LZDS specifications

The Exmark LZDS stands as a benchmark in the world of commercial lawn care equipment. Designed specifically for landscape professionals, the LZDS combines power, efficiency, and precision to deliver exceptional results in varied conditions. One of its hallmark features is the robust engine, engineered to handle large-scale mowing tasks without sacrificing reliability. The Exmark LZDS is equipped with a powerful Kohler Command Pro engine, which provides superior torque and smooth operation, making it ideal for tackling tough terrains.The LZDS showcases Exmark’s signature UltraCut deck technology, which is designed to enhance cutting performance and deliver a clean, even cut. The deck comes in various sizes, allowing users to choose the perfect fit based on their specific mowing requirements. The heavy-duty construction ensures durability, while the unique design minimizes clumping and provides improved airflow, contributing to a flawless finish on every lawn.

One of the standout characteristics of the Exmark LZDS is its zero-turn capability. This feature allows for unparalleled maneuverability, enabling operators to navigate complex landscapes with ease. The intuitive controls and comfortable seating position reduce operator fatigue, allowing for longer work sessions without discomfort. The ergonomic control layout makes it easy to adjust settings on the fly, enhancing overall productivity and precision.

In addition to its mechanical advantages, the LZDS also incorporates sophisticated technologies aimed at optimizing the mowing process. The mower features a practical SmartPower system, which automatically adjusts the engine’s power output based on the load, ensuring optimal performance and fuel efficiency. This technology helps professionals achieve the best results while reducing operational costs.

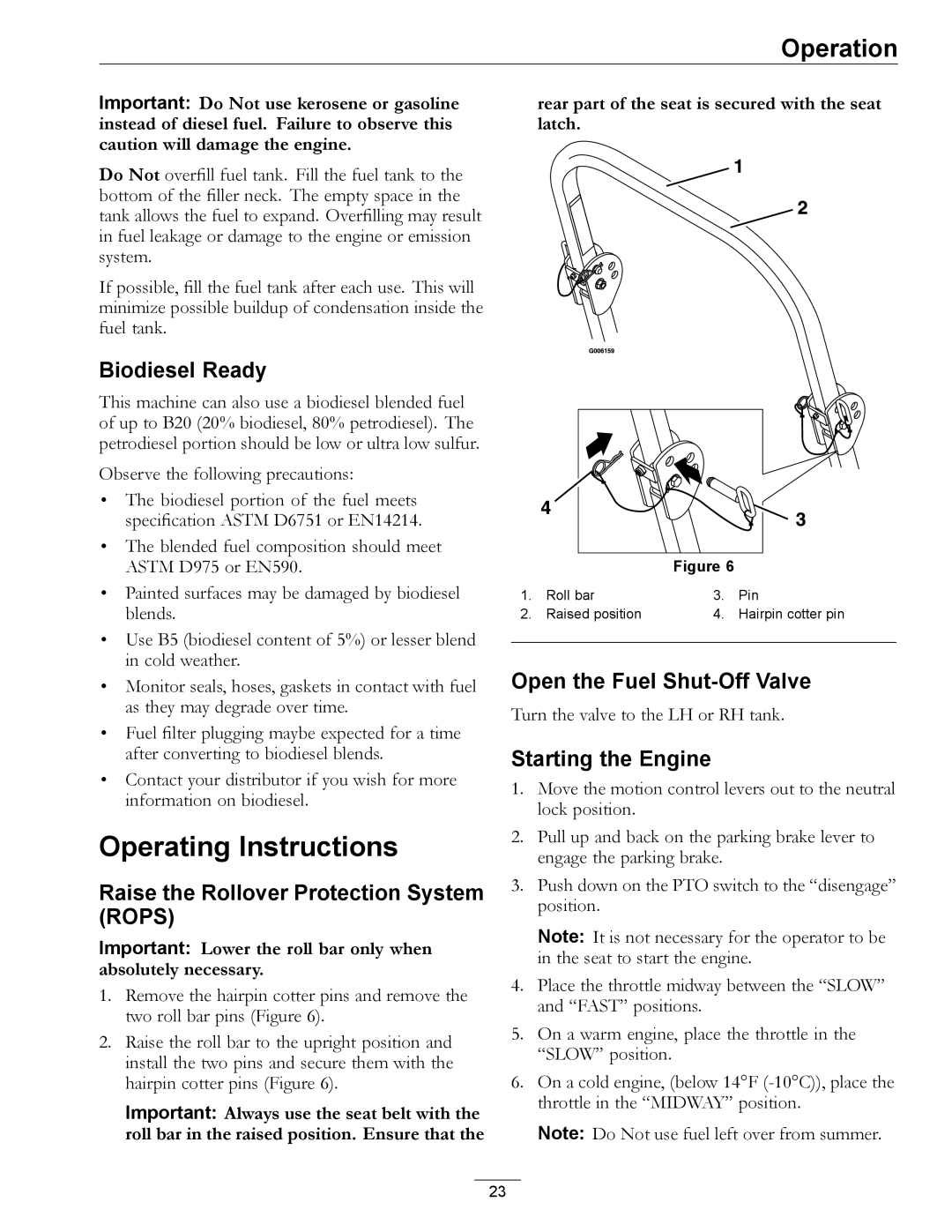

Safety is a paramount consideration in the design of the LZDS, which includes features like a rollover protection system and easy-to-reach controls positioned for quick access. The mower’s durable design is complemented by easy-access maintenance points, making routine servicing straightforward.

In conclusion, the Exmark LZDS embodies the perfect fusion of innovation, power, and efficiency. With its high-performance engine, advanced cutting technology, and user-friendly features, it is tailored for professionals seeking reliable and effective solutions for lawn care. Whether it's maintaining expansive commercial properties or tackling intricate residential landscapes, the Exmark LZDS delivers outstanding performance that caters to the demanding needs of the landscaping industry.