Accessories | A |

We recommend that you buy all your accessories such as nails from the store where you bought the tool. Use good quality accessories with a

Unpacking

Due to modern mass production techniques, it is unlikely that your power tool is faulty or that a part is missing. If you find anything wrong, do not operate the tool until the parts have been replaced or the fault has been rectified. Failure to do so could result in serious personal injury.

Assembly

The ACALN Allnailer® is packed fully assembled.

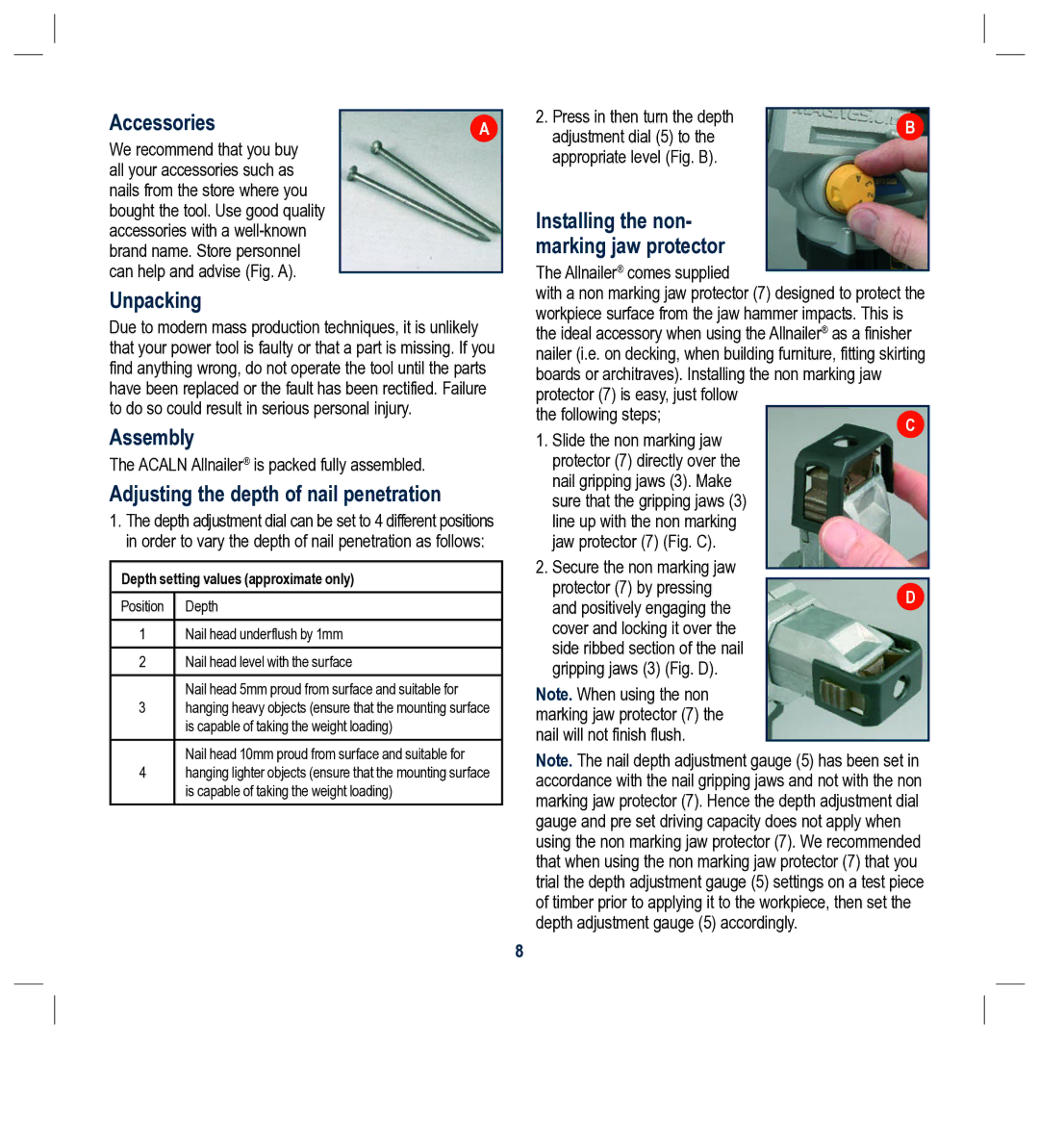

Adjusting the depth of nail penetration

1.The depth adjustment dial can be set to 4 different positions in order to vary the depth of nail penetration as follows:

Depth setting values (approximate only)

Position | Depth |

1Nail head underflush by 1mm

2Nail head level with the surface

Nail head 5mm proud from surface and suitable for

3hanging heavy objects (ensure that the mounting surface is capable of taking the weight loading)

Nail head 10mm proud from surface and suitable for

4hanging lighter objects (ensure that the mounting surface is capable of taking the weight loading)

2. Press in then turn the depth

adjustment dial (5) to theB appropriate level (Fig. B).

Installing the non- marking jaw protector

The Allnailer® comes supplied

with a non marking jaw protector (7) designed to protect the workpiece surface from the jaw hammer impacts. This is the ideal accessory when using the Allnailer® as a finisher

nailer (i.e. on decking, when building furniture, fitting skirting | ||

boards or architraves). Installing the non marking jaw |

| |

protector (7) is easy, just follow |

| |

the following steps; |

| C |

1. Slide the non marking jaw |

| |

|

| |

protector (7) directly over the |

|

|

nail gripping jaws (3). Make |

|

|

sure that the gripping jaws (3) |

|

|

line up with the non marking |

|

|

jaw protector (7) (Fig. C). |

|

|

2. Secure the non marking jaw |

|

|

|

| |

protector (7) by pressing |

| D |

and positively engaging the |

| |

|

| |

cover and locking it over the |

|

|

side ribbed section of the nail |

|

|

gripping jaws (3) (Fig. D). |

|

|

Note. When using the non |

|

|

marking jaw protector (7) the |

|

|

nail will not finish flush. |

|

|

Note. The nail depth adjustment gauge (5) has been set in accordance with the nail gripping jaws and not with the non marking jaw protector (7). Hence the depth adjustment dial gauge and pre set driving capacity does not apply when using the non marking jaw protector (7). We recommended that when using the non marking jaw protector (7) that you trial the depth adjustment gauge (5) settings on a test piece of timber prior to applying it to the workpiece, then set the depth adjustment gauge (5) accordingly.

8