INSTALLATION OF PUMP, DROP PIPE, AND ASSOCIATED EQUIPMENT

Fig. 1 illustrates a typical well installation showing in ground components. Adhere to the following items when installing the pump and drop pipe:

1.Fasten the submersible cable to the drop pipe with clamps or appropriate tape every 10 ft. (3m) to prevent tangling and damage to the cable. The cable must remain slack when using plastic drop pipe to allow for stretching of pipe when installed in the well.

2.Take care not to scrape or pinch the submersible cable against the well casing.

3.Use an ohmmeter or megger to make insulation and continuity checks on the cable once the pump is installed. This locates any fault in the cable.

4.Make sure a check valve is installed immediately above the pump. Install additional check valves at 100’ (30m) intervals.

5.Install a torque arrestor just above the pump to prevent chafing the cable when pump anad pipe twist during starting and stopping.

6.Attach a safety cable to pump to prevent loss of pump if pipe should break.

7.Place a sanitary well seal or pitless adapter with an approved cover plate over top of well per manufacturers recommendations.

8.Keep pump at least 5’ (1.5m) from bottom of well and above well screen or casing perforations.

ELECTRICAL INFORMATION

1. | Employ a licensed electrician to perform the wiring. |

| All wiring must be done in accordance with applicable |

| national and local electrical codes. |

2. | Check that the power supply corresponds with the |

| electrical rating of the submersible motor and the |

| control box(if required). Make sure that the control box |

| electrical rating matches the motor electrical rating. |

3. | Every installation requires a fused disconnect switch |

| or circuit breaker. |

secondary power lines; it is not effective against direct hits.

6.Mount the control box in an area protected from rain, snow, direct sunlight or other high temperatures as this may cause tripping of the overload protector.

Also protect the control box from extreme cold (below

7.A

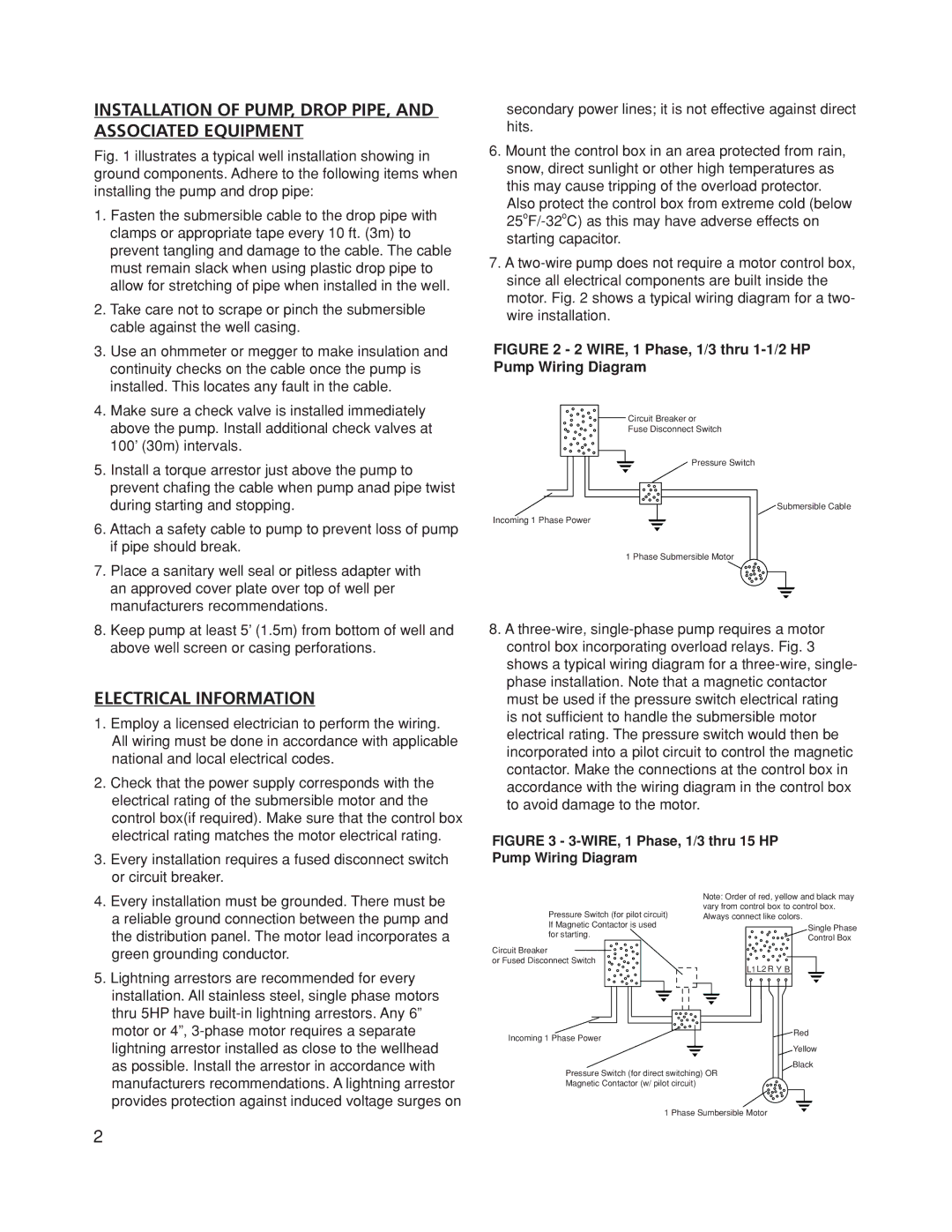

FIGURE 2 - 2 WIRE, 1 Phase, 1/3 thru 1-1/2 HP Pump Wiring Diagram

Circuit Breaker or

Fuse Disconnect Switch

Pressure Switch

Submersible Cable

Incoming 1 Phase Power

1 Phase Submersible Motor

8.A

FIGURE 3 - 3-WIRE, 1 Phase, 1/3 thru 15 HP Pump Wiring Diagram

4. Every installation must be grounded. There must be |

a reliable ground connection between the pump and |

the distribution panel. The motor lead incorporates a |

green grounding conductor. |

5. Lightning arrestors are recommended for every |

installation. All stainless steel, single phase motors |

thru 5HP have |

motor or 4”, |

lightning arrestor installed as close to the wellhead |

as possible. Install the arrestor in accordance with |

Pressure Switch (for pilot circuit) If Magnetic Contactor is used for starting.

Circuit Breaker

or Fused Disconnect Switch

Incoming 1 Phase Power

Note: Order of red, yellow and black may vary from control box to control box. Always connect like colors.

Single Phase

Control Box

L1 L2 R Y B

Red

Yellow

Black

manufacturers recommendations. A lightning arrestor |

provides protection against induced voltage surges on |

Pressure Switch (for direct switching) OR Magnetic Contactor (w/ pilot circuit)

1 Phase Sumbersible Motor

2