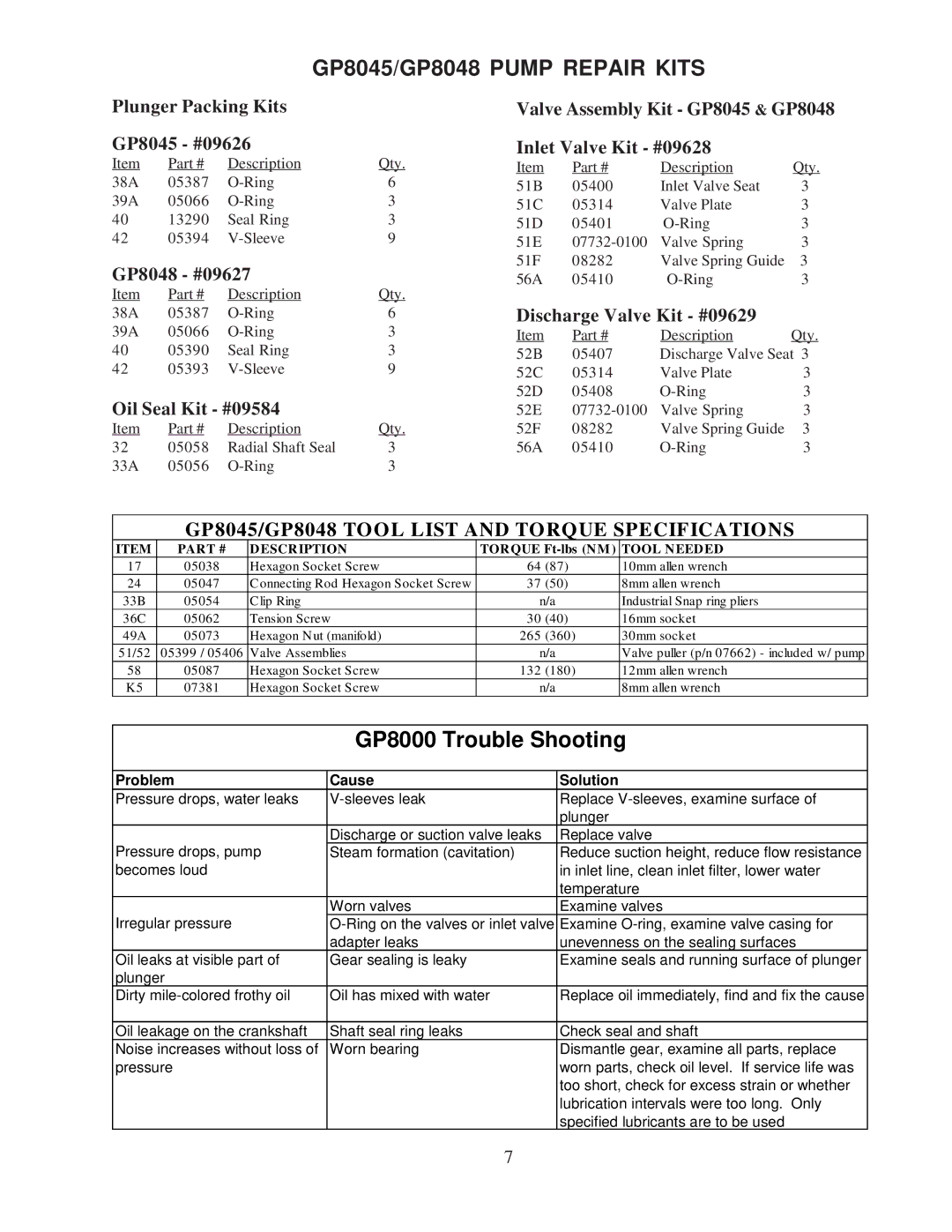

GP8045/GP8048 PUMP REPAIR KITS

Plunger Packing Kits |

| Valve Assembly Kit - GP8045 & GP8048 | |||||

GP8045 - #09626 |

| Inlet Valve Kit - #09628 |

| ||||

Item | Part # | Description | Qty. | Item | Part # | Description | Qty. |

38A | 05387 | 6 | 51B | 05400 | Inlet Valve Seat | 3 | |

39A | 05066 | 3 | 51C | 05314 | Valve Plate | 3 | |

40 | 13290 | Seal Ring | 3 | 51D | 05401 | 3 | |

42 | 05394 | 9 | 51E | Valve Spring | 3 | ||

GP8048 - #09627 |

| 51F | 08282 | Valve Spring Guide | 3 | ||

| 56A | 05410 | 3 | ||||

Item | Part # | Description | Qty. |

|

|

|

|

38A | 05387 | 6 | Discharge Valve Kit - #09629 |

| |||

39A | 05066 | 3 | Item | Part # | Description | Qty. | |

40 | 05390 | Seal Ring | 3 | 52B | 05407 | Discharge Valve Seat 3 | |

42 | 05393 | 9 | 52C | 05314 | Valve Plate | 3 | |

Oil Seal Kit - #09584 |

| 52D | 05408 | 3 | |||

| 52E | Valve Spring | 3 | ||||

Item | Part # | Description | Qty. | 52F | 08282 | Valve Spring Guide | 3 |

32 | 05058 | Radial Shaft Seal | 3 | 56A | 05410 | 3 | |

33A | 05056 | 3 |

|

|

|

| |

GP8045/GP8048 TOOL LIST AND TORQUE SPECIFICATIONS

ITEM | PART # | DESCRIPTION | TORQUE | TOOL NEEDED | |

17 | 05038 | Hexagon Socket Screw | 64 | (87) | 10mm allen wrench |

24 | 05047 | Connecting Rod Hexagon Socket Screw | 37 | (50) | 8mm allen wrench |

33B | 05054 | Clip Ring | n/a | Industrial Snap ring pliers | |

36C | 05062 | Tension Screw | 30 | (40) | 16mm socket |

49A | 05073 | Hexagon Nut (manifold) | 265 | (360) | 30mm socket |

51/52 | 05399 / 05406 | Valve Assemblies | n/a | Valve puller (p/n 07662) - included w/ pump | |

58 | 05087 | Hexagon Socket Screw | 132 | (180) | 12mm allen wrench |

K5 | 07381 | Hexagon Socket Screw | n/a | 8mm allen wrench | |

GP8000 Trouble Shooting

Problem | Cause | Solution |

Pressure drops, water leaks | Replace | |

|

| plunger |

Pressure drops, pump | Discharge or suction valve leaks | Replace valve |

Steam formation (cavitation) | Reduce suction height, reduce flow resistance | |

becomes loud |

| in inlet line, clean inlet filter, lower water |

|

| temperature |

Irregular pressure | Worn valves | Examine valves |

Examine | ||

| adapter leaks | unevenness on the sealing surfaces |

Oil leaks at visible part of | Gear sealing is leaky | Examine seals and running surface of plunger |

plunger |

|

|

Dirty | Oil has mixed with water | Replace oil immediately, find and fix the cause |

|

|

|

Oil leakage on the crankshaft | Shaft seal ring leaks | Check seal and shaft |

Noise increases without loss of | Worn bearing | Dismantle gear, examine all parts, replace |

pressure |

| worn parts, check oil level. If service life was |

|

| too short, check for excess strain or whether |

|

| lubrication intervals were too long. Only |

|

| specified lubricants are to be used |

7