Section 3 — Operation

Guardian

2.6ADJUSTING THE REGULATOR

(NATURAL GAS ONLY)

Although the generator has been factory set to pro- vide maximum power, it may be necessary in some areas to adjust this setting. Because natural gas has different BTU or power content across the country the engine may not perform as designed.

If experiencing engine problems at high or full load conditions follow these steps. It will require a fre- quency meter to perform this procedure.

1. Turn off utility power to the main distribution panel in the house. This can be done by switching the service main breaker to the off or open position.

2. Allow the generator to start before loading the generator. Confirm the

3. Turn on appliances, lights, pumps, etc., that are on the emergency circuits in an attempt to fully load the generator. Be cautious not to overload the generator. Use the following chart as a guide:

| Unit | 120 Volts | 240 Volts |

|

| 7 kW | 50.0 amps | 25.0 amps |

|

| 12 kW | 100.0 amps | 50.0 amps |

|

| 15 kW | 108.3 amps | 54.2 amps |

|

|

|

|

|

|

4. When full load has been achieved. Connect a fre- quency meter to the output lugs of the generator’s main line circuit breaker.

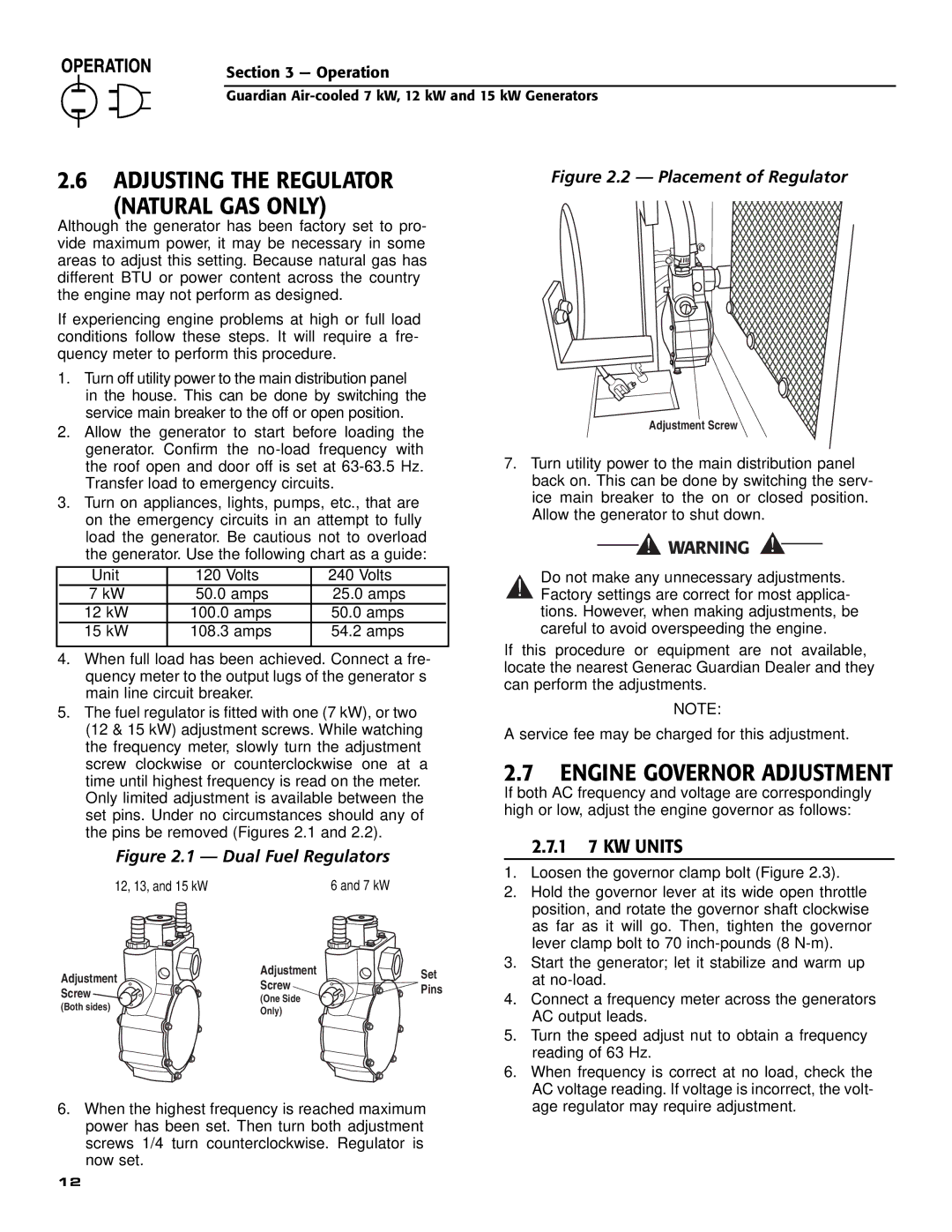

5. The fuel regulator is fitted with one (7 kW), or two (12 & 15 kW) adjustment screws. While watching the frequency meter, slowly turn the adjustment screw clockwise or counterclockwise one at a time until highest frequency is read on the meter. Only limited adjustment is available between the set pins. Under no circumstances should any of the pins be removed (Figures 2.1 and 2.2).

Figure 2.1 — Dual Fuel Regulators

12, 13, and 15 kW | 6 and 7 kW |

990 | 410 |

Adjustment | Adjustment | Set | |

Screw | |||

Pins | |||

Screw | |||

(One Side | |||

| |||

(Both sides) |

| ||

Only) |

| ||

|

|

6.When the highest frequency is reached maximum power has been set. Then turn both adjustment screws 1/4 turn counterclockwise. Regulator is now set.

12

Figure 2.2 — Placement of Regulator

Adjustment Screw

7.Turn utility power to the main distribution panel back on. This can be done by switching the serv- ice main breaker to the on or closed position. Allow the generator to shut down.

Do not make any unnecessary adjustments.

!Factory settings are correct for most applica- tions. However, when making adjustments, be careful to avoid overspeeding the engine.

If this procedure or equipment are not available, locate the nearest Generac Guardian Dealer and they can perform the adjustments.

NOTE:

A service fee may be charged for this adjustment.

2.7ENGINE GOVERNOR ADJUSTMENT

If both AC frequency and voltage are correspondingly high or low, adjust the engine governor as follows:

◆2.7.1 7 KW UNITS

1.Loosen the governor clamp bolt (Figure 2.3).

2.Hold the governor lever at its wide open throttle position, and rotate the governor shaft clockwise as far as it will go. Then, tighten the governor lever clamp bolt to 70

3.Start the generator; let it stabilize and warm up at

4.Connect a frequency meter across the generators AC output leads.

5.Turn the speed adjust nut to obtain a frequency reading of 63 Hz.

6.When frequency is correct at no load, check the AC voltage reading. If voltage is incorrect, the volt- age regulator may require adjustment.