Electrical connec- tion and operation

![]() The mains voltage must correspond to the voltage on the rating plate!

The mains voltage must correspond to the voltage on the rating plate!

To switch the tool on, push the safety sliding switch (1.1) forwards. The tool is switched off by gently

1.1 |

Extension cord

If an extension cord is required, it must have suf- ficient

Total Extension Cord | 25 | 50 | 100 | 150 | |

Lenght (feed) | |||||

|

|

|

| ||

Cord size (AWG) | 18 | 16 | 16 | 14 | |

|

|

|

|

|

Use only U.L. and CSA listed extension cords. Never use two extension cords together. Instead, use one long one.

Note: The lower the AWG number, the stronger the cord.

Electronic control

(2.1). This lets you optimize the sanding speed to suit the material (see "Working with the tool").

Constant speed

The

Temperature control

To prevent overheating, the safety electronics switch the tool off when it reaches a critical motor temperature. Let the tool cool down for approx.

Tool settings

![]() Always remove the power plug from the socket before carrying out any work on the power tool.

Always remove the power plug from the socket before carrying out any work on the power tool.

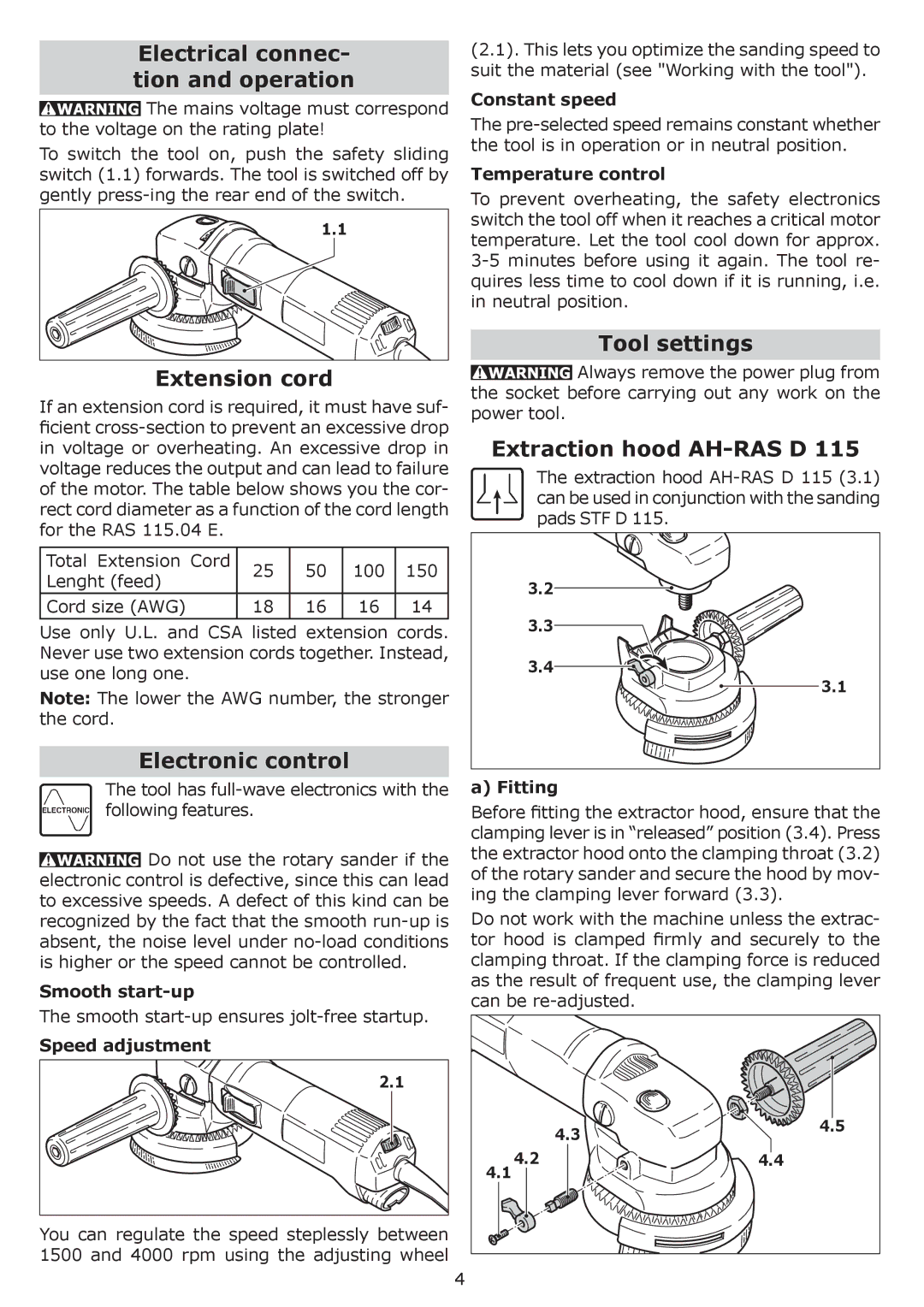

Extraction hood AH-RAS D 115

The extraction hood

3.2

3.3

3.4

3.1

The tool has | a) Fitting |

| ||

following features. | Before fitting the extractor hood, ensure that the | |||

| clamping lever is in “released” position (3.4). Press | |||

Do not use the rotary sander if the | the extractor hood onto the clamping throat (3.2) | |||

of the rotary sander and secure the hood by mov- | ||||

electronic control is defective, since this can lead | ||||

ing the clamping lever forward (3.3). | ||||

to excessive speeds. A defect of this kind can be | ||||

Do not work with the machine unless the extrac- | ||||

recognized by the fact that the smooth | ||||

absent, the noise level under | tor hood is clamped firmly and securely to the | |||

is higher or the speed cannot be controlled. | clamping throat. If the clamping force is reduced | |||

Smooth | as the result of frequent use, the clamping lever | |||

can be |

| |||

The smooth |

| |||

|

|

| ||

Speed adjustment |

|

|

| |

2.1 |

|

|

| |

|

| 4.3 | 4.5 | |

|

|

| ||

| 4.1 | 4.2 | 4.4 | |

|

|

| ||

You can regulate the speed steplessly between 1500 and 4000 rpm using the adjusting wheel

4