Maintenance

Figure 39

RH Motion Control Shown

1. Screw | 3. Motion control lever |

2.Cover plate

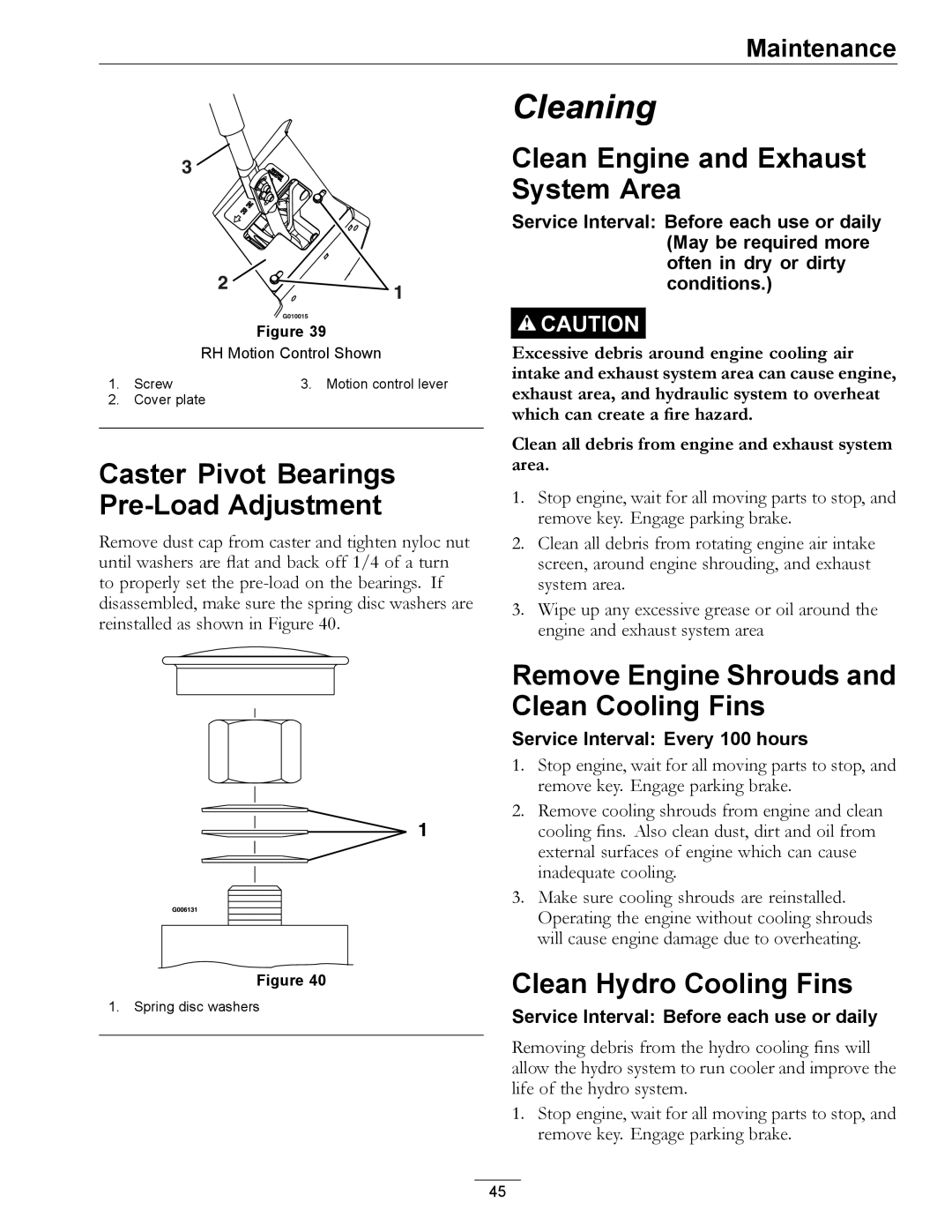

Caster Pivot Bearings Pre-Load Adjustment

Remove dust cap from caster and tighten nyloc nut until washers are flat and back off 1/4 of a turn to properly set the

Cleaning

Clean Engine and Exhaust System Area

Service Interval: Before each use or daily (May be required more often in dry or dirty conditions.)

![]()

![]() CAUTION

CAUTION

Excessive debris around engine cooling air intake and exhaust system area can cause engine, exhaust area, and hydraulic system to overheat which can create a fire hazard.

Clean all debris from engine and exhaust system area.

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Clean all debris from rotating engine air intake screen, around engine shrouding, and exhaust system area.

3.Wipe up any excessive grease or oil around the engine and exhaust system area

Figure 40

1.Spring disc washers

Remove Engine Shrouds and Clean Cooling Fins

Service Interval: Every 100 hours

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Remove cooling shrouds from engine and clean cooling fins. Also clean dust, dirt and oil from external surfaces of engine which can cause inadequate cooling.

3.Make sure cooling shrouds are reinstalled. Operating the engine without cooling shrouds will cause engine damage due to overheating.

Clean Hydro Cooling Fins

Service Interval: Before each use or daily

Removing debris from the hydro cooling fins will allow the hydro system to run cooler and improve the life of the hydro system.

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

45