Section 2 — Installation

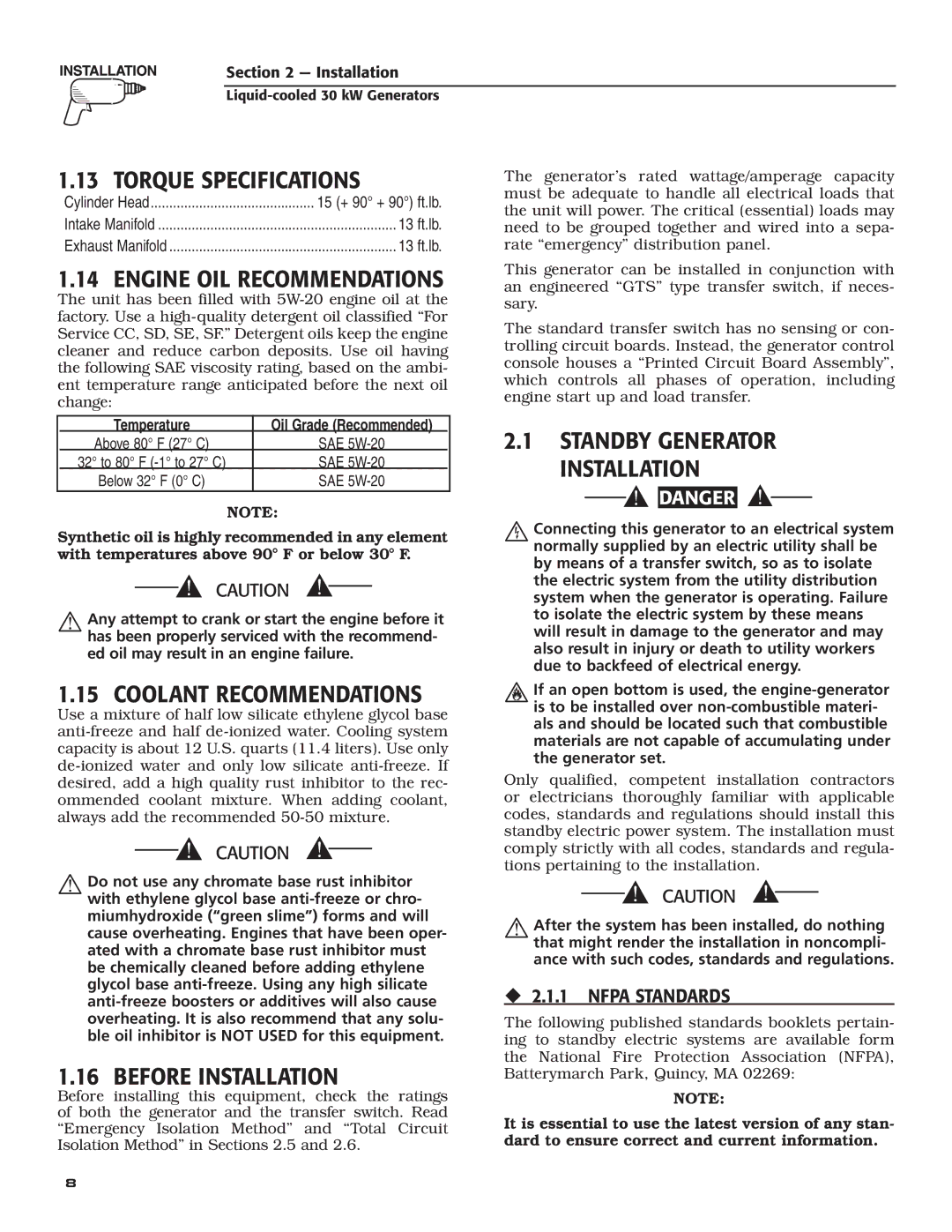

1.13 TORQUE SPECIFICATIONS

Cylinder Head | 15 (+ 90° + 90°) ft.lb. |

Intake Manifold | 13 ft.lb. |

Exhaust Manifold | 13 ft.lb. |

1.14 ENGINE OIL RECOMMENDATIONS

The unit has been filled with

The generator’s rated wattage/amperage capacity must be adequate to handle all electrical loads that the unit will power. The critical (essential) loads may need to be grouped together and wired into a sepa- rate “emergency” distribution panel.

This generator can be installed in conjunction with an engineered “GTS” type transfer switch, if neces- sary.

The standard transfer switch has no sensing or con- trolling circuit boards. Instead, the generator control console houses a “Printed Circuit Board Assembly”, which controls all phases of operation, including engine start up and load transfer.

| Temperature | Oil Grade (Recommended) |

|

| Above 80° F (27° C) | SAE |

|

| 32° to 80° F | SAE |

|

| Below 32° F (0° C) | SAE |

|

NOTE:

Synthetic oil is highly recommended in any element with temperatures above 90° F or below 30° F.

Any attempt to crank or start the engine before it has been properly serviced with the recommend- ed oil may result in an engine failure.

2.1STANDBY GENERATOR

INSTALLATION

![]()

![]() DANGER

DANGER

Connecting this generator to an electrical system normally supplied by an electric utility shall be by means of a transfer switch, so as to isolate the electric system from the utility distribution system when the generator is operating. Failure to isolate the electric system by these means will result in damage to the generator and may also result in injury or death to utility workers due to backfeed of electrical energy.

1.15 COOLANT RECOMMENDATIONS

Use a mixture of half low silicate ethylene glycol base

Do not use any chromate base rust inhibitor with ethylene glycol base

1.16 BEFORE INSTALLATION

Before installing this equipment, check the ratings of both the generator and the transfer switch. Read “Emergency Isolation Method” and “Total Circuit Isolation Method” in Sections 2.5 and 2.6.

If an open bottom is used, the

Only qualified, competent installation contractors or electricians thoroughly familiar with applicable codes, standards and regulations should install this standby electric power system. The installation must comply strictly with all codes, standards and regula- tions pertaining to the installation.

After the system has been installed, do nothing that might render the installation in noncompli- ance with such codes, standards and regulations.

2.1.1 NFPA STANDARDS

The following published standards booklets pertain- ing to standby electric systems are available form the National Fire Protection Association (NFPA), Batterymarch Park, Quincy, MA 02269:

NOTE:

It is essential to use the latest version of any stan- dard to ensure correct and current information.

8