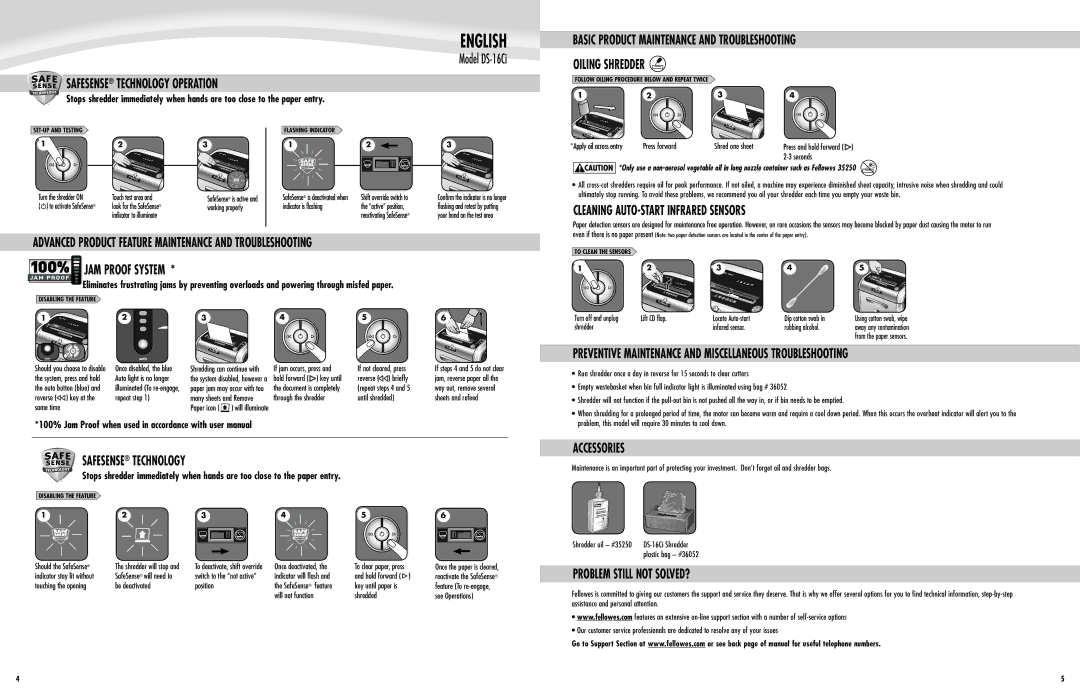

SAFESENSE® TECHNOLOGY OPERATION

Stops shredder immediately when hands are too close to the paper entry.

ENGLISH

Model

BASIC PRODUCT MAINTENANCE AND TROUBLESHOOTING

OILING SHREDDER ![]()

FOLLOW OILING PROCEDURE BELOW AND REPEAT TWICE

1 | 2 | 3 | 3 |

54 |

1 | 2 | 3 |

Turn the shredder ON | Touch test area and | SafeSense® is active and |

( ) to activate SafeSense® | look for the SafeSense® | working properly |

| indicator to illuminate |

|

FLASHING INDICATOR

12

SafeSense® is deactivated when | Shift override switch to |

indicator is flashing | the “active” position, |

| reactivating SafeSense® |

3

Confirm the indicator is no longer flashing and retest by putting your hand on the test area

*Apply oil across entry | Press forward | Shred one sheet | Press and hold forward ( ) |

|

|

|

|

![]()

![]()

![]()

![]()

![]()

![]()

![]() *Only use a

*Only use a

•All

CLEANING

ADVANCED PRODUCT FEATURE MAINTENANCE AND TROUBLESHOOTING

JAM PROOF SYSTEM *

Eliminates frustrating jams by preventing overloads and powering through misfed paper.

DISABLING THE FEATURE

Paper detection sensors are designed for maintenance free operation. However, on rare occasions the sensors may become blocked by paper dust causing the motor to run even if there is no paper present (Note: two paper detection sensors are located in the center of the paper entry).

TO CLEAN THE SENSORS |

|

|

|

|

1 | 2 | 3 | 4 | 5 |

1

AUTO

Should you choose to disable the system, press and hold the auto button (blue) and reverse (![]() ) key at the same time

) key at the same time

2

AUTO

Once disabled, the blue Auto light is no longer illuminated (To

3

354

Shredding can continue with | If jam occurs, press and | |

the system disabled, however a | hold forward ( ) key until | |

paper jam may occur with too | the document is completely | |

many sheets and Remove | through the shredder | |

Paper icon ( | ) will illuminate |

|

3

5

If not cleared, press reverse (![]() ) briefly (repeat steps 4 and 5 until shredded)

) briefly (repeat steps 4 and 5 until shredded)

6 ![]()

![]()

![]()

If steps 4 and 5 do not clear jam, reverse paper all the way out, remove several sheets and refeed

Turn off and unplug | Lift CD flap. | Locate | Dip cotton swab in | Using cotton swab, wipe |

shredder |

| infared sensor. | rubbing alcohol. | away any contamination |

|

|

|

| from the paper sensors. |

PREVENTIVE MAINTENANCE AND MISCELLANEOUS TROUBLESHOOTING

• | Run shredder once a day in reverse for 15 seconds to clear cutters |

• | Empty wastebasket when bin full indicator light is illuminated using bag # 36052 |

• | Shredder will not function if the |

• When shredding for a prolonged period of time, the motor can become warm and require a cool down period. When this occurs the overheat indicator will alert you to the | |

*100% Jam Proof when used in accordance with user manual

SAFESENSE® TECHNOLOGY

Stops shredder immediately when hands are too close to the paper entry.

DISABLING THE FEATURE |

|

|

|

|

|

1 | 2 | 3 | 4 | 3 | 6 |

5 |

Should the SafeSense® | The shredder will stop and | To deactivate, shift override | Once deactivated, the | To clear paper, press | Once the paper is cleared, |

indicator stay lit without | SafeSense® will need to | switch to the “not active“ | indicator will flash and | and hold forward ( ) | reactivate the SafeSense® |

touching the opening | be deactivated | position | the SafeSense® feature | key until paper is | feature (To |

|

|

| will not function | shredded | see Operations) |

problem, this model will require 30 minutes to cool down. |

ACCESSORIES

Maintenance is an important part of protecting your investment. Don’t forget oil and shredder bags.

Shredder oil – #35250 | |

| plastic bag – #36052 |

PROBLEM STILL NOT SOLVED?

Fellowes is committed to giving our customers the support and service they deserve. That is why we offer several options for you to find technical information,

•www.fellowes.com features an extensive

•Our customer service professionals are dedicated to resolve any of your issues

Go to Support Section at www.fellowes.com or see back page of manual for useful telephone numbers.

4 | 5 |