Maintenance

19. Install the rear tires and torque lug nuts to

20. Remove jack stands.

Electric Clutch Adjustment

No adjustment necessary. However on units with 60 inch decks, when the clutch brake has worn to the point where the clutch no longer engages consistently, the shim can be removed to extend the clutch life.

Figure 30

1. 2 inch height of cut location

E.Start the mower while in the operator position.

![]()

![]() WARNING

WARNING

Engine must be running and drive wheels must be turning so adjustments can be performed. Contact with moving parts or hot surfaces may cause personal injury.

Keep fingers, hands, and clothing clear of rotating components and hot surfaces.

F.Release the park brake so the handle rests on the 1/2 x 6 inch rod or bolt.

G.Move the throttle to high idle.

H.Move both motion control levers to the full forward position and hold for 15 seconds.

I.Move both motion control levers to the full reverse position and hold for 15 seconds.

J.Turn off the engine and completely release the park brake by removing the 1/2 x 6 inch rod or bolt.

K.Allow the hubs to cool until they are cool enough to safely touch.

L.Rotate the drive wheel release handle to the “released” position. Refer to the Drive Wheel Release Valves section in Operation.

M.Readjust both brakes following the procedure in steps 10 through 14.

18.Rotate the drive wheel release handle to the “operating” position. Refer to the Drive Wheel Release Valves section in Operation.

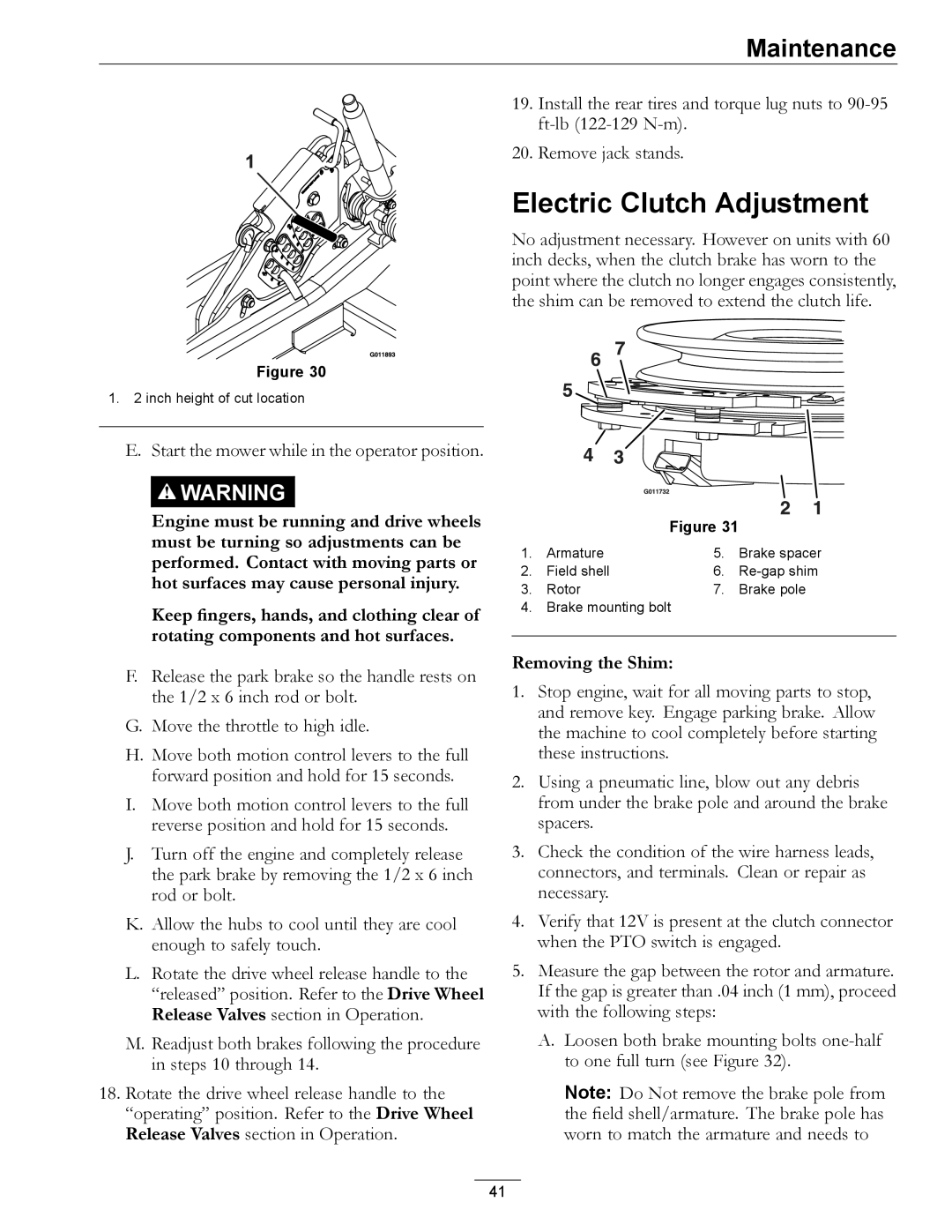

Figure 31

1. | Armature | 5. | Brake spacer |

2. | Field shell | 6. | |

3. | Rotor | 7. | Brake pole |

4. | Brake mounting bolt |

|

|

Removing the Shim:

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Allow the machine to cool completely before starting these instructions.

2.Using a pneumatic line, blow out any debris from under the brake pole and around the brake spacers.

3.Check the condition of the wire harness leads, connectors, and terminals. Clean or repair as necessary.

4.Verify that 12V is present at the clutch connector when the PTO switch is engaged.

5.Measure the gap between the rotor and armature. If the gap is greater than .04 inch (1 mm), proceed with the following steps:

A.Loosen both brake mounting bolts

Note: Do Not remove the brake pole from the field shell/armature. The brake pole has worn to match the armature and needs to

41