1400 EQ specifications

The Festool 1400 EQ is a premium plunge router designed for a wide range of woodworking tasks, blending precision, power, and user-friendly features. This machine stands out among its peers thanks to its advanced engineering and innovative technologies, making it an essential tool for both professionals and woodworking enthusiasts.One of the primary features of the Festool 1400 EQ is its robust motor, delivering 1400 watts of power. This powerful motor enables the router to handle a variety of materials, including hardwoods, softwoods, and composite materials. The variable speed control allows users to adjust the RPM from 10,000 to 24,000, providing optimal performance for different applications. Whether you are making intricate cuts or performing edge shaping, the speed control ensures precision and efficiency.

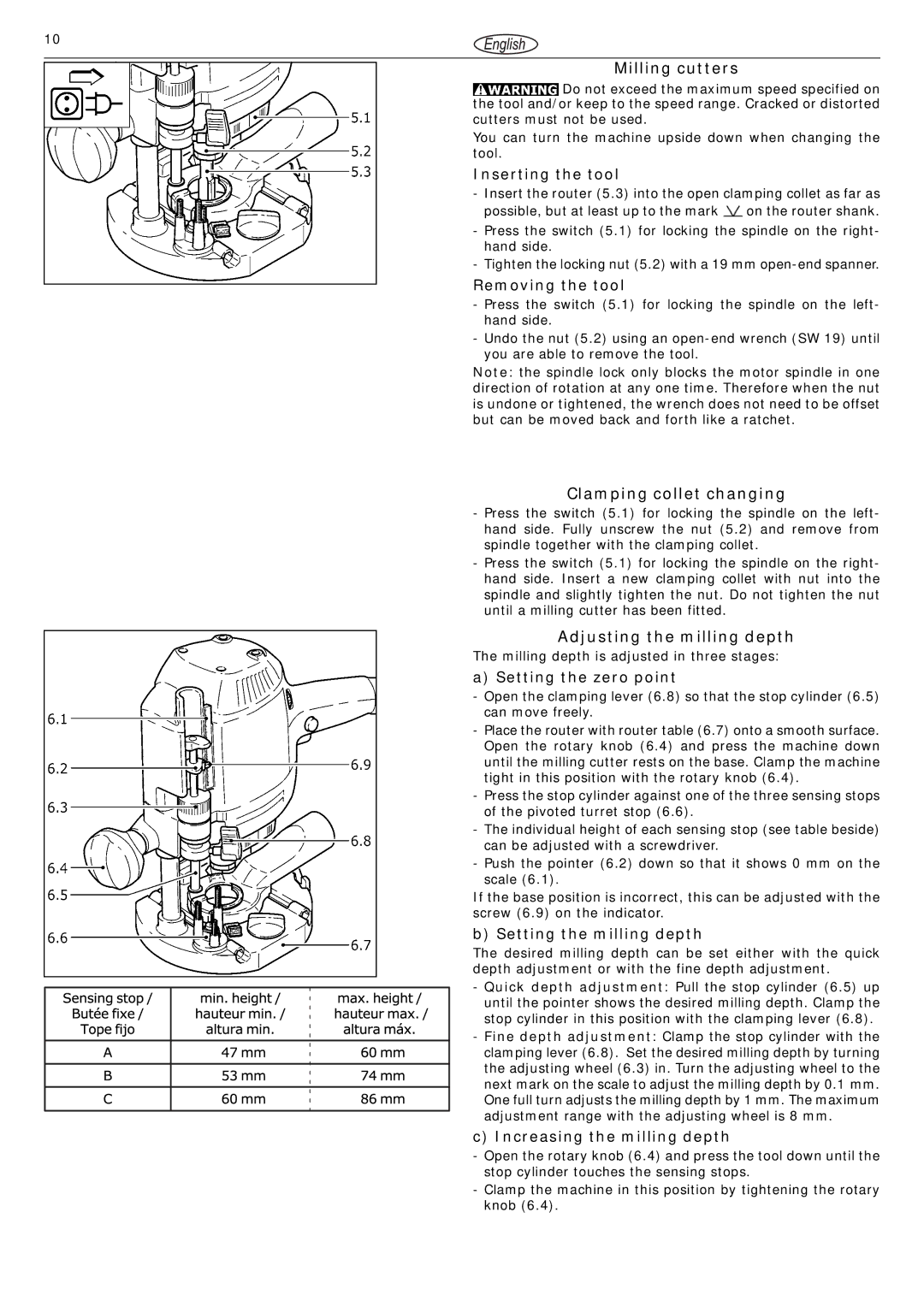

The design of the 1400 EQ is user-oriented, featuring an ergonomic handle that provides excellent grip and comfort during operation. The plunge depth can be easily adjusted with a single dial, allowing for precise routing depths without any tools. This feature is particularly beneficial for users who frequently switch between tasks, as it saves time and enhances productivity.

Festool's unique FastFix system further elevates the versatility of the 1400 EQ. This technology enables quick and easy bit changes without the need for additional tools, ensuring that users can swiftly adapt to various routing tasks. The large base and the option to attach a guide rail ensure stability and accuracy, making it easier to achieve clean, smooth cuts.

Another standout characteristic is the integrated dust extraction system. With the ability to connect to a Festool dust extractor, the 1400 EQ effectively minimizes dust and debris in the workspace, creating a cleaner and safer environment. This feature not only enhances visibility during work but also helps in maintaining a healthier atmosphere.

Durability and reliability are core attributes that Festool products are known for, and the 1400 EQ is no exception. Constructed with high-quality materials, this router is designed to withstand the rigors of heavy use, ensuring it remains a reliable tool for years to come.

In summary, the Festool 1400 EQ combines power, precision, and user-friendly features, making it a top choice for anyone serious about woodworking. Its advanced technologies and thoughtful design cater to a range of routing tasks, ensuring that users can achieve their desired results with ease and efficiency.