|

| 8.2 |

|

| o |

|

| |

|

| n |

8.1 | ||

|

|

|

|

| 9.1 |

9.2

9.3

The following basic rule applies for planing wood: Optimum surface quality will be ob- tained by pressing on the front planer platen when starting to plane and on the rear planer platen (end of workpiece) when continuing or finishing planing.

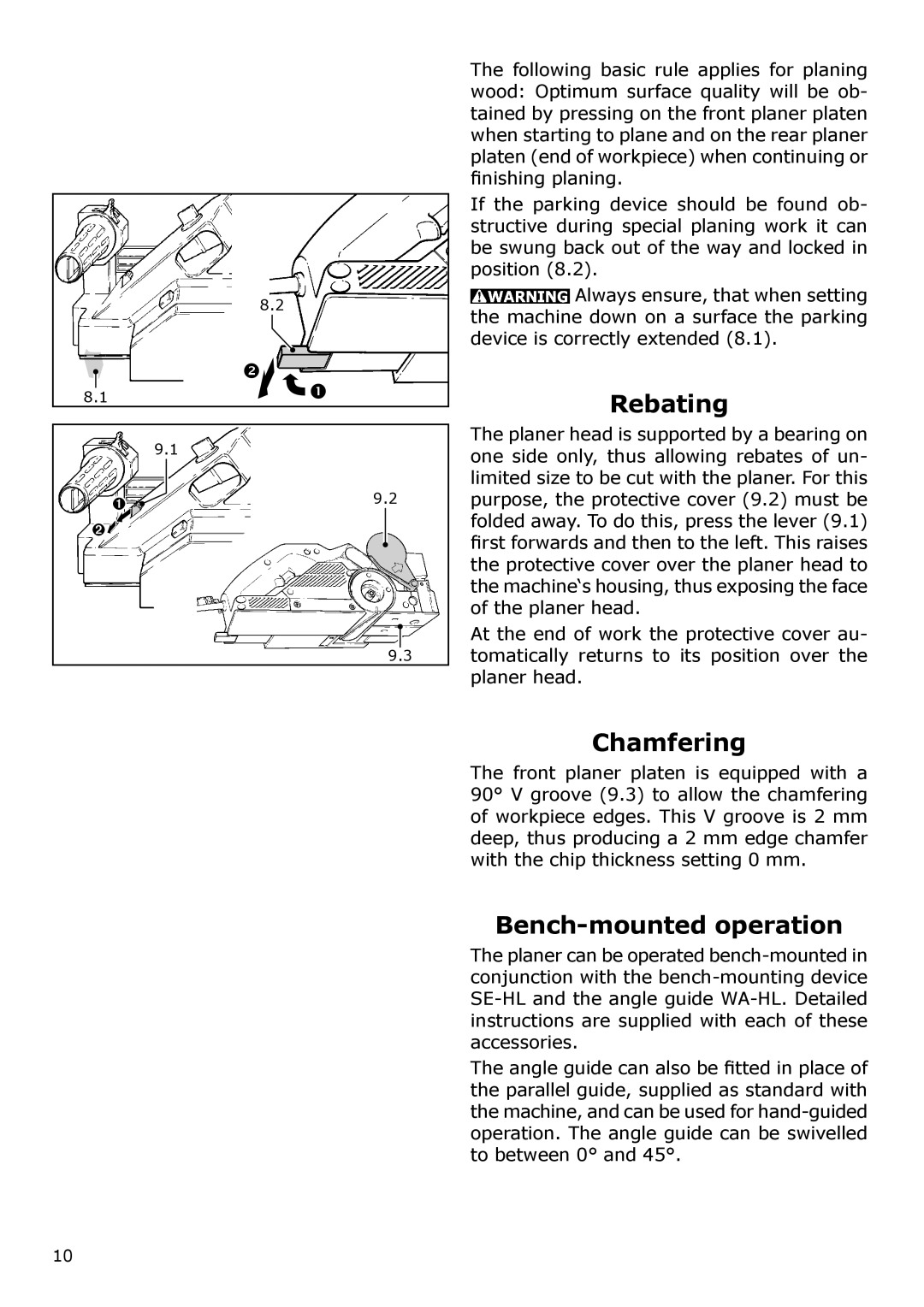

If the parking device should be found ob- structive during special planing work it can be swung back out of the way and locked in position (8.2).

![]() Always ensure, that when setting the machine down on a surface the parking device is correctly extended (8.1).

Always ensure, that when setting the machine down on a surface the parking device is correctly extended (8.1).

Rebating

The planer head is supported by a bearing on one side only, thus allowing rebates of un- limited size to be cut with the planer. For this purpose, the protective cover (9.2) must be folded away. To do this, press the lever (9.1) first forwards and then to the left. This raises the protective cover over the planer head to the machine‘s housing, thus exposing the face of the planer head.

At the end of work the protective cover au- tomatically returns to its position over the planer head.

Chamfering

The front planer platen is equipped with a 90° V groove (9.3) to allow the chamfering of workpiece edges. This V groove is 2 mm deep, thus producing a 2 mm edge chamfer with the chip thickness setting 0 mm.

Bench-mounted operation

The planer can be operated

The angle guide can also be fitted in place of the parallel guide, supplied as standard with the machine, and can be used for

10