To reduce condensation, insulate any ducting which passes through unheated areas.

Slope the duct gently downwards to the hood, to drain condensation and reduce lint build up. Avoid sag or loops in the duct as they may collect and store water and accumulate lint.

Before using an existing exhaust duct system for a dryer ensure that:

No plastic or other potentially combustible duct or flexible metal foil ducting has been used.

The duct is not pierced, kinked or crushed.

The duct does not exceed the maximum recommended length for the new dryer.

The exhaust hood damper opens and closes freely and with sufficient movement.

Static pressure in the exhaust ducting does not exceed 1 inch (250Pa), or is not less than 0 inches of water column (ie. negative pressure), when measured with a manometer in the first 6 inches of the duct, with the dryer running on Air Dry (no heat) setting.

The exhaust duct system meets all relevant local, state and national codes.

All ducting should be inspected and cleaned at least once a year to remove accumulated lint. Frequently check that the damper on the exhaust hood moves sufficiently and opens and shuts freely.

Mobile home installations

A Mobile Home Installation Kit is available (see Accessories page 4 and notes page 8).

Determine vent duct length

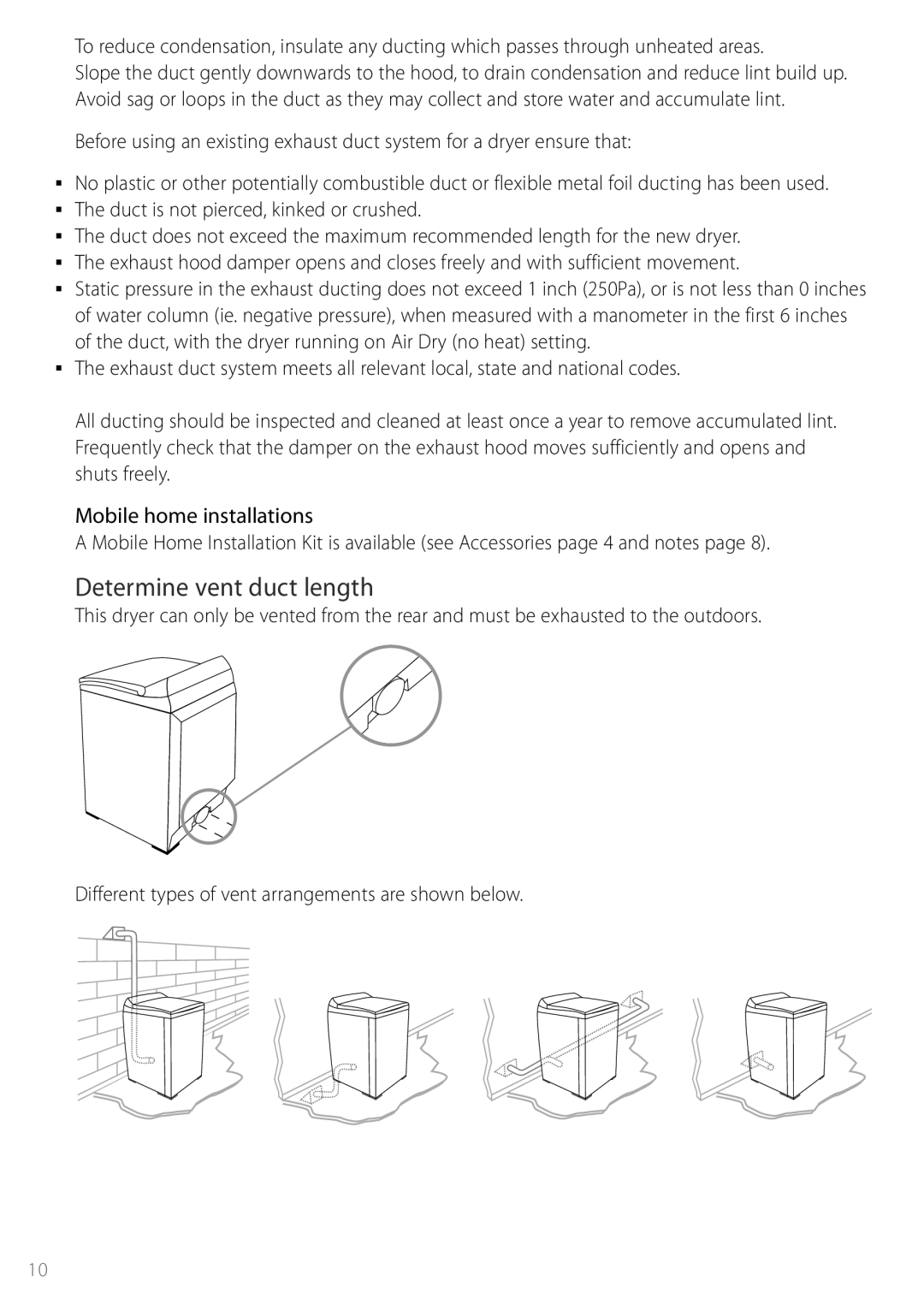

This dryer can only be vented from the rear and must be exhausted to the outdoors.

Different types of vent arrangements are shown below.

10