Document No. GEK-91696, Rev. D

Transportation

Isdiclos

Desiredorshouldpartiularproblemsariseth

Ordisclosureisstrictly

GEK-91696D

CONTENTS1150HPACDrillingMotor,Model5GEB22

Mtormodel

Toolsandmaterialsrequiredtoperformtheprocedures

ToTable9insection61.2.DrillMotorGeneral

Generaldrillingmotornformation

Inypicaloilwelldrillingindustryrigenvionments

Offsho

Issuitablefor

1150HPACDrillingMotor,Model5GEB22

Requir

Withstelcomponnts

Wihtheblowerandvari

GEK-91696D

1892 25º77

GEK-91696D

3331

9200

GD3000EACDriveSystem

NationalOilwellVarco

Type2400SeriesPart#109341withorwithoutasmoothinginductor

RossHill6ModelABBACS800manufacturedbyNOV

Grounding.ReferenceABSRulesforherentlyBuilndg

Lationoftheconductorsmachin

MotorCouplingandAlignment

Inhibitorinstallation,theexposedcomponents

Prtectthegroundstud,nut,andcablelugconnectionfromcorrosion

Goodalignmentwillbereturnedbearingsreduceddowntime

Belts

Clean

Atorto

Thiswill

Tweenthemachinesandthebase

Cooling

Meeti ngIP56

Recheckthe

Tothepowercomponentsofthe

PowerCableInspection

Orcircuit,ahigh

1150HPACDrilling

Replacemissinghardwareandtightenloosebolts

4Apply

Wat

13untilalltheRTD

Ing.Theinernal

Maycause

Claningdrill

Torlife

1150HPACDrillingMotor,Model5GEB22

Removethe

Trque

TheBackrotorthelockigjamnutsboltsawyfrmthebearingcap

Boltsand

Installcoverandsidepaneltocratethemotor

GEK-91696D

Footholeswiththe

Rust otherdefects

Thebcking

4Attach

GEK-91696D

Screw

Wooden

Hanc

CMPONENTIDENTIFICATIONofthispublicaio,unlers

± ±

1150HPACDrillingMotor,ModelGEK-5GEB2291696D

Bearingassembly

SupporttheweightoftheDE Head11with

Removaloftheconnectionend

Useanarborprssandfixturesto

Inspectthestatorcoilsandbusringsas

Examine

StatorCoilsand

Busringsfordamagedor

KgthCn

Eto,Clea

Bycuttingand

Requiringthe

Whichmust flatalongtheentirelenghofthejoint

Berialeliminatestheneedforflux

Outortofillvids

Diancanbeused

Erie,PA16531

Agent

ElectricalTetingIntroduction

Dair,looseneddebrismay

Proceduresforthebalance

Weightstotheendplate

Follow

Tohold

2InspectallCEbearingassemblycomponenttodebris

Proceduresforcompressedai

Umb

Sonnel.Enureallpersonnel

Page

Inner

Ensurethe

SshowninFigure10

Makgthe

DEBearingpilotandGuideStudsInstalled

GEK-91696D

Withthe

Levelthe

Avy-duty

Mountthestatorf

OnthefaceoftheConnectionEndCEoftherotorshaft5

Toch

3Zerothedial ReadingonthefaceoftheCErotorbearing34outerrace

Poitiontoavoiddamagetothe

Fthe

Repeattheminimumclearancecheckf

Thebearingrollerswillpublicationrollverthe

3Zerothedial

Fure13

Clampadial

Ingcap.Zerothe

Pass

Perfo

Threephasesshouldbebetween130and150

Followingsequence.Applied

Andcorrectthfitasfllows

Theshaft

Ontheshaft

Atthelarge

Ifnecssaryto

Theadvancwithin

Rkacrosstheendofshaft

Isonlyanesimateandshouldbe

Done

Prat

Alongthe

93A41

Unoutmasuredfromshafttoouterrace,eachend,in.mm

DrillMotorApplicationData

920012474

Drivendbearinggreaselubricationcapacity,ouncegram

Color

Minerallkali,OilViscosityat100F,37.74C,SSU

BasewithAntioxidant

RsistanceTimetoReach20psiDropat210F,Hr.Min 1000

1150HPACDrillingMotor,11

Inspectiondata

GEK1150-91696DHPACDrillingMotor,Model5GEB22

DEOuterSleeveRemovalToolAssembly6751547G4

GEK1150-91696DHPACDrillingMotor, Model 5GEB22

DEInnerBearingCapRemovalToolAssembly6751547G6

DEInnerSleeve RemovalToolAssembly 6751547G7

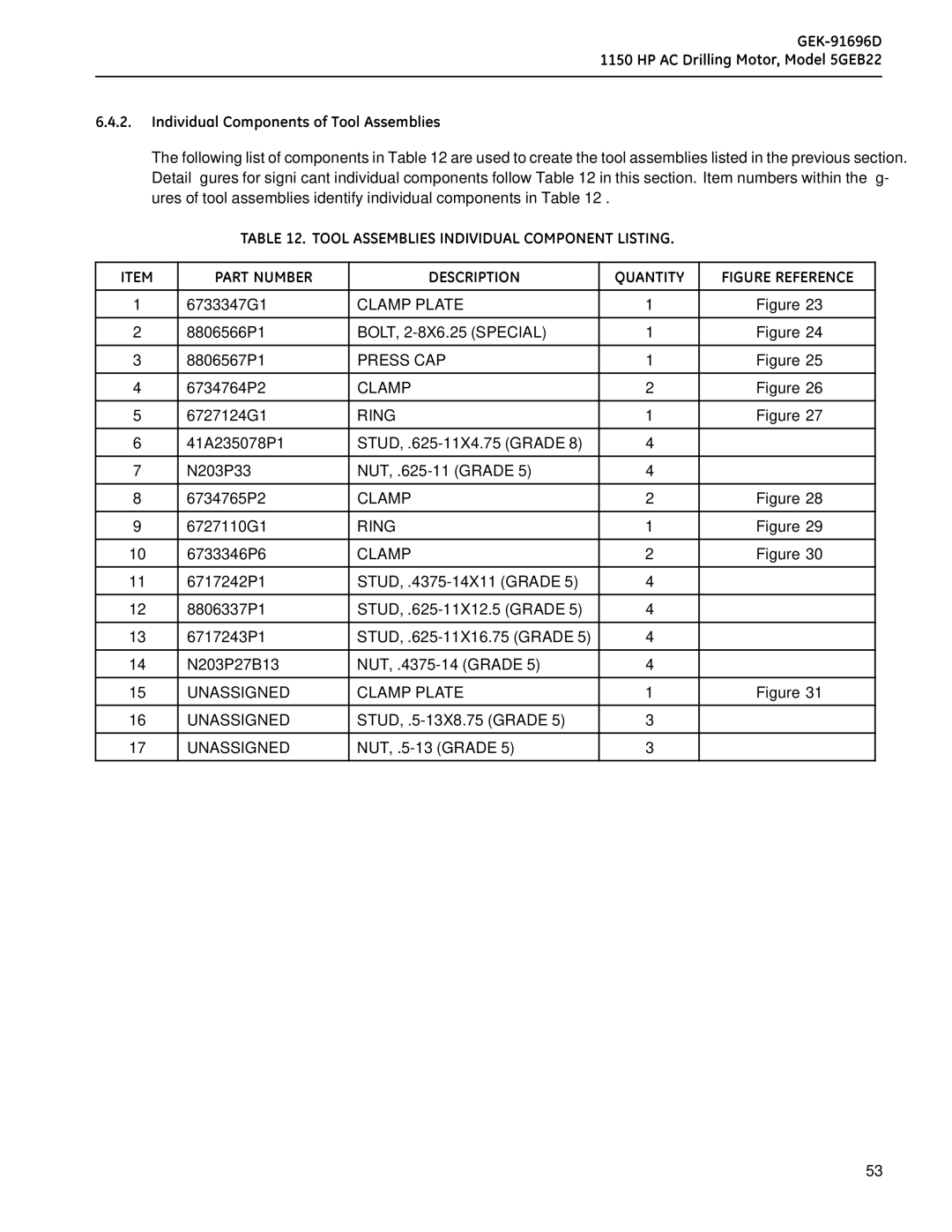

ThefllowinglistofcompoentsinT

41A235078P1

1X4.75GRADE8

IndividualCompnentsofToolAssemblies

1150HPACDrillingMotor,Model5GEB22

1150HPAC Drill ingMotor,ModelGEK-5GEB2291696D

GEK1150-91696DHPACDrillingMotor, Model5GEB22

Ring6727124G1Item5

1150GEK-91696DHPACDrillingMotor, Model5GEB22

Ring6727110G1Item9

Clamp6733346P6Item10

N22P39040

B5511G1

093 9P14

THICKX3.9IDX5.5OD

GEK1150-91696DHPACDrillingMotor,1Model5GEB22

1150HPACDrillingMotor, 1.Model00GEK-5GEB2291696D

HubRemovalToolBackingPlate41B535119G1

GEK1150-91696DHPAC DrillingMotor,Model5GEB223.125

BearingNutSpannerWrench9945228

CEDummyBearingCap41C689896

1150HPACDrillingMotor,ModelGEK-5GEB2291696D

DEBearingGuide

DEDummyBearingCap6796493P3

HubInstallationAdvanceGage

70NWREV091030621--98,098,2MGC/DGKGMDPABGAS