ATTENTION!

IMPORTANT INFORMATION FOR INSTALLERS OF THIS EQUIPMENT!

THIS EQUIPMENT IS INTENDED FOR INSTALLATION BY TECHNICALLY QUALIFIED PERSONNEL. FAILURE TO INSTALL IT IN COMPLIANCE WITH NATIONAL AND LOCAL ELECTRICAL CODES, AND WITH FRANKLIN ELECTRIC RECOMMENDATIONS, MAY RESULT IN ELECTRICAL SHOCK OR FIRE HAZARD, UNSATISFACTORY PERFORMANCE, AND EQUIPMENT FAILURE. FRANKLIN INSTALLATION INFORMATION IS AVAILABLE FROM PUMP MANUFACTURERS AND DISTRIBUTORS, AND DIRECTLY FROM FRANKLIN ELECTRIC. CALL FRANKLIN TOLL FREE

FUTURE REFERENCE.

![]() WARNING

WARNING

SERIOUS OR FATAL ELECTRICAL SHOCK MAY RESULT FROM FAILURE TO CONNECT THE MOTOR, CONTROL ENCLOSURES, METAL PLUMBING, AND ALL OTHER METAL NEAR THE MOTOR OR CABLE, TO THE POWER SUPPLY GROUND TERMINAL USING WIRE NO SMALLER THAN MOTOR CABLE WIRES. TO REDUCE RISK OF ELECTRICAL SHOCK, DISCONNECT POWER BEFORE WORKING ON OR AROUND THE WATER SYSTEM. DO NOT USE MOTOR IN SWIMMING AREAS.

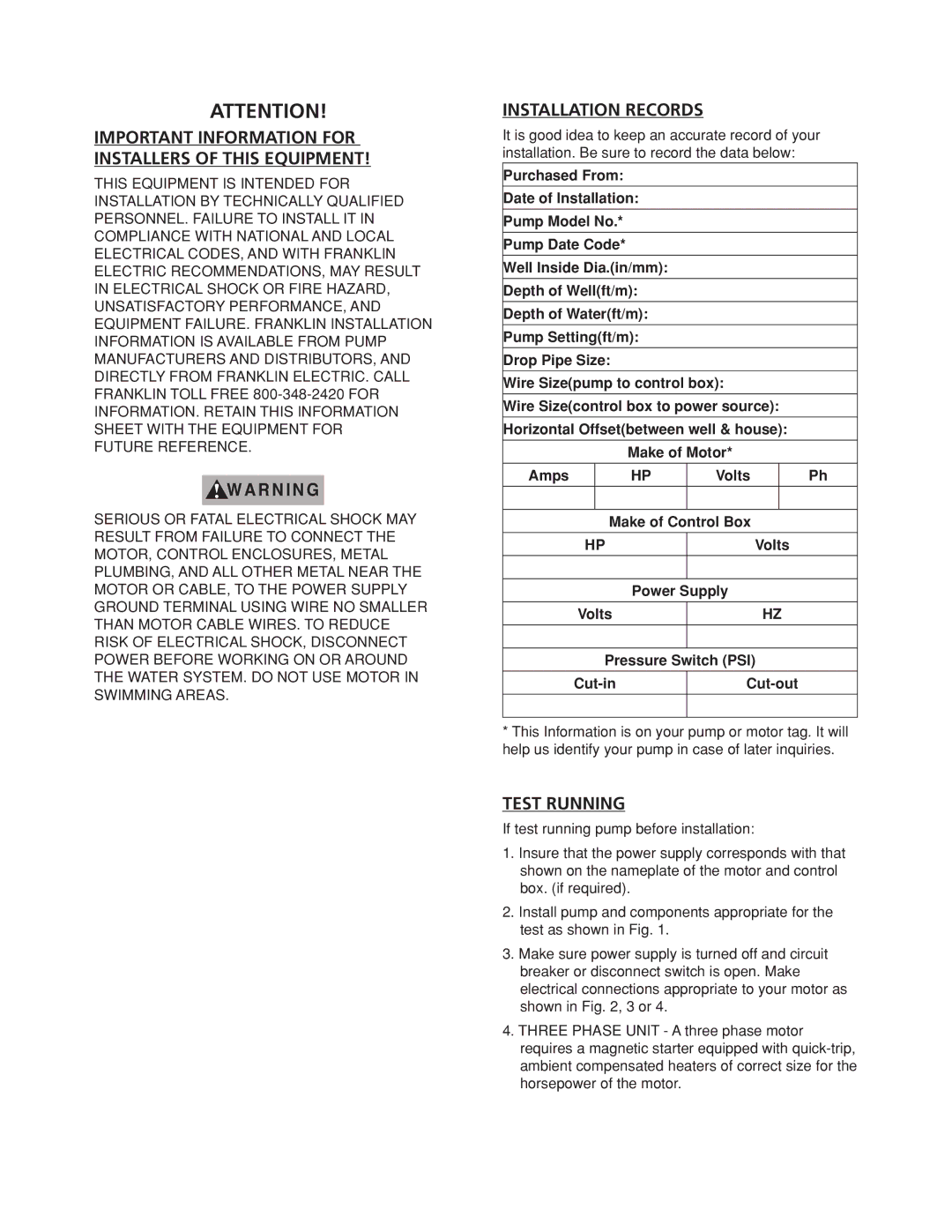

INSTALLATION RECORDS

It is good idea to keep an accurate record of your installation. Be sure to record the data below:

Purchased From:

Date of Installation:

Pump Model No.*

Pump Date Code*

Well Inside Dia.(in/mm):

Depth of Well(ft/m):

Depth of Water(ft/m):

Pump Setting(ft/m):

Drop Pipe Size:

Wire Size(pump to control box):

Wire Size(control box to power source):

Horizontal Offset(between well & house):

Make of Motor*

Amps |

| HP | Volts |

| Ph |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Make of Control Box |

|

| |

|

|

|

| ||

| HP |

| Volts | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Power Supply |

|

| |

|

|

|

| ||

| Volts |

| HZ | ||

|

|

|

|

|

|

|

|

|

|

|

|

Pressure Switch (PSI)

Cut-in Cut-out

*This Information is on your pump or motor tag. It will help us identify your pump in case of later inquiries.

TEST RUNNING

If test running pump before installation:

1.Insure that the power supply corresponds with that shown on the nameplate of the motor and control box. (if required).

2.Install pump and components appropriate for the test as shown in Fig. 1.

3.Make sure power supply is turned off and circuit breaker or disconnect switch is open. Make electrical connections appropriate to your motor as shown in Fig. 2, 3 or 4.

4.THREE PHASE UNIT - A three phase motor requires a magnetic starter equipped with