GE10 Gas Turbines

The GE10 is a 12 MW range heavy-duty gas turbine available in both single shaft and two shaft versions. It is the evolution of the field-proven PGT10A and incorporates the latest in aerodynamic design in a compact and versatile package arrangement. The design of the GE10 has been highly refined based on the extensive experience gained operating in all types of environments. There are over one hundred units running under conditions ranging from the cold of Alaska and Siberia to the heat of the desert and the humidity of the tropics.

Its efficiency and operational flexibility make the GE10 a cost-effective choice for all applications. The gas generator consists of an 11 stage, high efficiency, axial-flow compressor and a single combustion chamber capable of burning a great variety of fuels. Maximum commonality has been maintained between the single and twin shaft models. Both units use the same gas generator. The two shaft engine is obtained by simply removing the third stage turbine from the single shaft unit and adding a two-stage low pressure power turbine. This feature is particularly beneficial in reducing operating and maintenance costs in installations where mixed operation is required.

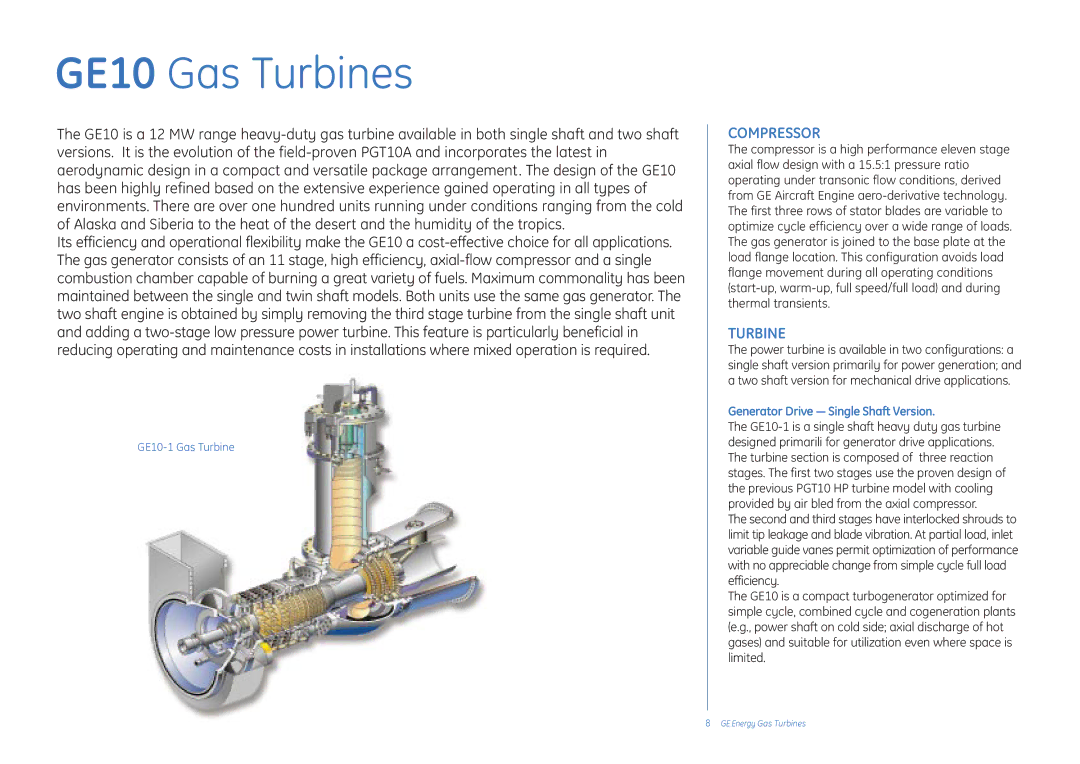

GE10-1 Gas Turbine

COMPRESSOR

The compressor is a high performance eleven stage axial flow design with a 15.5:1 pressure ratio operating under transonic flow conditions, derived from GE Aircraft Engine aero-derivative technology. The first three rows of stator blades are variable to optimize cycle efficiency over a wide range of loads. The gas generator is joined to the base plate at the load flange location. This configuration avoids load flange movement during all operating conditions (start-up, warm-up, full speed/full load) and during thermal transients.

TURBINE

The power turbine is available in two configurations: a single shaft version primarily for power generation; and a two shaft version for mechanical drive applications.

Generator Drive — Single Shaft Version.

The GE10-1 is a single shaft heavy duty gas turbine designed primarili for generator drive applications. The turbine section is composed of three reaction stages. The first two stages use the proven design of the previous PGT10 HP turbine model with cooling provided by air bled from the axial compressor.

The second and third stages have interlocked shrouds to limit tip leakage and blade vibration. At partial load, inlet variable guide vanes permit optimization of performance with no appreciable change from simple cycle full load efficiency.

The GE10 is a compact turbogenerator optimized for simple cycle, combined cycle and cogeneration plants (e.g., power shaft on cold side; axial discharge of hot gases) and suitable for utilization even where space is limited.