler Cabinet |

|

Gnd |

|

|

Disconnect Switch At Cooler | See Note 3 |

|

|

| |

See Notes 1 & 2 | Pump Motor |

|

|

| |

Equipment | Blower Motor |

|

Ground |

|

|

Gnd | 208, 240 or 480V |

L1 | |

L2 | 3 Phase |

L3 | Power Supply |

Main Disconnect

See Note 1

Fuses

See Note 1

Transformer

See Note 1

•Three phase single speed blower motor.

•Three pole motor starter with overload protection.

•120V single phase pump powered by a transformer. Transformer may be omitted when 240V control & pump are used with a 240V supply.

![]() WARNING: Electrical hookup should be performed by a qualified electrician. All electrical wiring must conform to national and local standards.

WARNING: Electrical hookup should be performed by a qualified electrician. All electrical wiring must conform to national and local standards.

NOTE 1. All switches, motor starters, transformers, fuses, junction boxes, receptacles, receptacle boxes, cover plates, and conductors shall be supplied by the installer.

NOTE 2. The national electric code requires a disconnect switch located at equipment if the main disconnect at equipment controller is not visible from the equip- ment. If more than one disconnect is used they must be mounted adjacent to one another.

NOTE 3. A receptacle for a NEMA

110526 | 5 |