13

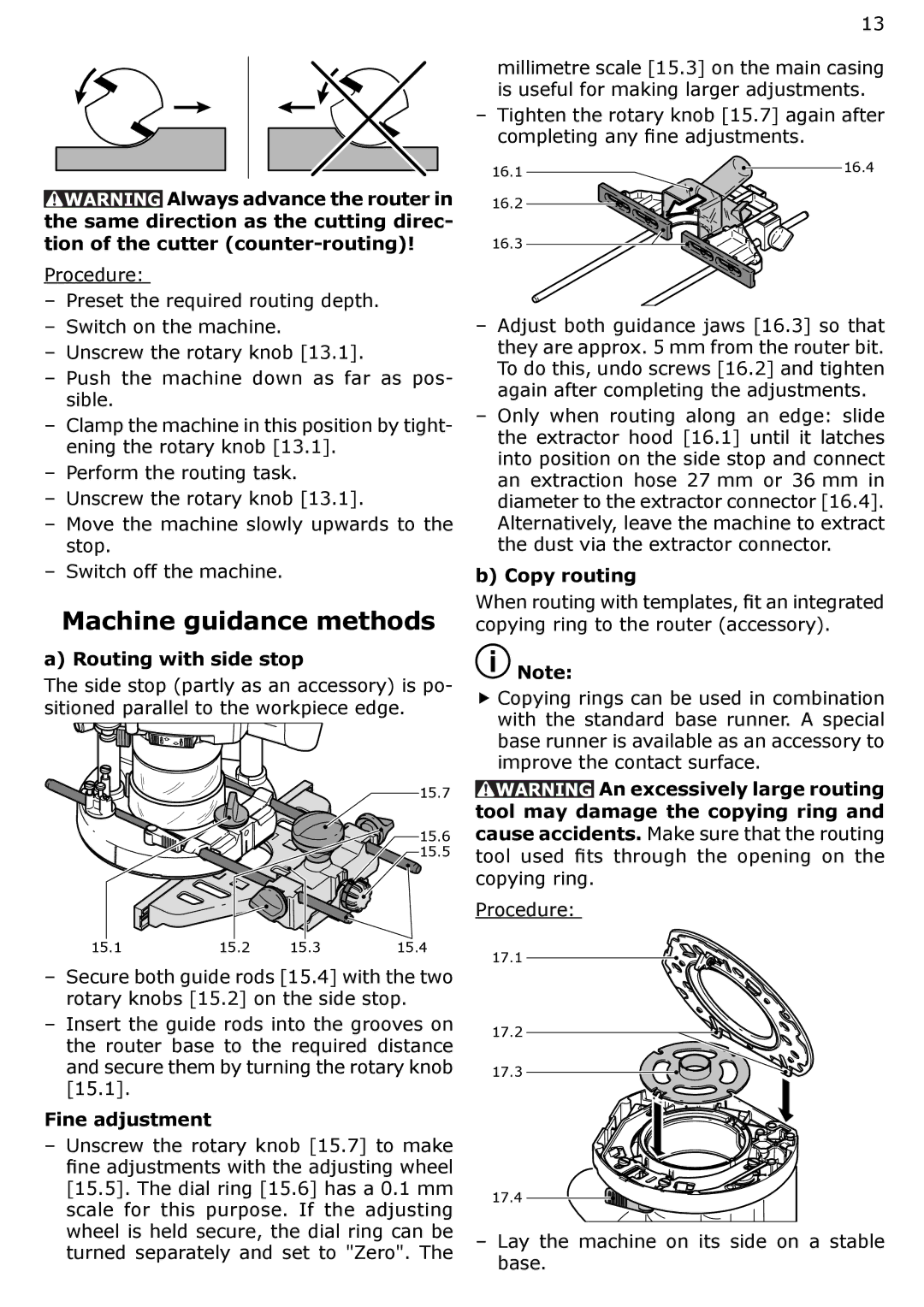

millimetre scale [15.3] on the main casing is useful for making larger adjustments.

–Tighten the rotary knob [15.7] again after completing any fine adjustments.

![]() Always advance the router in the same direction as the cutting direc- tion of the cutter

Always advance the router in the same direction as the cutting direc- tion of the cutter

Procedure:

–Preset the required routing depth.

–Switch on the machine.

–Unscrew the rotary knob [13.1].

–Push the machine down as far as pos- sible.

–Clamp the machine in this position by tight- ening the rotary knob [13.1].

–Perform the routing task.

–Unscrew the rotary knob [13.1].

–Move the machine slowly upwards to the stop.

–Switch off the machine.

Machine guidance methods

a) Routing with side stop

The side stop (partly as an accessory) is po- sitioned parallel to the workpiece edge.

16.1 | 16.4 |

|

16.2

16.3

–Adjust both guidance jaws [16.3] so that they are approx. 5 mm from the router bit. To do this, undo screws [16.2] and tighten again after completing the adjustments.

–Only when routing along an edge: slide the extractor hood [16.1] until it latches into position on the side stop and connect an extraction hose 27 mm or 36 mm in diameter to the extractor connector [16.4]. Alternatively, leave the machine to extract the dust via the extractor connector.

b) Copy routing

When routing with templates, fit an integrated copying ring to the router (accessory).

![]() Note:

Note:

fCopying rings can be used in combination with the standard base runner. A special base runner is available as an accessory to improve the contact surface.

15.7![]()

![]()

![]()

![]() An excessively large routing tool may damage the copying ring and

An excessively large routing tool may damage the copying ring and

15.6cause accidents. Make sure that the routing

15.5tool used fits through the opening on the copying ring.

Procedure:

15.1 | 15.2 | 15.3 | 15.4 |

–Secure both guide rods [15.4] with the two rotary knobs [15.2] on the side stop.

–Insert the guide rods into the grooves on the router base to the required distance and secure them by turning the rotary knob [15.1].

Fine adjustment

–Unscrew the rotary knob [15.7] to make fine adjustments with the adjusting wheel [15.5]. The dial ring [15.6] has a 0.1 mm scale for this purpose. If the adjusting wheel is held secure, the dial ring can be turned separately and set to "Zero". The

17.1

17.2

17.3

17.4

–Lay the machine on its side on a stable base.