(2,1)

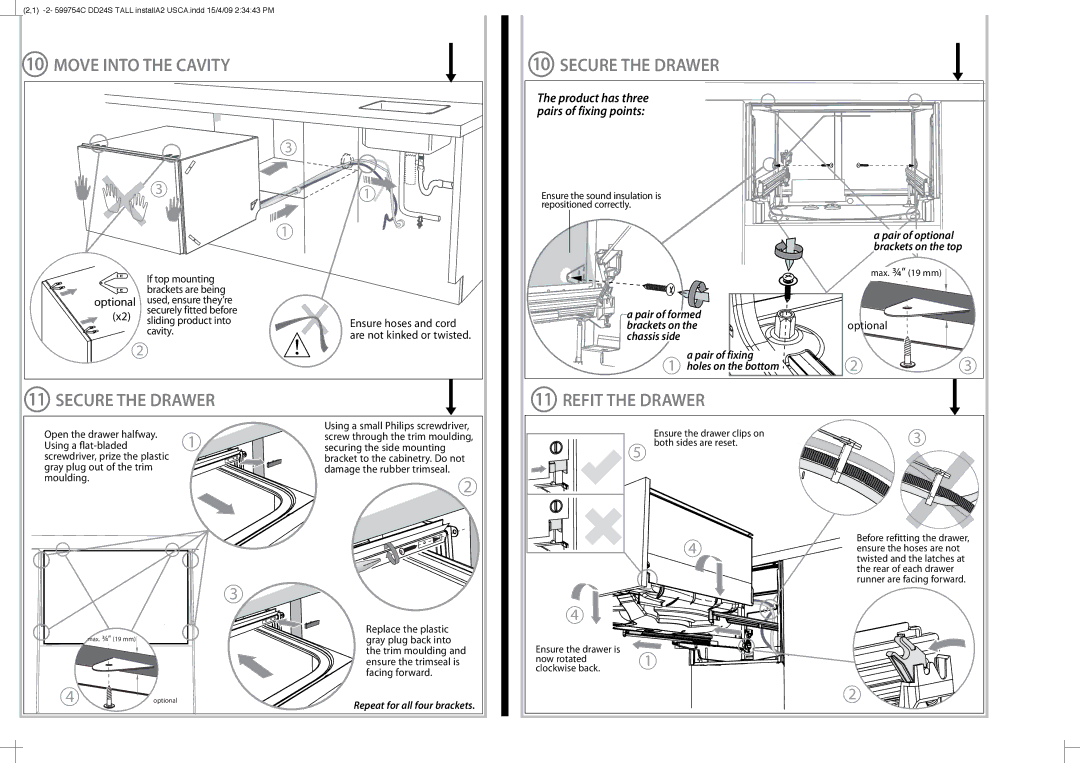

10MOVE INTO THE CAVITY

|

| 3 | |

| 3 | 1 | |

|

| ||

|

| 1 | |

| If top mounting |

| |

| brackets are being |

| |

optional | used, ensure they’re |

| |

(x2) | securely fitted before |

| |

sliding product into | Ensure hoses and cord | ||

| |||

| cavity. | are not kinked or twisted. | |

|

| ||

| 2 |

| |

11 SECURE THE DRAWER |

| ||

10SECURE THE DRAWER

The product has three pairs of fixing points:

Ensure the sound insulation is repositioned correctly.

| a pair of optional |

|

| brackets on the top |

|

| max. ¾” (19 mm) |

|

a pair of formed | optional |

|

brackets on the |

| |

chassis side |

|

|

a pair of fixing | 2 | 3 |

1 holes on the bottom |

11REFIT THE DRAWER

Open the drawer halfway. | 1 |

Using a | |

screwdriver, prize the plastic |

|

gray plug out of the trim |

|

moulding. |

|

Using a small Philips screwdriver, screw through the trim moulding, securing the side mounting bracket to the cabinetry. Do not damage the rubber trimseal.

2

Ensure the drawer clips on both sides are reset.

5

4

3

Before refitting the drawer, ensure the hoses are not twisted and the latches at the rear of each drawer runner are facing forward.

| 4 OPTIONAL |

| max. ¾” (19 mm) |

4 | optional |

3

Replace the plastic gray plug back into the trim moulding and ensure the trimseal is facing forward.

Repeat for all four brackets.

4

Ensure the drawer is

now rotated1 clockwise back.

2