12

[10.4]. Each mark represents a routing depth of 0.1 mm. One complete turn of the wheel is 1 mm.

![]() Notes:

Notes:

fThe dial ring [10.5] can be turned sepa- rately to the "zero" setting.

fThe three marks [10.7] indicate the maxi- mum adjustment range of the adjusting wheel (20 mm) and the central position when aligned with the edge [10.8].

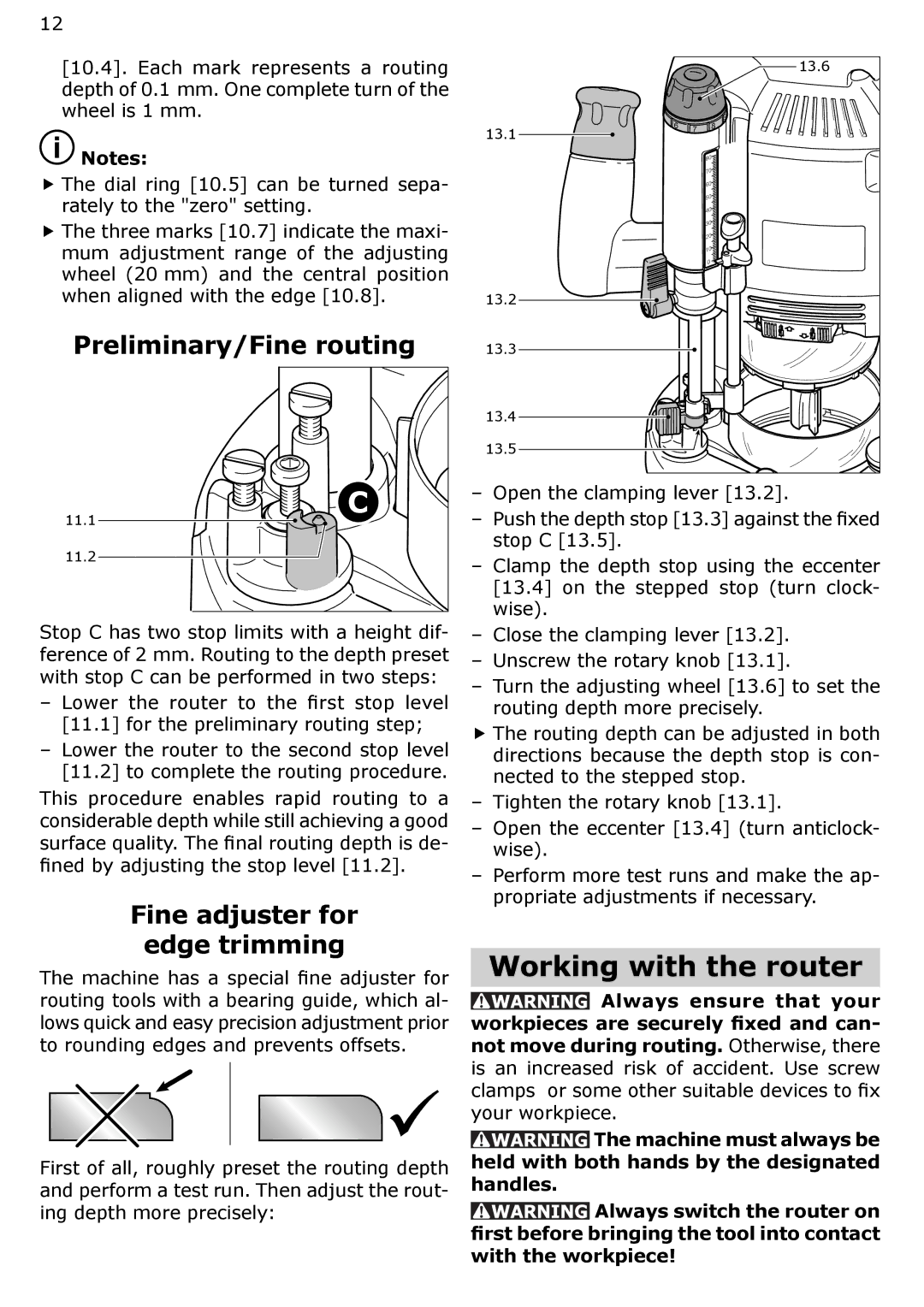

Preliminary/Fine routing

11.1 | C |

| |

11.2 |

|

Stop C has two stop limits with a height dif- ference of 2 mm. Routing to the depth preset with stop C can be performed in two steps:

–Lower the router to the first stop level [11.1] for the preliminary routing step;

–Lower the router to the second stop level [11.2] to complete the routing procedure.

This procedure enables rapid routing to a considerable depth while still achieving a good surface quality. The final routing depth is de- fined by adjusting the stop level [11.2].

Fine adjuster for

edge trimming

The machine has a special fine adjuster for routing tools with a bearing guide, which al- lows quick and easy precision adjustment prior to rounding edges and prevents offsets.

First of all, roughly preset the routing depth and perform a test run. Then adjust the rout- ing depth more precisely:

|

|

| 13.6 |

| 6 |

| 9 |

13.1 | 7 | 8 | |

|

| ||

|

|

| |

|

|

| 80 |

|

|

| 70 |

|

|

| 60 |

|

|

| 50 |

|

|

| 40 |

|

|

| 30 |

|

|

| 20 |

|

|

| 10 |

|

|

| 0 |

13.2 |

|

|

|

13.3 |

|

|

|

13.4 |

|

|

|

13.5 |

|

|

|

–Open the clamping lever [13.2].

–Push the depth stop [13.3] against the fixed stop C [13.5].

–Clamp the depth stop using the eccenter [13.4] on the stepped stop (turn clock- wise).

–Close the clamping lever [13.2].

–Unscrew the rotary knob [13.1].

–Turn the adjusting wheel [13.6] to set the routing depth more precisely.

fThe routing depth can be adjusted in both directions because the depth stop is con- nected to the stepped stop.

–Tighten the rotary knob [13.1].

–Open the eccenter [13.4] (turn anticlock- wise).

–Perform more test runs and make the ap- propriate adjustments if necessary.

Working with the router

![]() Always ensure that your workpieces are securely fixed and can- not move during routing. Otherwise, there is an increased risk of accident. Use screw clamps or some other suitable devices to fix your workpiece.

Always ensure that your workpieces are securely fixed and can- not move during routing. Otherwise, there is an increased risk of accident. Use screw clamps or some other suitable devices to fix your workpiece.

![]() The machine must always be held with both hands by the designated handles.

The machine must always be held with both hands by the designated handles.

![]() Always switch the router on first before bringing the tool into contact with the workpiece!

Always switch the router on first before bringing the tool into contact with the workpiece!