WARNING. Be sure to tighten | E | |

the bevel lock before making | ||

| ||

a cut. Failure to do so could |

| |

result in the saw arm moving |

| |

during the cut and cause |

| |

serious personal injury. |

|

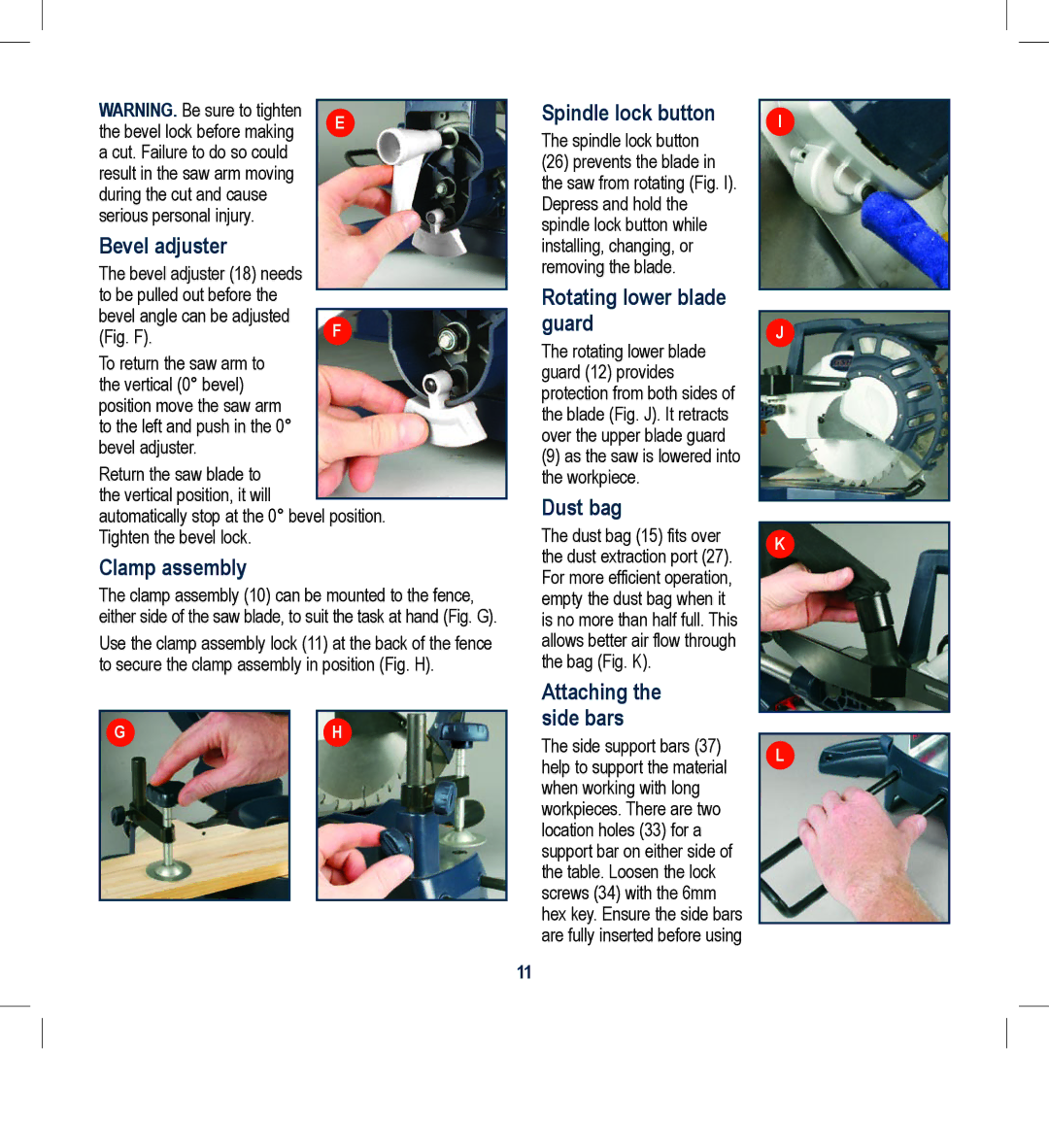

Bevel adjuster |

| |

The bevel adjuster (18) needs |

| |

to be pulled out before the |

| |

| ||

bevel angle can be adjusted |

| |

F | ||

(Fig. F). | ||

| ||

To return the saw arm to |

| |

the vertical (0° bevel) |

| |

position move the saw arm |

| |

to the left and push in the 0° |

| |

bevel adjuster. |

|

Return the saw blade to the vertical position, it will

automatically stop at the 0° bevel position. Tighten the bevel lock.

Clamp assembly

The clamp assembly (10) can be mounted to the fence, either side of the saw blade, to suit the task at hand (Fig. G).

Use the clamp assembly lock (11) at the back of the fence to secure the clamp assembly in position (Fig. H).

G |

| H |

|

|

|

Spindle lock button

The spindle lock button

(26)prevents the blade in the saw from rotating (Fig. I). Depress and hold the spindle lock button while installing, changing, or removing the blade.

Rotating lower blade guard

The rotating lower blade guard (12) provides protection from both sides of the blade (Fig. J). It retracts over the upper blade guard

(9)as the saw is lowered into the workpiece.

Dust bag

The dust bag (15) fits over the dust extraction port (27). For more efficient operation, empty the dust bag when it is no more than half full. This allows better air flow through the bag (Fig. K).

Attaching the side bars

The side support bars (37) help to support the material when working with long workpieces. There are two location holes (33) for a support bar on either side of the table. Loosen the lock screws (34) with the 6mm hex key. Ensure the side bars are fully inserted before using

I

J

K

L

11